| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

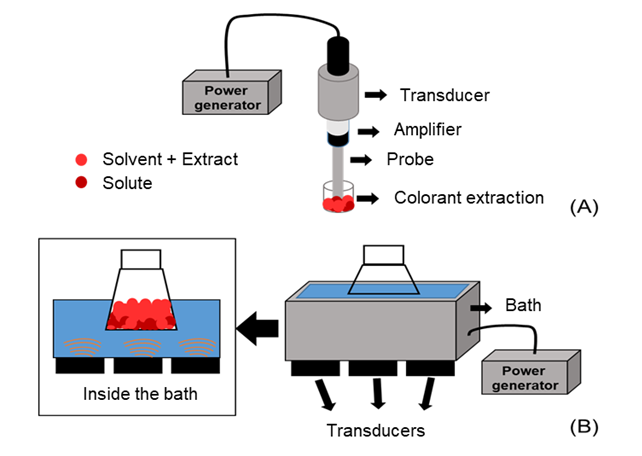

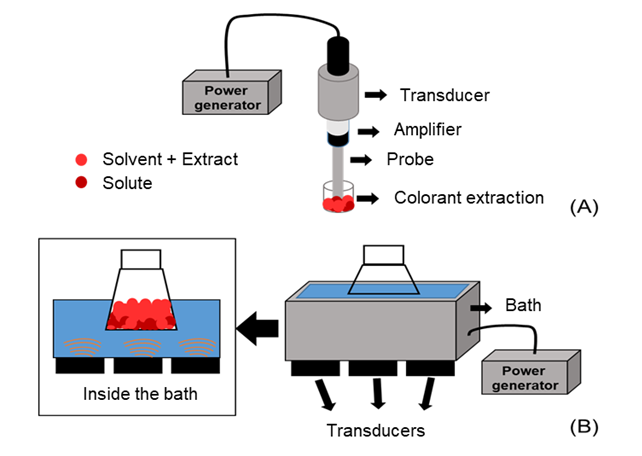

Ultrasonic extraction is a widely used technique for extracting CBD (cannabidiol) from hemp plants. The process involves the use of an ultrasonic sonicator, which uses high-frequency sound waves to create cavitation in the extraction solvent, facilitating the breakdown of plant material and enhancing the release of the target compound.

Here are the basic steps involved in CBD extraction using ultrasonic sonication:

1. Harvest and dry the hemp plant material: The plant material is first harvested and dried to remove excess moisture.

2. Grind the plant material: The plant material is then ground into small particles to increase its surface area, allowing for better extraction.

3. Prepare the solvent: A suitable solvent, such as ethanol or CO2, is chosen and prepared for use.

4. Combine the solvent and plant material: The plant material is then combined with the solvent in a container and stirred to ensure even distribution.

5. Sonicate the mixture: The mixture is then subjected to ultrasonic waves from the sonicator. The ultrasonic energy causes the solvent to penetrate the plant material more effectively, breaking down cell walls and enhancing the release of CBD.

6. Filter the extract: After sonication, the mixture is filtered to remove any solid plant material, leaving behind the CBD extract in the solvent.

7. Purify the extract: The extract is then further purified, typically through a process of evaporation, to remove the solvent and concentrate the CBD.

| Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1600Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used to extract flavors, colors, and bioactive compounds from food products, such as fruits, vegetables, herbs, and spices. Examples include the extraction of antioxidants from grape seeds, carotenoids from tomatoes, and caffeine from coffee beans.

And in the production of drugs and natural products to extract active ingredients from plant materials. Examples include the extraction of paclitaxel from the bark of the Pacific yew tree and the extraction of ginsenosides from ginseng roots.

Also it is used in the production of cosmetic products, such as perfumes, essential oils, and natural fragrances. Ultrasonic extraction is particularly useful for extracting fragrances and essential oils from delicate plant materials, such as flowers and leaves.

Ultrasonic extraction offers several advantages over traditional extraction methods, including shorter extraction times, higher yields, and the ability to use less solvent. Additionally, ultrasonic extraction is a more sustainable and environmentally friendly process, as it requires less energy and produces less waste.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic extraction is a widely used technique for extracting CBD (cannabidiol) from hemp plants. The process involves the use of an ultrasonic sonicator, which uses high-frequency sound waves to create cavitation in the extraction solvent, facilitating the breakdown of plant material and enhancing the release of the target compound.

Here are the basic steps involved in CBD extraction using ultrasonic sonication:

1. Harvest and dry the hemp plant material: The plant material is first harvested and dried to remove excess moisture.

2. Grind the plant material: The plant material is then ground into small particles to increase its surface area, allowing for better extraction.

3. Prepare the solvent: A suitable solvent, such as ethanol or CO2, is chosen and prepared for use.

4. Combine the solvent and plant material: The plant material is then combined with the solvent in a container and stirred to ensure even distribution.

5. Sonicate the mixture: The mixture is then subjected to ultrasonic waves from the sonicator. The ultrasonic energy causes the solvent to penetrate the plant material more effectively, breaking down cell walls and enhancing the release of CBD.

6. Filter the extract: After sonication, the mixture is filtered to remove any solid plant material, leaving behind the CBD extract in the solvent.

7. Purify the extract: The extract is then further purified, typically through a process of evaporation, to remove the solvent and concentrate the CBD.

| Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1600Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used to extract flavors, colors, and bioactive compounds from food products, such as fruits, vegetables, herbs, and spices. Examples include the extraction of antioxidants from grape seeds, carotenoids from tomatoes, and caffeine from coffee beans.

And in the production of drugs and natural products to extract active ingredients from plant materials. Examples include the extraction of paclitaxel from the bark of the Pacific yew tree and the extraction of ginsenosides from ginseng roots.

Also it is used in the production of cosmetic products, such as perfumes, essential oils, and natural fragrances. Ultrasonic extraction is particularly useful for extracting fragrances and essential oils from delicate plant materials, such as flowers and leaves.

Ultrasonic extraction offers several advantages over traditional extraction methods, including shorter extraction times, higher yields, and the ability to use less solvent. Additionally, ultrasonic extraction is a more sustainable and environmentally friendly process, as it requires less energy and produces less waste.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.