| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000

SP

8543709990

An ultrasonic homogenizer for emulsification utilizes high-frequency ultrasonic waves to create cavitation, producing intense shear forces that efficiently disperse and uniformly mix liquids. This process is particularly effective for creating stable emulsions, where immiscible liquids like oil and water are combined into a homogeneous mixture. The ultrasonic homogenizer's precision and efficiency make it invaluable in various fields such as pharmaceuticals, food and beverage production, cosmetics, and nanotechnology. In laboratories, it is used for sample preparation, cell disruption, and the synthesis of nanoparticles. In industrial settings, it supports large-scale production with consistent results. Its advantages include rapid processing times, scalability, and the ability to handle a wide range of viscosities, making it a versatile tool for both research and manufacturing.

Model | SPS20-500S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type |

Pharmaceuticals:

Preparation of emulsions for drug delivery systems.Synthesis of nanoparticles for targeted drug delivery.

Cell disruption for extracting intracellular compounds.

Food and Beverage:

Homogenization of dairy products, sauces, and dressings.Enhancement of the texture and stability of beverages.

Emulsification of flavors, essential oils, and vitamins.

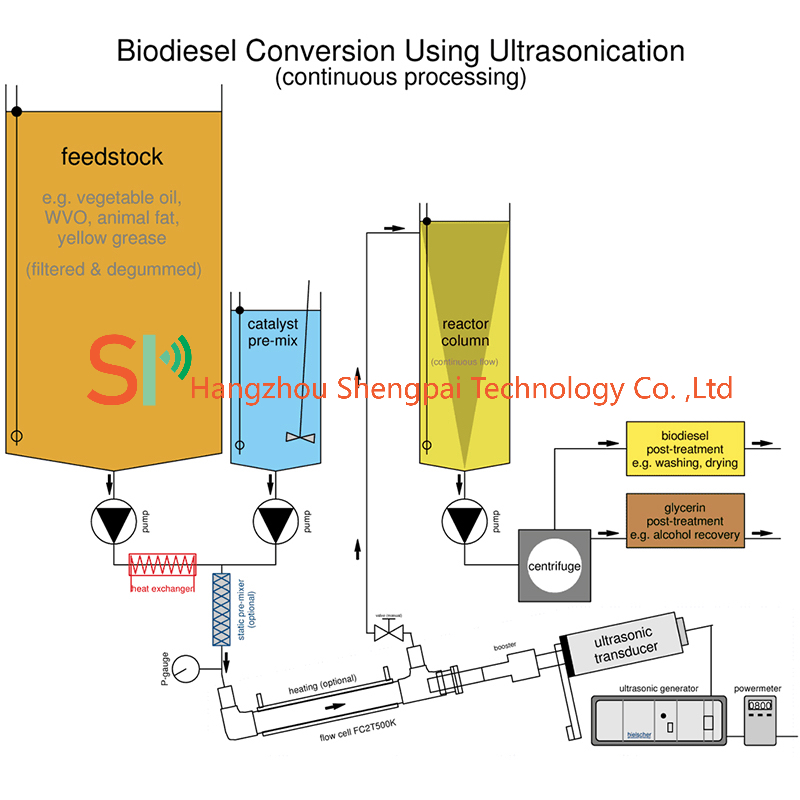

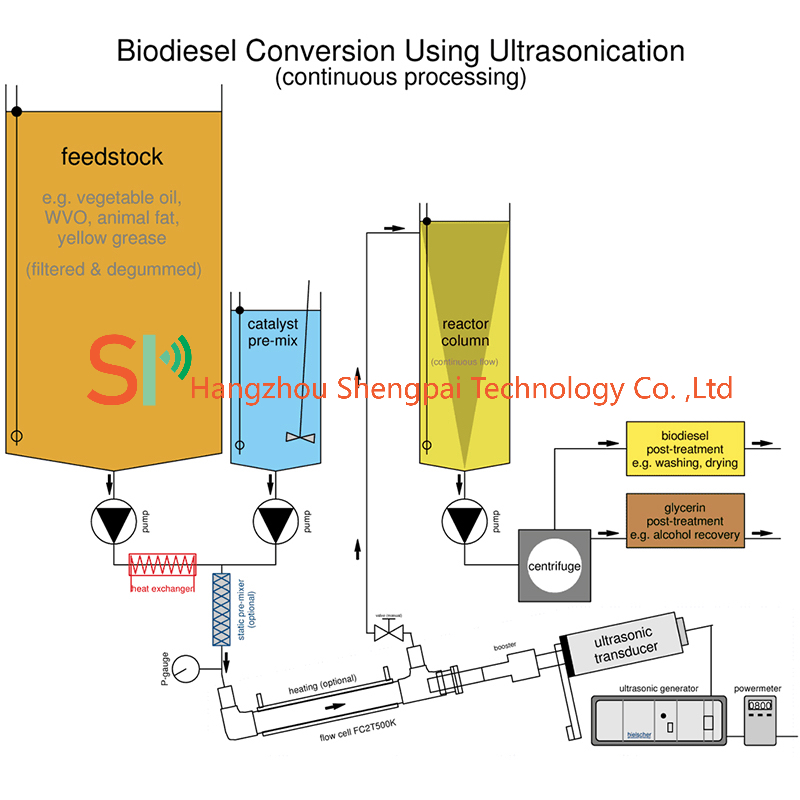

Emulsification of immiscible liquids for chemical reactions.Production of biodiesel through the emulsification of oils and alcohols.Enhancement of chemical reaction rates by increasing surface area.

1. The emulsification quality is high. The average droplet size of the formed emulsion is small, which can reach 0.2~2um. The droplet size distribution range is narrow, up to 0.1~10um. The concentration is high, the concentration of pure emulsion can reach 30%, adding emulsifier can reach 70%.

2. The emulsification is stable, you can produce stable emulsions without or with less emulsifiers, and some can be stable for several months or even more than half a year, with low energy consumption, high production efficiency and low cost.

3. The type of emulsion can be controlled. Under certain sound field conditions, both oil-in-water and water-in-oil emulsions can be prepared. However, it is impossible to achieve mechanical emulsification. Only the properties of emulsifiers can control the type of emulsion. For example, when toluene is emulsified in water, one type of emulsion can be formed under low sound intensity conditions, and another type of emulsion can be formed under high sound intensity conditions.

4. Low power required to produce emulsion.

5. The type of emulsion can be controlled. Using ultrasonic emulsification, under certain sound field conditions, both O/W (oil-in-water) and W/O (water-in-oil) emulsions can be prepared; however, mechanical emulsification is impossible, and only the properties of the emulsifier can control the emulsion type.

Customers' evalution as follow:

Ultrasonic homogenizers receive positive reviews for their efficiency and versatility in various applications. Users appreciate their ability to produce consistent and stable emulsions, disperse nanoparticles, and disrupt cells for extraction purposes. They are praised for their rapid processing times, scalability, and the capability to handle a wide range of viscosities. Many reviews highlight their effectiveness in laboratory and industrial settings, noting their precision and ease of use. Overall, ultrasonic homogenizers are valued for their high performance and reliability across multiple fields.

An ultrasonic homogenizer for emulsification utilizes high-frequency ultrasonic waves to create cavitation, producing intense shear forces that efficiently disperse and uniformly mix liquids. This process is particularly effective for creating stable emulsions, where immiscible liquids like oil and water are combined into a homogeneous mixture. The ultrasonic homogenizer's precision and efficiency make it invaluable in various fields such as pharmaceuticals, food and beverage production, cosmetics, and nanotechnology. In laboratories, it is used for sample preparation, cell disruption, and the synthesis of nanoparticles. In industrial settings, it supports large-scale production with consistent results. Its advantages include rapid processing times, scalability, and the ability to handle a wide range of viscosities, making it a versatile tool for both research and manufacturing.

Model | SPS20-500S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type |

Pharmaceuticals:

Preparation of emulsions for drug delivery systems.Synthesis of nanoparticles for targeted drug delivery.

Cell disruption for extracting intracellular compounds.

Food and Beverage:

Homogenization of dairy products, sauces, and dressings.Enhancement of the texture and stability of beverages.

Emulsification of flavors, essential oils, and vitamins.

Emulsification of immiscible liquids for chemical reactions.Production of biodiesel through the emulsification of oils and alcohols.Enhancement of chemical reaction rates by increasing surface area.

1. The emulsification quality is high. The average droplet size of the formed emulsion is small, which can reach 0.2~2um. The droplet size distribution range is narrow, up to 0.1~10um. The concentration is high, the concentration of pure emulsion can reach 30%, adding emulsifier can reach 70%.

2. The emulsification is stable, you can produce stable emulsions without or with less emulsifiers, and some can be stable for several months or even more than half a year, with low energy consumption, high production efficiency and low cost.

3. The type of emulsion can be controlled. Under certain sound field conditions, both oil-in-water and water-in-oil emulsions can be prepared. However, it is impossible to achieve mechanical emulsification. Only the properties of emulsifiers can control the type of emulsion. For example, when toluene is emulsified in water, one type of emulsion can be formed under low sound intensity conditions, and another type of emulsion can be formed under high sound intensity conditions.

4. Low power required to produce emulsion.

5. The type of emulsion can be controlled. Using ultrasonic emulsification, under certain sound field conditions, both O/W (oil-in-water) and W/O (water-in-oil) emulsions can be prepared; however, mechanical emulsification is impossible, and only the properties of the emulsifier can control the emulsion type.

Customers' evalution as follow:

Ultrasonic homogenizers receive positive reviews for their efficiency and versatility in various applications. Users appreciate their ability to produce consistent and stable emulsions, disperse nanoparticles, and disrupt cells for extraction purposes. They are praised for their rapid processing times, scalability, and the capability to handle a wide range of viscosities. Many reviews highlight their effectiveness in laboratory and industrial settings, noting their precision and ease of use. Overall, ultrasonic homogenizers are valued for their high performance and reliability across multiple fields.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.