| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000

SP

8543709990

Ultrasonic liquid processors, commonly referred to as "sonicators," disrupt tissues and cells through cavitation and ultrasonic waves. Basically, an ultrasonic homogenizer has a tip which very rapidly vibrates, causing bubbles in the surrounding solution to rapidly form and collapse. This creates shear and shock waves which tear apart cells and particles.

Ultrasonic liquid processors are great for breaking apart cells and subcellular structures in suspension. They are not good for homogenizing intact tissue. Other applications include creating emulsions, dispersing nanoparticles, and reducing the size of particles in suspension. Sonicators generate a significant amount of heat so they may not work well with temperature-sensitive samples.

Uncertain if an ultrasonic is the right homogenizer for your application? Pls kindly let us know, we can provide assistance.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic homogenizing for Nano materials attracted the attention of scientists, researchers and engineers of almost any branches as nano-sized particles show unique characteristics. Their physical properties such as optical and magnetic properties, specific heats, melting points, and surface reactivity offer high potentials for material with extraordinary strengths. But the smaller particles, the more difficult becomes treatment. Ultrasonic homogenizer is often the best method to effect nano particles effectively. Mostly, high power ultrasonic homogenizer are the only efficient way to achieve the desired milling and dispersing results of nano particles such as nanotubes, graphene, metal oxides etc.

The ultrasonic homogenizing system effects on biological and microbiological systems are manifold: Dispersing & Homogenizing, cell and tissue lysis (e.g. bacteria, yeast, viruses, algae…) & extraction of intracellular materials such as proteins, ribosomes, RNA, lipids, peptides…, plant cell transformation.

1. Ultrasonic liquid processor produce small particle/droplet and narrow distribution curves.

2. Ultrasonic liquid processor can handle high concentrations of solids.

3. The ultrasonic liquid processor can prepare stable suspensions, dispersions and emulsions.

4. Ultrasonic liquid processor can be precisely controlled because important parameters (e.g., amplitude, power) can be affected and adjusted.

5. Ultrasonic liquid processor is very effective, energy saving, easy to operate and safe.

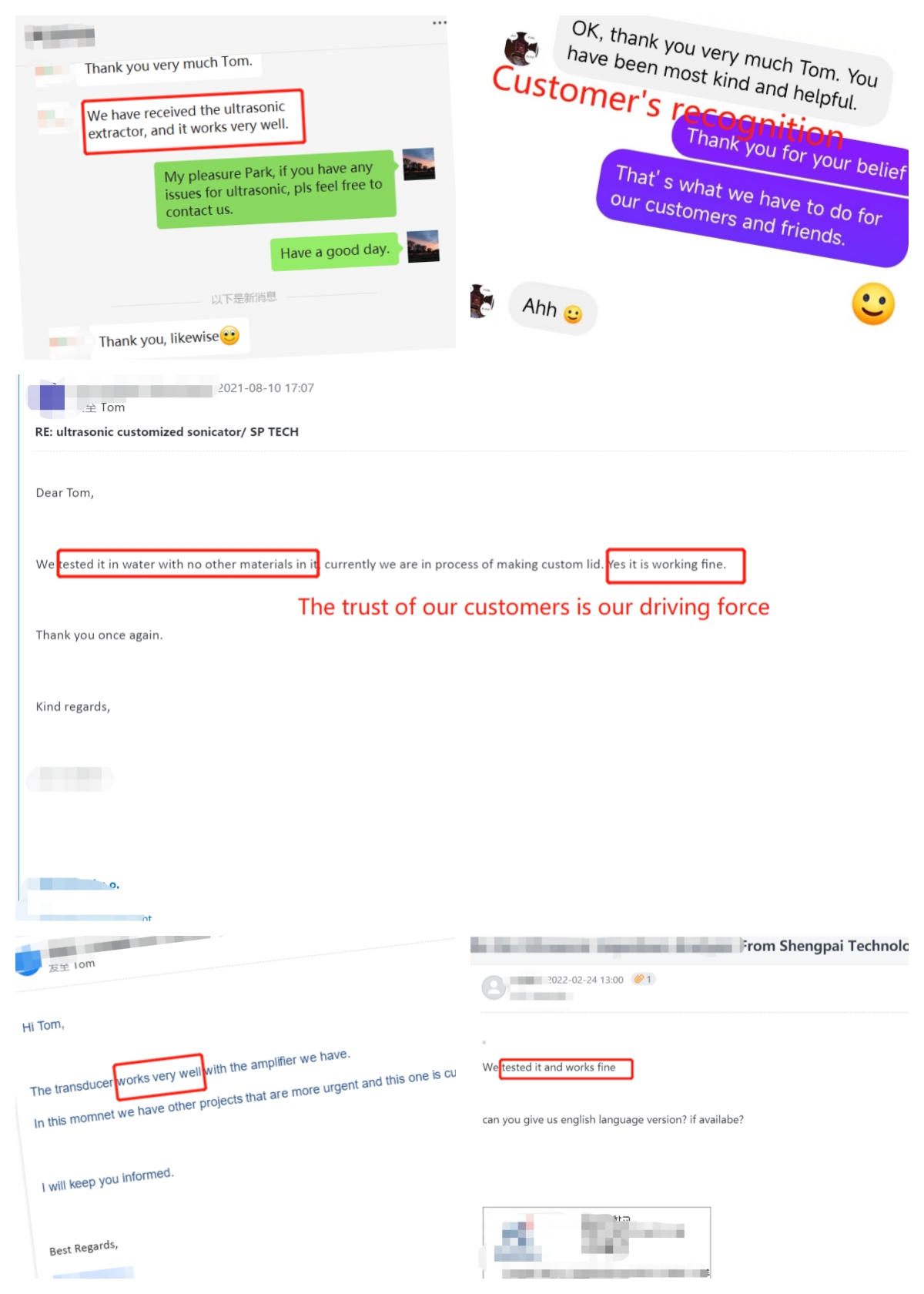

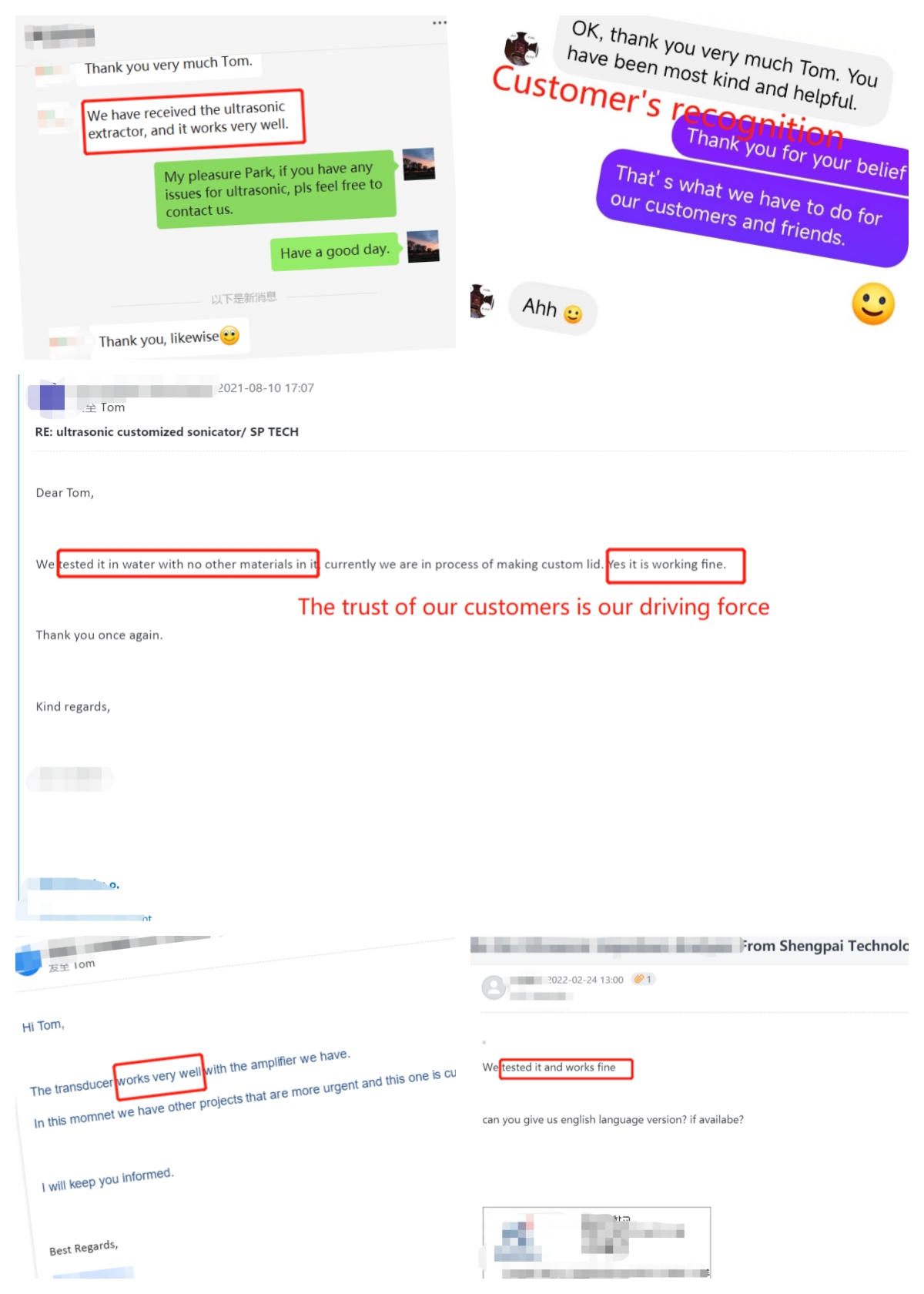

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic liquid processors, commonly referred to as "sonicators," disrupt tissues and cells through cavitation and ultrasonic waves. Basically, an ultrasonic homogenizer has a tip which very rapidly vibrates, causing bubbles in the surrounding solution to rapidly form and collapse. This creates shear and shock waves which tear apart cells and particles.

Ultrasonic liquid processors are great for breaking apart cells and subcellular structures in suspension. They are not good for homogenizing intact tissue. Other applications include creating emulsions, dispersing nanoparticles, and reducing the size of particles in suspension. Sonicators generate a significant amount of heat so they may not work well with temperature-sensitive samples.

Uncertain if an ultrasonic is the right homogenizer for your application? Pls kindly let us know, we can provide assistance.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic homogenizing for Nano materials attracted the attention of scientists, researchers and engineers of almost any branches as nano-sized particles show unique characteristics. Their physical properties such as optical and magnetic properties, specific heats, melting points, and surface reactivity offer high potentials for material with extraordinary strengths. But the smaller particles, the more difficult becomes treatment. Ultrasonic homogenizer is often the best method to effect nano particles effectively. Mostly, high power ultrasonic homogenizer are the only efficient way to achieve the desired milling and dispersing results of nano particles such as nanotubes, graphene, metal oxides etc.

The ultrasonic homogenizing system effects on biological and microbiological systems are manifold: Dispersing & Homogenizing, cell and tissue lysis (e.g. bacteria, yeast, viruses, algae…) & extraction of intracellular materials such as proteins, ribosomes, RNA, lipids, peptides…, plant cell transformation.

1. Ultrasonic liquid processor produce small particle/droplet and narrow distribution curves.

2. Ultrasonic liquid processor can handle high concentrations of solids.

3. The ultrasonic liquid processor can prepare stable suspensions, dispersions and emulsions.

4. Ultrasonic liquid processor can be precisely controlled because important parameters (e.g., amplitude, power) can be affected and adjusted.

5. Ultrasonic liquid processor is very effective, energy saving, easy to operate and safe.

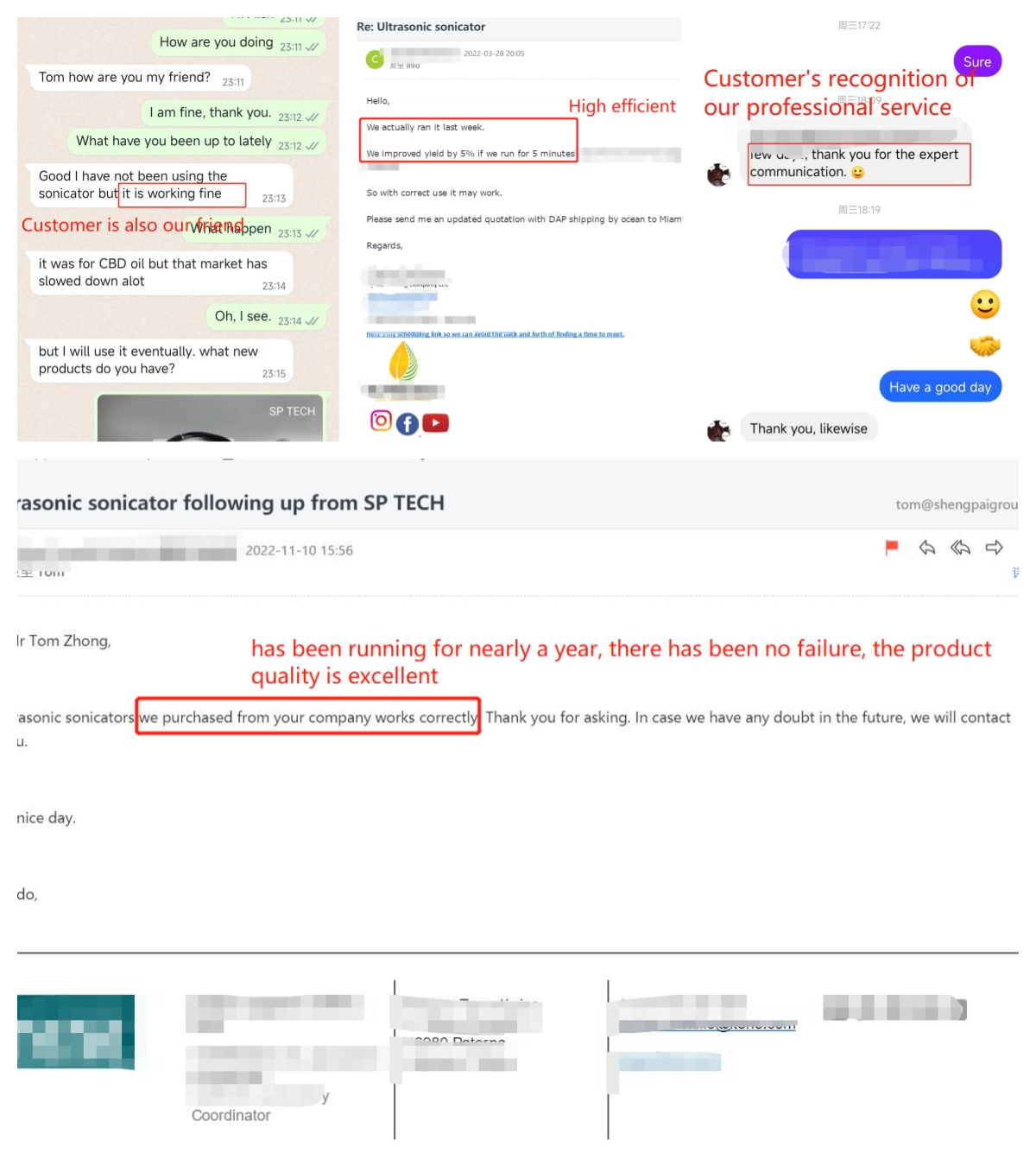

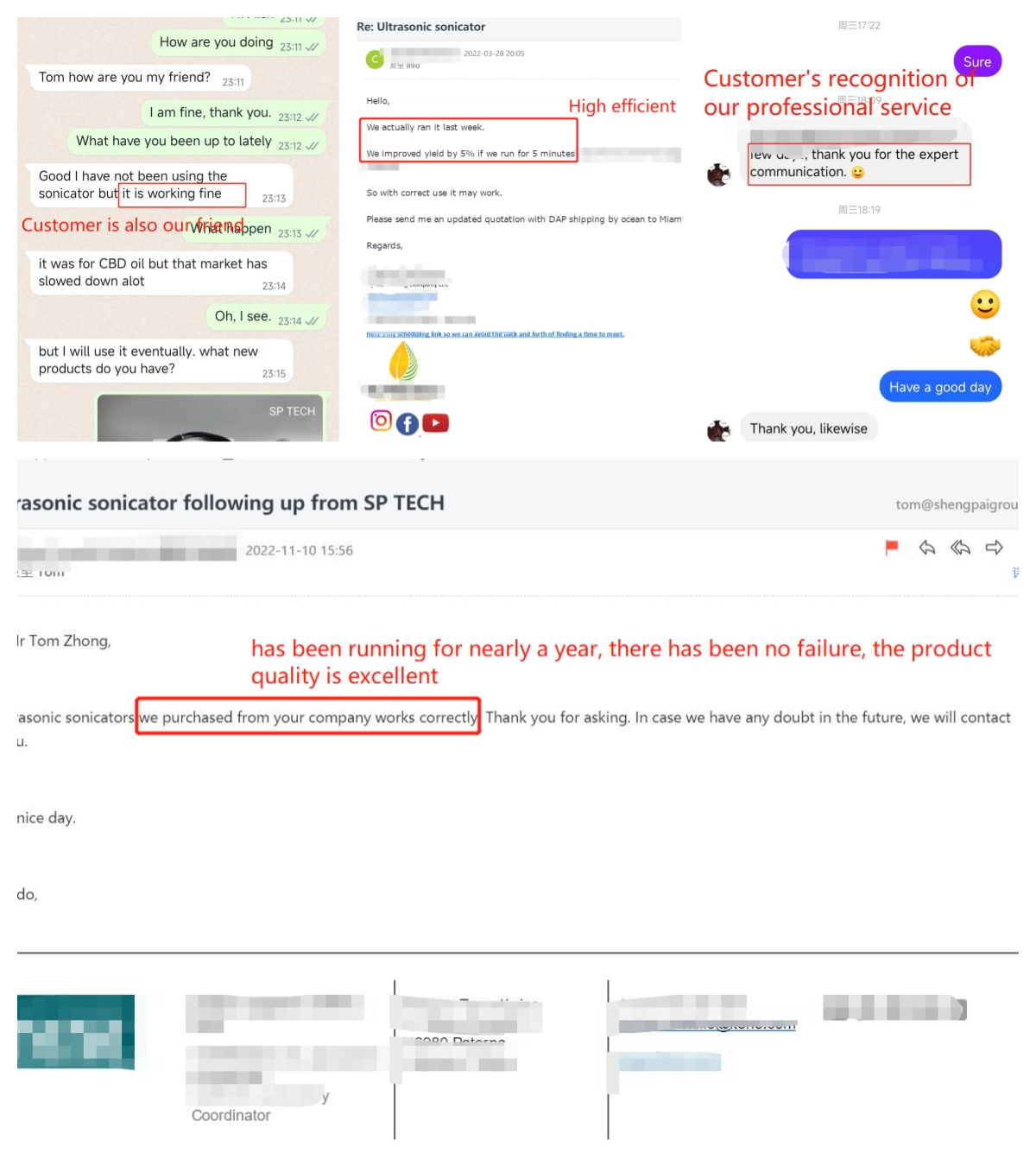

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.