| Availability: | |

|---|---|

| Quantity: | |

SPS20-1600S

SP

8543709990

An ultrasonic homogenizer is an advanced mechanical device designed to break down and emulsify liquids through high-frequency sound waves. This technology has applications in various fields such as pharmaceuticals, biotechnology, food and beverage processing, materials science, and chemical engineering. The device consists of three main components: an ultrasonic generator, a probe (also known as a horn or sonotrode), and a sample container.

Ultrasonic Generator

The ultrasonic generator is the core of the system, responsible for producing high-frequency electrical energy, typically at around 20 kHz. It converts standard electrical power into these high-frequency pulses, setting the stage for the homogenization process.

Probe (Horn/Sonotrode)

This high-frequency electrical energy is then transmitted to the probe, which is usually made from durable materials like titanium. The probe vibrates at the same high frequency, and its tip is immersed in the sample container, transferring ultrasonic energy efficiently into the liquid.

Sample Container

The sample container holds the liquid sample to be processed. It varies in size and shape depending on the volume and nature of the sample, accommodating the probe and withstanding the intense vibrations generated during the process.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

1. High yields

2. Superior Quality

3. Full Spectrum Extracts

4. Rapid Process

5. Compatible with Any Solvent

6. Easy and Safe to Operate

7. Linear Scalability

8. Environmental-Friendly

9. Fast RoI

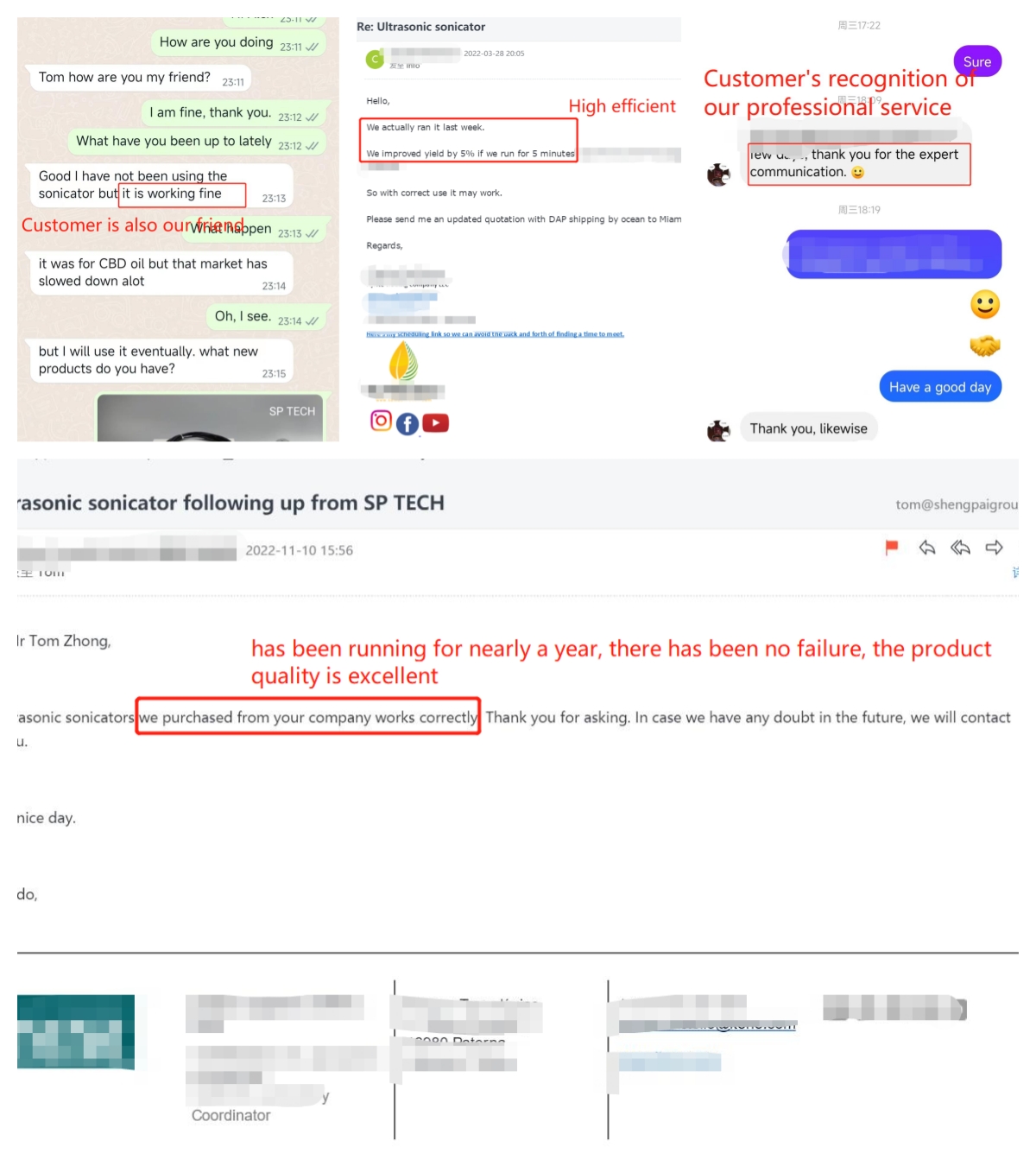

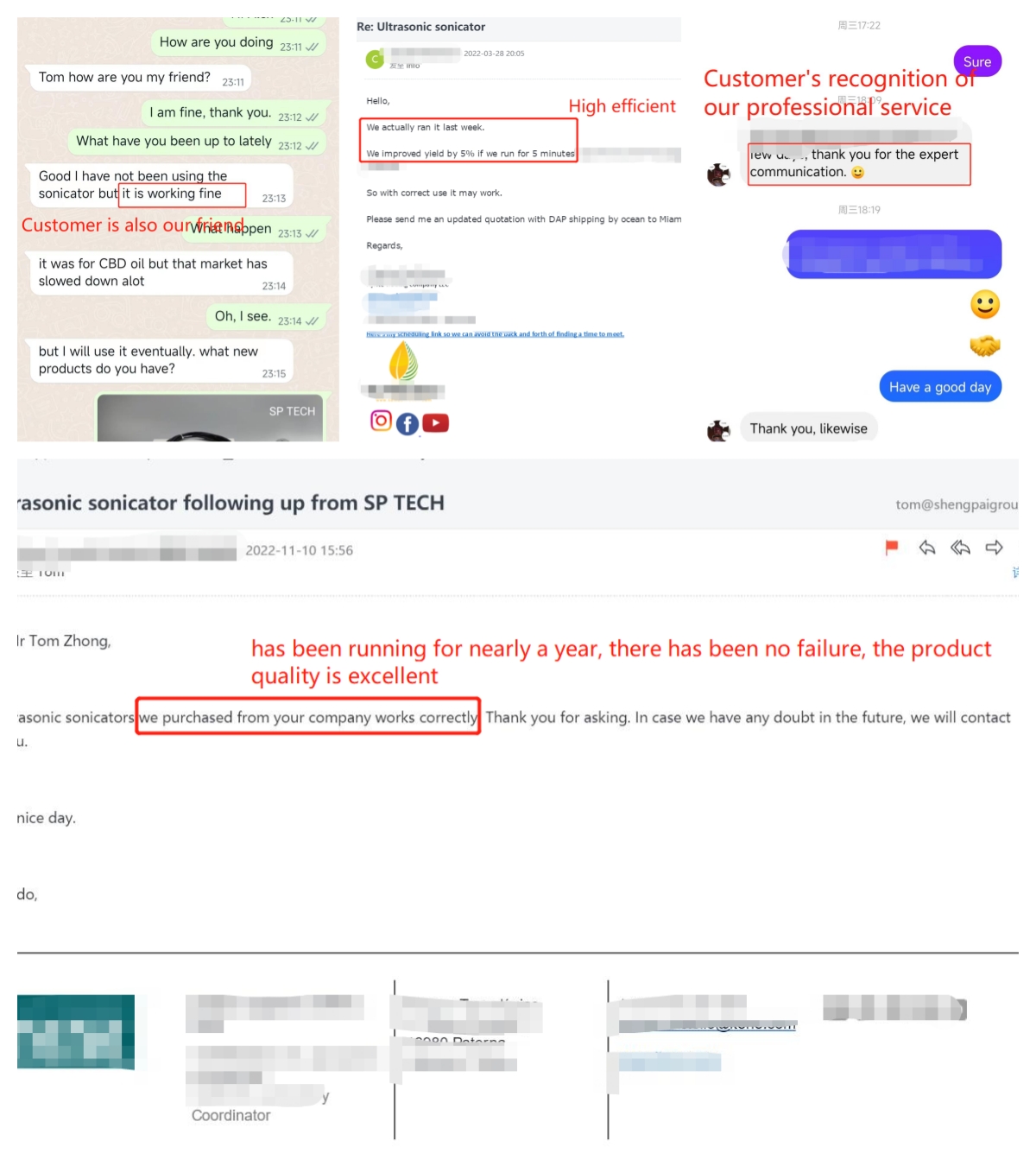

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

An ultrasonic homogenizer is an advanced mechanical device designed to break down and emulsify liquids through high-frequency sound waves. This technology has applications in various fields such as pharmaceuticals, biotechnology, food and beverage processing, materials science, and chemical engineering. The device consists of three main components: an ultrasonic generator, a probe (also known as a horn or sonotrode), and a sample container.

Ultrasonic Generator

The ultrasonic generator is the core of the system, responsible for producing high-frequency electrical energy, typically at around 20 kHz. It converts standard electrical power into these high-frequency pulses, setting the stage for the homogenization process.

Probe (Horn/Sonotrode)

This high-frequency electrical energy is then transmitted to the probe, which is usually made from durable materials like titanium. The probe vibrates at the same high frequency, and its tip is immersed in the sample container, transferring ultrasonic energy efficiently into the liquid.

Sample Container

The sample container holds the liquid sample to be processed. It varies in size and shape depending on the volume and nature of the sample, accommodating the probe and withstanding the intense vibrations generated during the process.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

1. High yields

2. Superior Quality

3. Full Spectrum Extracts

4. Rapid Process

5. Compatible with Any Solvent

6. Easy and Safe to Operate

7. Linear Scalability

8. Environmental-Friendly

9. Fast RoI

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.