| Availability: | |

|---|---|

| Quantity: | |

35K Telsonic Replacement

SP

8543709990

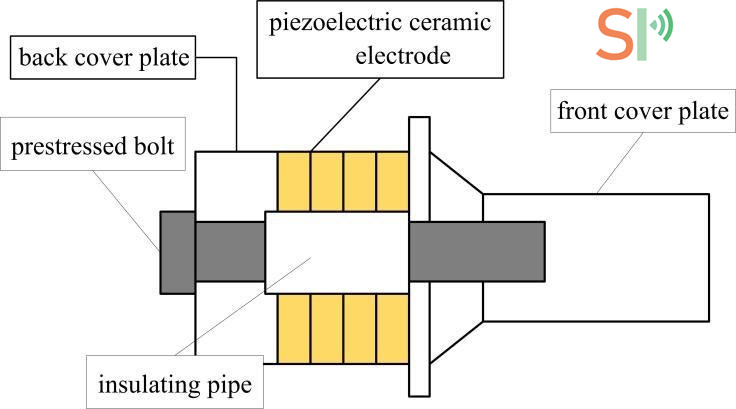

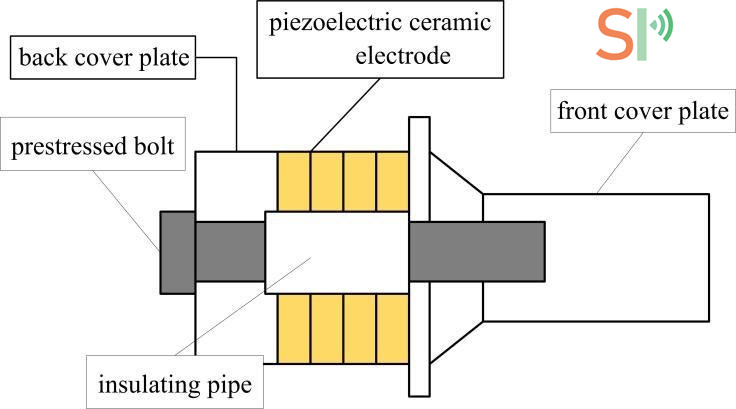

The ultrasonic transducer is mainly composed of a central piezoelectric ceramic element, front and rear metal covers, pre-stressed screws, electrode pads and insulating tubes. The specific composition is shown in the figure below.

The ultrasonic transducer is mainly composed of a central piezoelectric ceramic element, front and rear metal covers, pre-stressed screws, electrode pads and insulating tubes. The specific composition is shown in the figure below.

Back driver: The thick cylindrical element at the back of the piezoelectric transducer. The back driver abuts the rear-most ceramic and applies preload pressure, typically via a stacking bolt.

Electrodes: A thin electrically conductive disk placed between adjacent piezoelectric ceramics of a transducer. The transducer driving voltage is applied between these electrodes.

Front driver: Transmitting the transducer's ultrasonic energy to the horn or tool head, the front driver usually includes a mounting flange for connecting the housing.

Stack bolt: The bolt(s) used to sandwich the ceramics between the front and back drivers, thereby forming a resonant unit. When the bolt is tightened, it applies a compressive prestress to the ceramics.

Piezoelectric ceramic:Piezoelectric ceramics are the heart of the transducer. A component that converts the electrical signal of an ultrasonic generator into linear mechanical vibration.

Model | 35K Telsonic Replacement |

Frequency | 35Khz |

Output power | 1200Watt |

Joint bolt | M8*1.25 |

Ceramic disc Diameter | 25mm |

Quantity of Ceramic discs | 4pcs |

Capacitance | 4nF |

Application | Welding machine |

Ultrasonic transducer,ultrasonic generator and ultrasonic horn constitute a whole ultrasonic system, which can be widely used to do welding in various kinds of industries.

Applied Industries:

Automobile industry, electric industry, medical industry, household appliance industry,

non-woven fabric, clothing, packing, office supplies, toys, etc.

Applied Machines:

Mask machines, sealing machine, welding machines, cutting machines, Medical scalpel and tar clear.

1. Strong construction and highly efficient

2. Long life

3. Maximum sound output as a result of ideal oscillation characteristics

4. Short process times and very high process reliability

5. Metal converter protective housing

6. With Retaining ring (clamping ring)

7. Optional cooling air connections

8. Converter also available for rotary applications

Dukane 41S30 Replacement

Branson 402 Replacement

Branson 4TH Replacement

Branson 803 Replacement

Branson CJ20 Replacement

Dukane 110-3122 Replacement

20K Rinco With Booster Replacement

35K Telsonic Replacement

The ultrasonic transducer is mainly composed of a central piezoelectric ceramic element, front and rear metal covers, pre-stressed screws, electrode pads and insulating tubes. The specific composition is shown in the figure below.

The ultrasonic transducer is mainly composed of a central piezoelectric ceramic element, front and rear metal covers, pre-stressed screws, electrode pads and insulating tubes. The specific composition is shown in the figure below.

Back driver: The thick cylindrical element at the back of the piezoelectric transducer. The back driver abuts the rear-most ceramic and applies preload pressure, typically via a stacking bolt.

Electrodes: A thin electrically conductive disk placed between adjacent piezoelectric ceramics of a transducer. The transducer driving voltage is applied between these electrodes.

Front driver: Transmitting the transducer's ultrasonic energy to the horn or tool head, the front driver usually includes a mounting flange for connecting the housing.

Stack bolt: The bolt(s) used to sandwich the ceramics between the front and back drivers, thereby forming a resonant unit. When the bolt is tightened, it applies a compressive prestress to the ceramics.

Piezoelectric ceramic:Piezoelectric ceramics are the heart of the transducer. A component that converts the electrical signal of an ultrasonic generator into linear mechanical vibration.

Model | 35K Telsonic Replacement |

Frequency | 35Khz |

Output power | 1200Watt |

Joint bolt | M8*1.25 |

Ceramic disc Diameter | 25mm |

Quantity of Ceramic discs | 4pcs |

Capacitance | 4nF |

Application | Welding machine |

Ultrasonic transducer,ultrasonic generator and ultrasonic horn constitute a whole ultrasonic system, which can be widely used to do welding in various kinds of industries.

Applied Industries:

Automobile industry, electric industry, medical industry, household appliance industry,

non-woven fabric, clothing, packing, office supplies, toys, etc.

Applied Machines:

Mask machines, sealing machine, welding machines, cutting machines, Medical scalpel and tar clear.

1. Strong construction and highly efficient

2. Long life

3. Maximum sound output as a result of ideal oscillation characteristics

4. Short process times and very high process reliability

5. Metal converter protective housing

6. With Retaining ring (clamping ring)

7. Optional cooling air connections

8. Converter also available for rotary applications

Dukane 41S30 Replacement

Branson 402 Replacement

Branson 4TH Replacement

Branson 803 Replacement

Branson CJ20 Replacement

Dukane 110-3122 Replacement

20K Rinco With Booster Replacement

35K Telsonic Replacement

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.