| Availability: | |

|---|---|

| Quantity: | |

Branson 902J Replacement

SP

8543709990

The transducer, also called a converter, converts electrical energy from a generator into mechanical vibrations for the welding process. It consists of a number of piezoelectric ceramic discs sandwiched between two metal blocks (usually titanium).

Between each disc is a thin metal plate that forms the electrodes. When a sinusoidal electrical signal is fed to the converter through the electrodes, the disk expands and contracts, resulting in an axial peak-to-peak movement of 15 to 20 µm.

Converter are precision devices and should be handled with care. Once the element is damaged, the transducer will not work.

|  |  |

Branson 902J converter replacement for 910IW or IW+ systems.

902J converter for use with all Branson® 20 kHz 905 or 910D/M welders.

Model | Branson 902J Replacement |

Frequency | 20Khz |

Output power | 1000Watt |

Joint bolt | 1/2-20UNF |

Ceramic disc Diameter | 50mm |

Quantity of Ceramic discs | 4pcs |

Capacitance | 8nF |

Application | Welding machine |

Ultrasonic transducer,ultrasonic generator and ultrasonic horn constitute a whole

ultrasonic system, which can be widely used to do welding in various kinds of industries.

Automobile industry, electric industry, medical industry, household appliance industry,

non-woven fabric, clothing, packing, office supplies, toys, etc.

Mask machines, sealing machine, welding machines, cutting machines, Medical scalpel and tar clear.

1. Low resonance impedance

2. High mechanical Q value

3. High electroacoustic conversion efficiency

4. Good stability, low heat

5. Good consistency of frequency and static capacity

6. Provide customized service

7. One year warranty

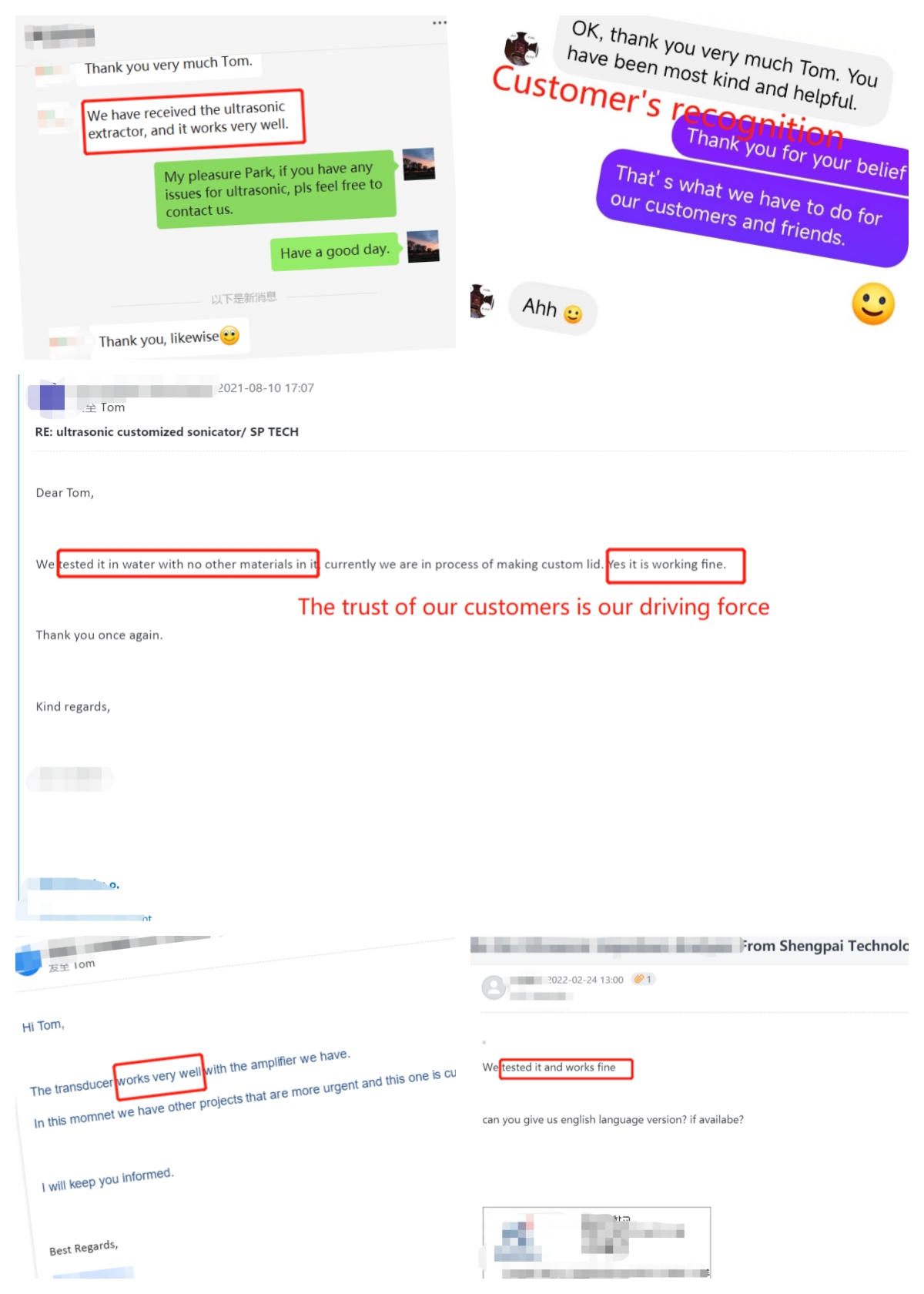

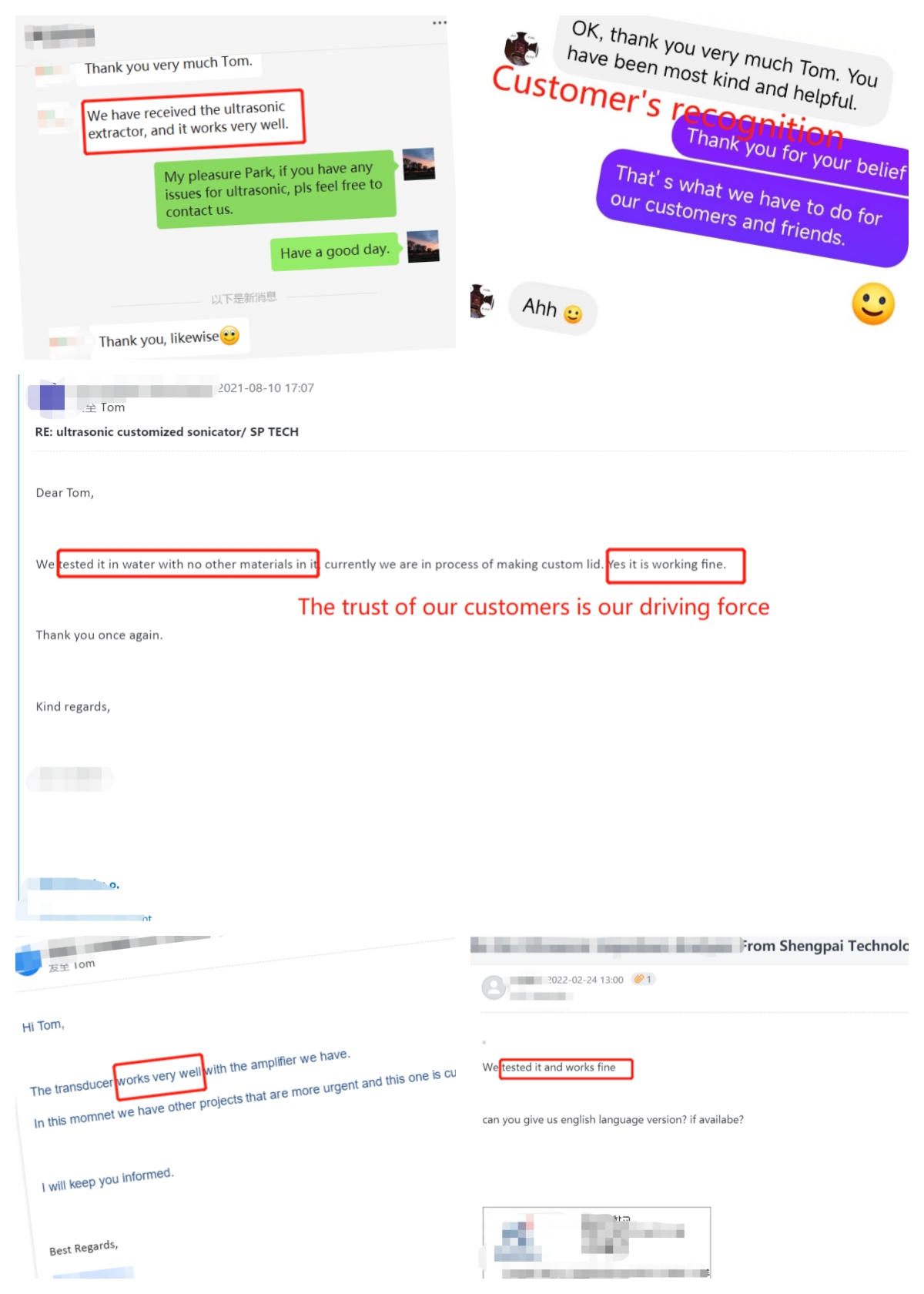

Customers' evalution as follow:

The ultrasonic transducer works very well.

The performance of welding equipment has been greatly improved.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

The transducer, also called a converter, converts electrical energy from a generator into mechanical vibrations for the welding process. It consists of a number of piezoelectric ceramic discs sandwiched between two metal blocks (usually titanium).

Between each disc is a thin metal plate that forms the electrodes. When a sinusoidal electrical signal is fed to the converter through the electrodes, the disk expands and contracts, resulting in an axial peak-to-peak movement of 15 to 20 µm.

Converter are precision devices and should be handled with care. Once the element is damaged, the transducer will not work.

|  |  |

Branson 902J converter replacement for 910IW or IW+ systems.

902J converter for use with all Branson® 20 kHz 905 or 910D/M welders.

Model | Branson 902J Replacement |

Frequency | 20Khz |

Output power | 1000Watt |

Joint bolt | 1/2-20UNF |

Ceramic disc Diameter | 50mm |

Quantity of Ceramic discs | 4pcs |

Capacitance | 8nF |

Application | Welding machine |

Ultrasonic transducer,ultrasonic generator and ultrasonic horn constitute a whole

ultrasonic system, which can be widely used to do welding in various kinds of industries.

Automobile industry, electric industry, medical industry, household appliance industry,

non-woven fabric, clothing, packing, office supplies, toys, etc.

Mask machines, sealing machine, welding machines, cutting machines, Medical scalpel and tar clear.

1. Low resonance impedance

2. High mechanical Q value

3. High electroacoustic conversion efficiency

4. Good stability, low heat

5. Good consistency of frequency and static capacity

6. Provide customized service

7. One year warranty

Customers' evalution as follow:

The ultrasonic transducer works very well.

The performance of welding equipment has been greatly improved.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.