| Availability: | |

|---|---|

| Quantity: | |

SP-2528-2Z

SP

8543709990

Description:

Description: An ultrasonic transducer is a device that converts electrical energy into high frequency sound waves, typically above the range of human hearing (20 kHz and above). The sound waves produced by an ultrasonic transducer can be used for various applications such as sensing, measuring, cleaning, welding, and more.

An ultrasonic transducer typically consists of one or more piezoelectric elements, which convert the electrical energy into mechanical vibrations that generate sound waves. When an electrical signal is applied to the piezoelectric element, it expands and contracts at the frequency of the signal, producing sound waves that propagate through a medium, such as air or water.

Specifications:

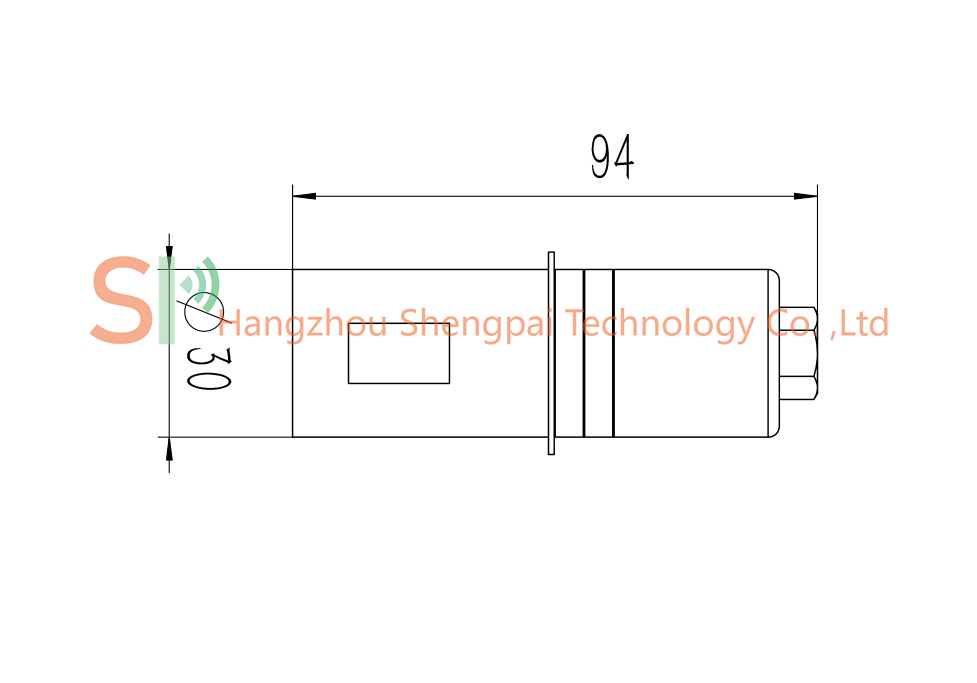

Model | SP-2528-2Z |

| Frequency | 28KHz |

| Output power | 300Watt |

| Joint bolt | M8*1 |

| Ceramic disc Diameter | 25mm |

| Quantity of Ceramic discs | 2pcs |

| Capacitance | 1.95~2.25nF, 2.3~2.5nF |

| Amplitude | 3um |

| Application | Spot Welding Machine |

Ultrasonic transducers are widely used in industrial, medical, and consumer applications. In industrial applications, ultrasonic transducers are used for sensing, measuring, and testing, as well as for cleaning and welding materials. In medical applications, ultrasonic transducers are used for imaging, diagnosis, and therapy. In consumer applications, ultrasonic transducers are used for cleaning and humidification.

The design and characteristics of ultrasonic transducers vary depending on the intended application. Some of the factors that influence the design of an ultrasonic transducer include the frequency, power, size, and shape of the transducer, as well as the medium in which it operates.

Ultrasonic transducers operating at 28KHz frequency can be used in the manufacturing of tea bags to seal the filter paper. The transducer generates high-frequency vibrations that produce heat, which melts the filter paper and fuses it together to form a strong, airtight seal.

Here are some of the advantages of using 28KHz ultrasonic transducers for tea bag manufacturing:

1. High Production Speed: Ultrasonic transducers can seal tea bags at a high speed, making them ideal for mass production.

2. Improved Product Quality: Ultrasonic sealing creates a strong, airtight seal that ensures the tea bags are of high quality and free from leaks.

3. Cost-Effective: Ultrasonic sealing is a cost-effective method compared to traditional sealing methods.

4. Energy-Efficient: Ultrasonic transducers consume less energy compared to other sealing methods.

5. Safe: Ultrasonic sealing is a safe and non-toxic method, making it ideal for the food industry.

Overall, 28KHz ultrasonic transducers are an ideal choice for sealing tea bags due to their high production speed, improved product quality, cost-effectiveness, energy efficiency, and safety.

Description:

Description: An ultrasonic transducer is a device that converts electrical energy into high frequency sound waves, typically above the range of human hearing (20 kHz and above). The sound waves produced by an ultrasonic transducer can be used for various applications such as sensing, measuring, cleaning, welding, and more.

An ultrasonic transducer typically consists of one or more piezoelectric elements, which convert the electrical energy into mechanical vibrations that generate sound waves. When an electrical signal is applied to the piezoelectric element, it expands and contracts at the frequency of the signal, producing sound waves that propagate through a medium, such as air or water.

Specifications:

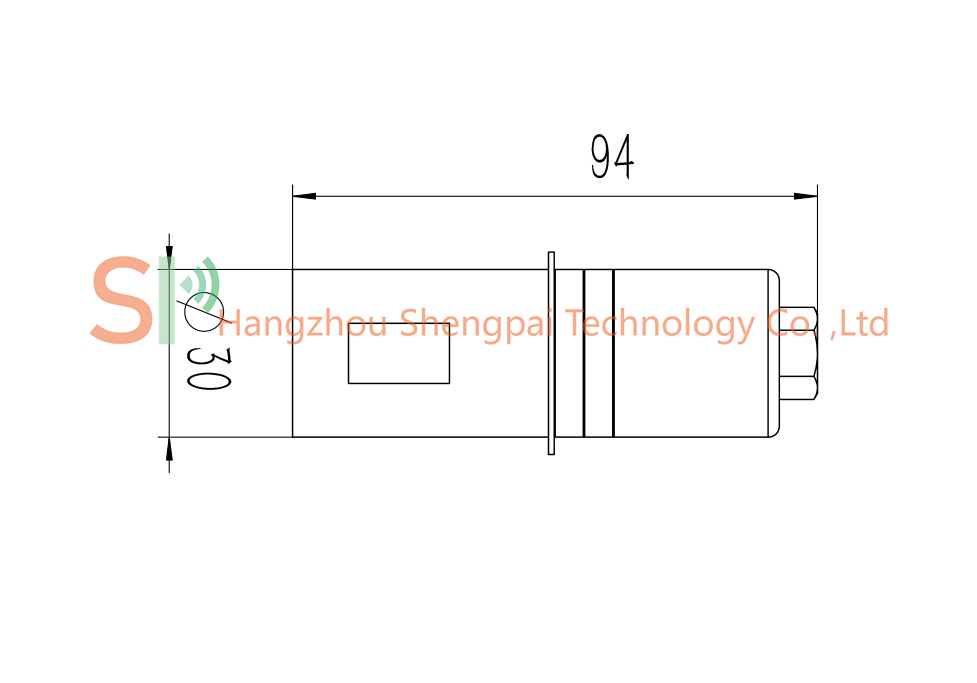

Model | SP-2528-2Z |

| Frequency | 28KHz |

| Output power | 300Watt |

| Joint bolt | M8*1 |

| Ceramic disc Diameter | 25mm |

| Quantity of Ceramic discs | 2pcs |

| Capacitance | 1.95~2.25nF, 2.3~2.5nF |

| Amplitude | 3um |

| Application | Spot Welding Machine |

Ultrasonic transducers are widely used in industrial, medical, and consumer applications. In industrial applications, ultrasonic transducers are used for sensing, measuring, and testing, as well as for cleaning and welding materials. In medical applications, ultrasonic transducers are used for imaging, diagnosis, and therapy. In consumer applications, ultrasonic transducers are used for cleaning and humidification.

The design and characteristics of ultrasonic transducers vary depending on the intended application. Some of the factors that influence the design of an ultrasonic transducer include the frequency, power, size, and shape of the transducer, as well as the medium in which it operates.

Ultrasonic transducers operating at 28KHz frequency can be used in the manufacturing of tea bags to seal the filter paper. The transducer generates high-frequency vibrations that produce heat, which melts the filter paper and fuses it together to form a strong, airtight seal.

Here are some of the advantages of using 28KHz ultrasonic transducers for tea bag manufacturing:

1. High Production Speed: Ultrasonic transducers can seal tea bags at a high speed, making them ideal for mass production.

2. Improved Product Quality: Ultrasonic sealing creates a strong, airtight seal that ensures the tea bags are of high quality and free from leaks.

3. Cost-Effective: Ultrasonic sealing is a cost-effective method compared to traditional sealing methods.

4. Energy-Efficient: Ultrasonic transducers consume less energy compared to other sealing methods.

5. Safe: Ultrasonic sealing is a safe and non-toxic method, making it ideal for the food industry.

Overall, 28KHz ultrasonic transducers are an ideal choice for sealing tea bags due to their high production speed, improved product quality, cost-effectiveness, energy efficiency, and safety.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.