| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

In the rapidly advancing landscape of technological innovations, the ultrasonic homogenizer shines as a beacon of progress, revolutionizing essential homogenization processes that underpin a multitude of industries. As various sectors continue to seek meticulous control over material characteristics, the ultrasonic homogenizer emerges as an unwavering and efficient solution. This comprehensive article embarks on an in-depth exploration of the intricate workings of the ultrasonic homogenizer, unraveling its fundamental principles, dissecting its complex components, unveiling its diverse applications, and highlighting the myriad advantages it bestows upon industries.

Homogenization, the process of achieving uniformity in composition, texture, or particle size within a substance, stands as a cornerstone across industries. Whether it's in the pharmaceutical realm, where precise drug distribution is paramount, or the food industry, where consistent flavors and textures define excellence, homogenization drives product quality and performance. Amidst this critical backdrop, the ultrasonic homogenizer, characterized by its employment of ultrasonic waves, emerges as a powerful instrument, operating at frequencies beyond human auditory perception, and enabling the disruption of particles and cell structures within diverse materials.

Ultrasonic homogenizer through ultrasonic cavitation reaction to achieve ultrasonic dispersion, emulsification, crushing and other tasks. The vibration of the tool head of the ultrasonic homogenizer is very rapid, causing bubbles in the surrounding solution to form and collapse rapidly, tearing cells and particles.Ultrasound is now widely used in industrial production, including making emulsions, dispersing nanoparticles and reducing the size of particles in suspension.

Ultrasonic homogenizer through ultrasonic cavitation reaction to achieve ultrasonic dispersion, emulsification, crushing and other tasks. The vibration of the tool head of the ultrasonic homogenizer is very rapid, causing bubbles in the surrounding solution to form and collapse rapidly, tearing cells and particles.Ultrasound is now widely used in industrial production, including making emulsions, dispersing nanoparticles and reducing the size of particles in suspension. Ultrasonic homogenizers, sometimes called sonicators or sonifiers, destroy tissue and cells through cavitation and ultrasound.

They consist of three parts:

A generator that provides and controls the power

A transducer (also known as a converter) containing a piezoelectric crystal that converts electrical energy into mechanical motion at very high frequency.The converter also amplifies the signal.

The titanium probe or "horn" vibrates rapidly along the longitudinal direction to transmit ultrasonic energy to the sample.

Homogenization occurs both directly through ultrasonic forces and through cavitation (the rapid formation and rupture of bubbles).

The combination of these forces makes ultrasonic homogenizers ideal for cell rupture and particle size reduction.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

1. High yields

2. Superior Quality

3. Full Spectrum Extracts

4. Rapid Process

5. Compatible with Any Solvent

6. Easy and Safe to Operate

7. Linear Scalability

8. Environmental-Friendly

9. Fast RoI

1. Core parts with Titanium materials

2. Ultrasonic horn(probe) with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability, long working hours, radiation area is increased 2.5 times than traditional tools

7. High amplitude to let ultrasonic cavitation strength to process liquids more efficiency

8. Provide consulting services and custom reactor designs

9. Custom sizes available for laboratory and high volume industrial applications

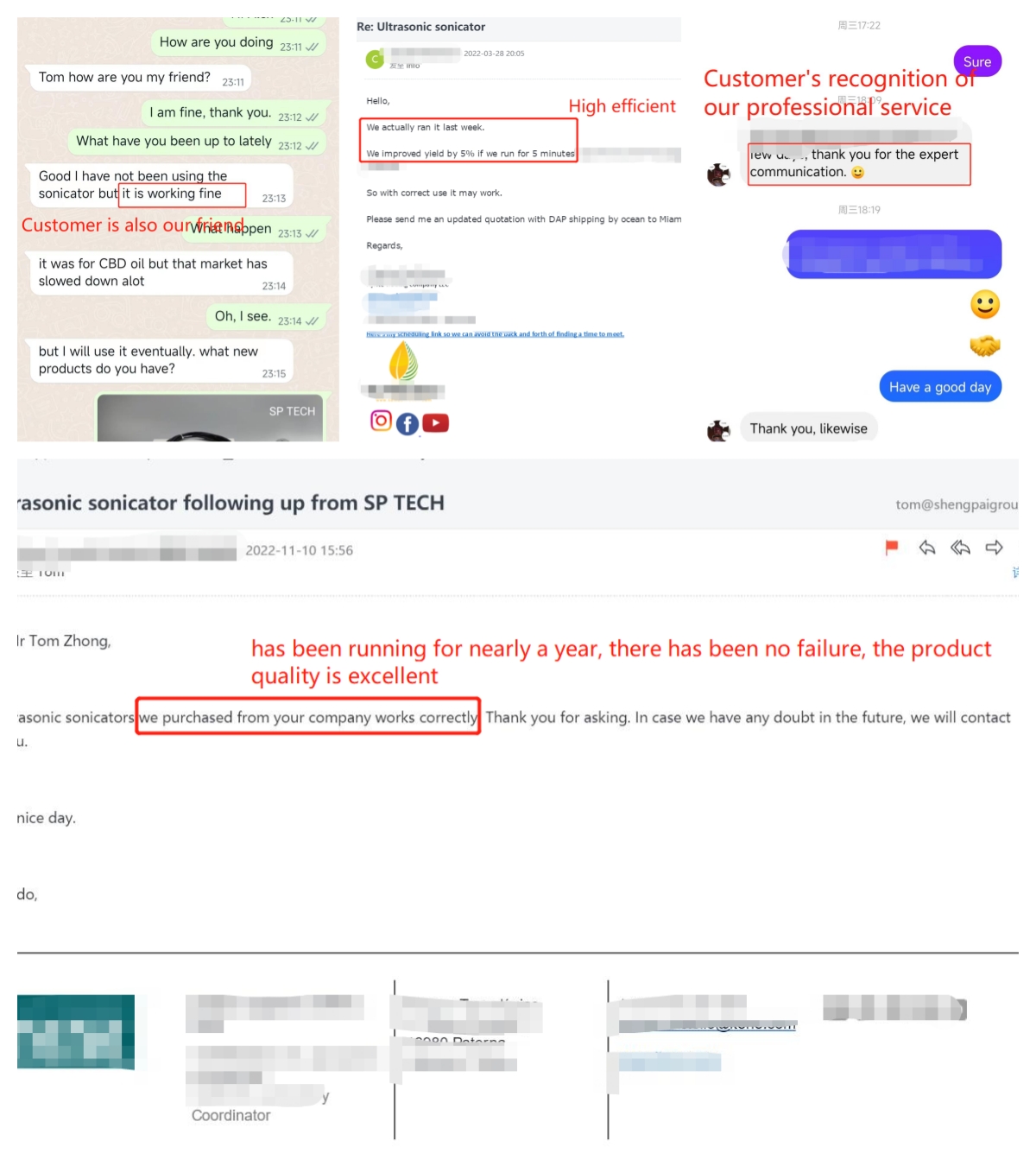

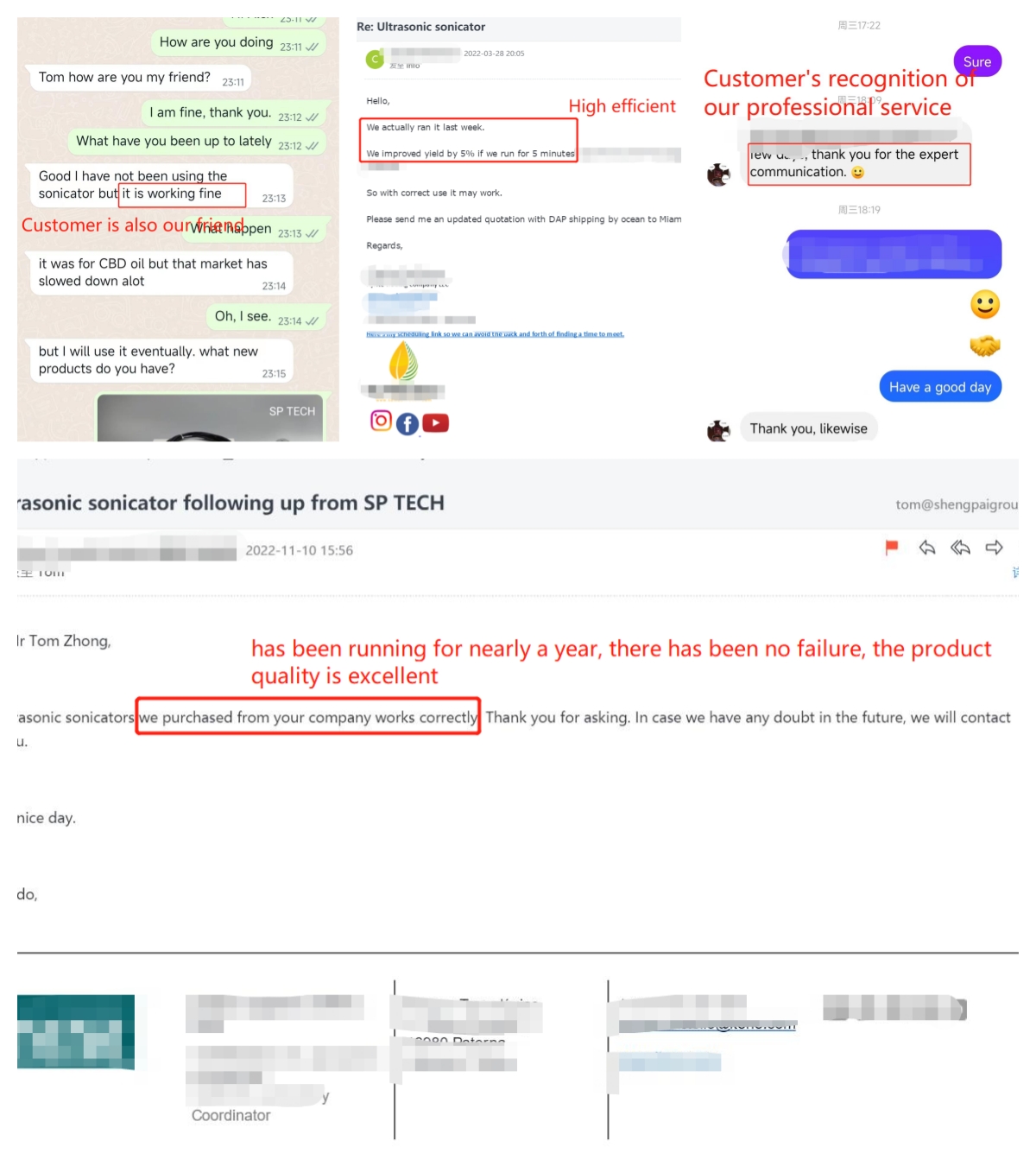

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. How does ultrasonic extraction enhance the efficiency of CBD extraction?

Ultrasonic extraction utilizes high-frequency vibrations to break down plant cell walls, allowing for better release of CBD compounds, resulting in higher extraction efficiency.

2. Can the Liquid Processor be customized for specific CBD strains and target compounds?

Yes, the Liquid Processor offers precise control over extraction parameters, allowing customization for different CBD strains and target compounds.

3. What are the advantages of ultrasonic extraction over traditional methods?

Ultrasonic extraction offers higher extraction yields, improved quality of extracts, preservation of CBD integrity, and reduced extraction time compared to traditional methods.

4. How does the Liquid Processor preserve the integrity of CBD compounds during extraction?

The Liquid Processor's gentle yet powerful ultrasonic waves ensure minimal degradation of CBD compounds, preserving their potency and therapeutic properties during extraction.

5. Is the Liquid Processor suitable for both small-scale and large-scale production?

Yes, the Liquid Processor is available in various sizes and capacities, making it suitable for both small-scale laboratory research and large-scale industrial production.

6. Can the Liquid Processor be used for research purposes in laboratories?

Absolutely, the Liquid Processor is widely used in laboratory research for exploring innovative extraction techniques and optimizing CBD extraction parameters.

7. What industries can benefit from the Ultrasonic Liquid Processor?

The Ultrasonic Liquid Processor is beneficial for industries such as pharmaceuticals, nutraceuticals, CBD product manufacturing, cosmeceuticals, and the cannabis industry, among others.

8. Does the Liquid Processor offer pre-programmed settings for common extraction protocols?

Yes, the Liquid Processor features pre-programmed settings for common extraction protocols, ensuring ease of use and saving valuable time.

9. Can the Liquid Processor be used for the extraction of CBD from plants?

Absolutely, the Liquid Processor is highly effective in extracting CBD from plants, making it ideal for derived CBD products.

10. What are the warranty and after-sales support options provided with the Ultrasonic Liquid Processor?

We offer a comprehensive warranty for the Ultrasonic Liquid Processor, along with dedicated after-sales support to ensure customer satisfaction and optimal performance of the equipment.

In the rapidly advancing landscape of technological innovations, the ultrasonic homogenizer shines as a beacon of progress, revolutionizing essential homogenization processes that underpin a multitude of industries. As various sectors continue to seek meticulous control over material characteristics, the ultrasonic homogenizer emerges as an unwavering and efficient solution. This comprehensive article embarks on an in-depth exploration of the intricate workings of the ultrasonic homogenizer, unraveling its fundamental principles, dissecting its complex components, unveiling its diverse applications, and highlighting the myriad advantages it bestows upon industries.

Homogenization, the process of achieving uniformity in composition, texture, or particle size within a substance, stands as a cornerstone across industries. Whether it's in the pharmaceutical realm, where precise drug distribution is paramount, or the food industry, where consistent flavors and textures define excellence, homogenization drives product quality and performance. Amidst this critical backdrop, the ultrasonic homogenizer, characterized by its employment of ultrasonic waves, emerges as a powerful instrument, operating at frequencies beyond human auditory perception, and enabling the disruption of particles and cell structures within diverse materials.

Ultrasonic homogenizer through ultrasonic cavitation reaction to achieve ultrasonic dispersion, emulsification, crushing and other tasks. The vibration of the tool head of the ultrasonic homogenizer is very rapid, causing bubbles in the surrounding solution to form and collapse rapidly, tearing cells and particles.Ultrasound is now widely used in industrial production, including making emulsions, dispersing nanoparticles and reducing the size of particles in suspension.

Ultrasonic homogenizer through ultrasonic cavitation reaction to achieve ultrasonic dispersion, emulsification, crushing and other tasks. The vibration of the tool head of the ultrasonic homogenizer is very rapid, causing bubbles in the surrounding solution to form and collapse rapidly, tearing cells and particles.Ultrasound is now widely used in industrial production, including making emulsions, dispersing nanoparticles and reducing the size of particles in suspension. Ultrasonic homogenizers, sometimes called sonicators or sonifiers, destroy tissue and cells through cavitation and ultrasound.

They consist of three parts:

A generator that provides and controls the power

A transducer (also known as a converter) containing a piezoelectric crystal that converts electrical energy into mechanical motion at very high frequency.The converter also amplifies the signal.

The titanium probe or "horn" vibrates rapidly along the longitudinal direction to transmit ultrasonic energy to the sample.

Homogenization occurs both directly through ultrasonic forces and through cavitation (the rapid formation and rupture of bubbles).

The combination of these forces makes ultrasonic homogenizers ideal for cell rupture and particle size reduction.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

1. High yields

2. Superior Quality

3. Full Spectrum Extracts

4. Rapid Process

5. Compatible with Any Solvent

6. Easy and Safe to Operate

7. Linear Scalability

8. Environmental-Friendly

9. Fast RoI

1. Core parts with Titanium materials

2. Ultrasonic horn(probe) with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability, long working hours, radiation area is increased 2.5 times than traditional tools

7. High amplitude to let ultrasonic cavitation strength to process liquids more efficiency

8. Provide consulting services and custom reactor designs

9. Custom sizes available for laboratory and high volume industrial applications

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. How does ultrasonic extraction enhance the efficiency of CBD extraction?

Ultrasonic extraction utilizes high-frequency vibrations to break down plant cell walls, allowing for better release of CBD compounds, resulting in higher extraction efficiency.

2. Can the Liquid Processor be customized for specific CBD strains and target compounds?

Yes, the Liquid Processor offers precise control over extraction parameters, allowing customization for different CBD strains and target compounds.

3. What are the advantages of ultrasonic extraction over traditional methods?

Ultrasonic extraction offers higher extraction yields, improved quality of extracts, preservation of CBD integrity, and reduced extraction time compared to traditional methods.

4. How does the Liquid Processor preserve the integrity of CBD compounds during extraction?

The Liquid Processor's gentle yet powerful ultrasonic waves ensure minimal degradation of CBD compounds, preserving their potency and therapeutic properties during extraction.

5. Is the Liquid Processor suitable for both small-scale and large-scale production?

Yes, the Liquid Processor is available in various sizes and capacities, making it suitable for both small-scale laboratory research and large-scale industrial production.

6. Can the Liquid Processor be used for research purposes in laboratories?

Absolutely, the Liquid Processor is widely used in laboratory research for exploring innovative extraction techniques and optimizing CBD extraction parameters.

7. What industries can benefit from the Ultrasonic Liquid Processor?

The Ultrasonic Liquid Processor is beneficial for industries such as pharmaceuticals, nutraceuticals, CBD product manufacturing, cosmeceuticals, and the cannabis industry, among others.

8. Does the Liquid Processor offer pre-programmed settings for common extraction protocols?

Yes, the Liquid Processor features pre-programmed settings for common extraction protocols, ensuring ease of use and saving valuable time.

9. Can the Liquid Processor be used for the extraction of CBD from plants?

Absolutely, the Liquid Processor is highly effective in extracting CBD from plants, making it ideal for derived CBD products.

10. What are the warranty and after-sales support options provided with the Ultrasonic Liquid Processor?

We offer a comprehensive warranty for the Ultrasonic Liquid Processor, along with dedicated after-sales support to ensure customer satisfaction and optimal performance of the equipment.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.