| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000S

SP

8543709990

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples.

Ultrasonic extraction uses ultrasonic extraction machine to increase the molecular motion frequency of substances by using the strong cavitation effect, mechanical vibration, disturbance effect, high acceleration, emulsification, diffusion, crushing and stirring effects generated by ultrasonic radiation pressure. And speed, increasing the solvent penetration, thereby accelerating the target component into the solvent and facilitating the extraction of the mature extraction technique. Ultrasonic extraction technology is applicable to a wide range of extracting agents. Water, methanol, ethanol and the like are commonly used extracting agents, which have the advantages of simple operation and high extraction efficiency.

This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

iciency.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

This technology provides a method forultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

1. Homogenization – making uniform mixtures of liquids or liquid suspensions.

2. Emulsification – processing foods, pharmaceuticals, and cosmetics.

3. Dissolution – dissolving solids in solvents.

4. Degassing – removing gases from solutions without heat or vacuum.

3. Inline pipe cleaning, removes scale or build/up without disassembly.

4. Cylindrical 360°internally radiating chamber.

5. Internal or external liquid atomizing or powder making sonotrode.

1.Ultrasonic extraction can achieve higher extraction yields in a shorter time compared to traditional extraction methods such as maceration and Soxhlet extraction.

2.Ultrasonic extraction can extract compounds within minutes to a few hours, which is much faster than traditional extraction methods that may take several days or even weeks.

3.Ultrasonic extraction can be used to extract specific compounds by adjusting the frequency, power, and duration of the sound waves. This makes it possible to selectively extract the target compounds without extracting unwanted compounds.

4.Ultrasonic extraction uses only water or other solvents, eliminating the need for toxic solvents that are harmful to the environment and human health. This makes it a green and eco-friendly extraction technique.

5.Ultrasonic extraction is easy to scale up from laboratory to industrial production. The same equipment can be used for small-scale and large-scale production, which makes it a cost-effective extraction technique.

6.Ultrasonic extraction can extract high-quality compounds with a higher purity and better bioactivity compared to traditional extraction methods.

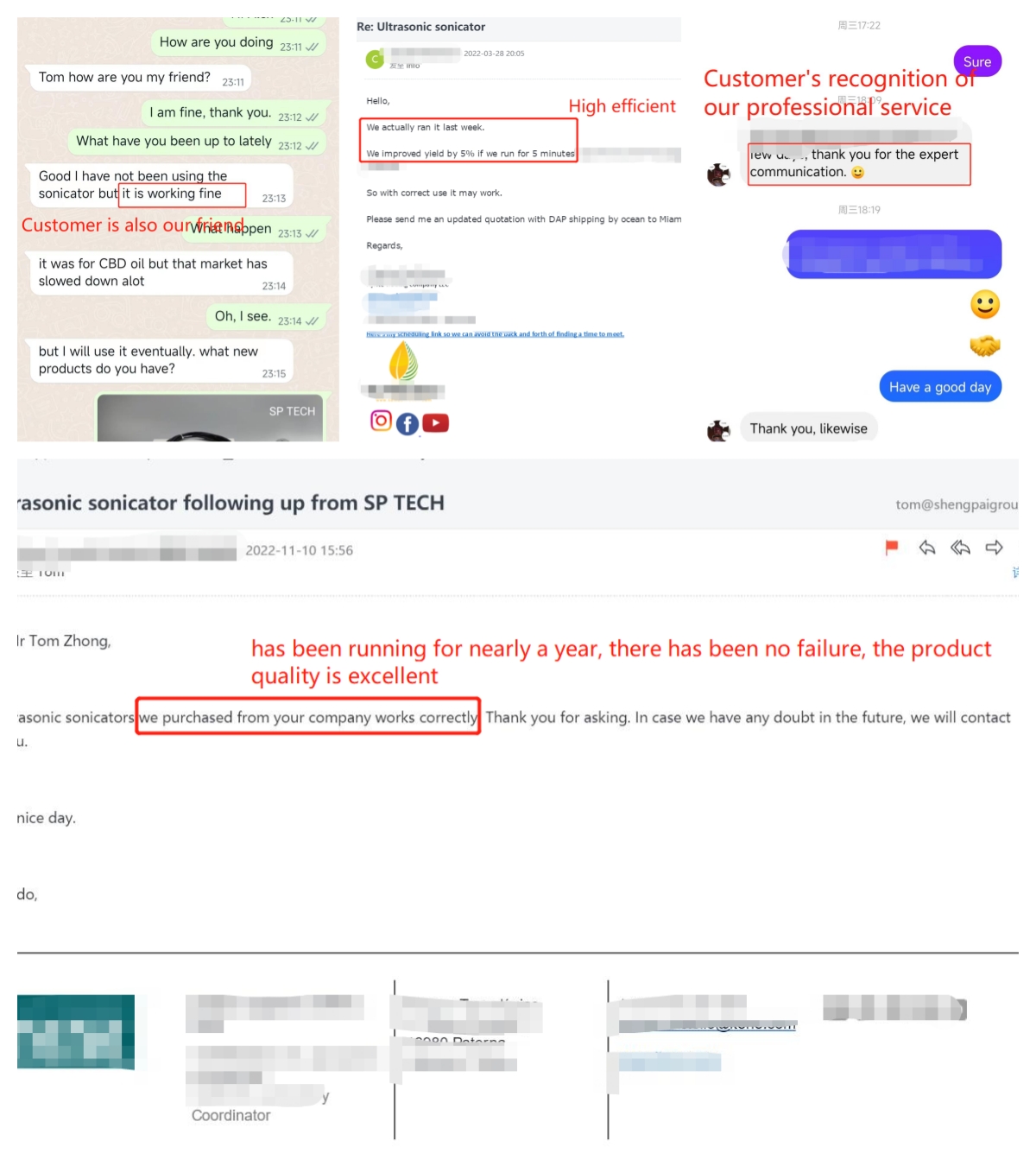

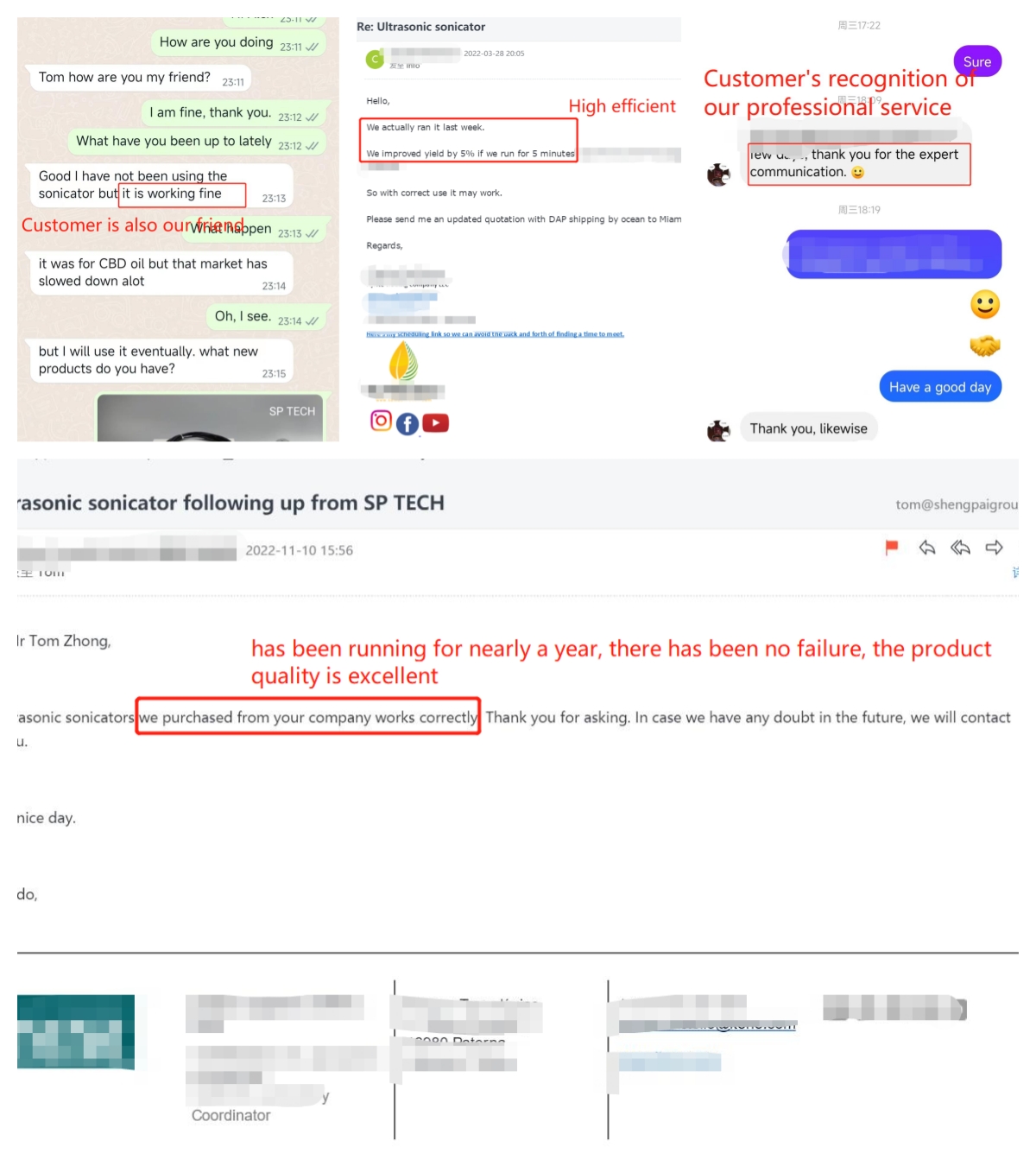

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples.

Ultrasonic extraction uses ultrasonic extraction machine to increase the molecular motion frequency of substances by using the strong cavitation effect, mechanical vibration, disturbance effect, high acceleration, emulsification, diffusion, crushing and stirring effects generated by ultrasonic radiation pressure. And speed, increasing the solvent penetration, thereby accelerating the target component into the solvent and facilitating the extraction of the mature extraction technique. Ultrasonic extraction technology is applicable to a wide range of extracting agents. Water, methanol, ethanol and the like are commonly used extracting agents, which have the advantages of simple operation and high extraction efficiency.

This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

iciency.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

This technology provides a method forultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

1. Homogenization – making uniform mixtures of liquids or liquid suspensions.

2. Emulsification – processing foods, pharmaceuticals, and cosmetics.

3. Dissolution – dissolving solids in solvents.

4. Degassing – removing gases from solutions without heat or vacuum.

3. Inline pipe cleaning, removes scale or build/up without disassembly.

4. Cylindrical 360°internally radiating chamber.

5. Internal or external liquid atomizing or powder making sonotrode.

1.Ultrasonic extraction can achieve higher extraction yields in a shorter time compared to traditional extraction methods such as maceration and Soxhlet extraction.

2.Ultrasonic extraction can extract compounds within minutes to a few hours, which is much faster than traditional extraction methods that may take several days or even weeks.

3.Ultrasonic extraction can be used to extract specific compounds by adjusting the frequency, power, and duration of the sound waves. This makes it possible to selectively extract the target compounds without extracting unwanted compounds.

4.Ultrasonic extraction uses only water or other solvents, eliminating the need for toxic solvents that are harmful to the environment and human health. This makes it a green and eco-friendly extraction technique.

5.Ultrasonic extraction is easy to scale up from laboratory to industrial production. The same equipment can be used for small-scale and large-scale production, which makes it a cost-effective extraction technique.

6.Ultrasonic extraction can extract high-quality compounds with a higher purity and better bioactivity compared to traditional extraction methods.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.