| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000S

SP

8543709990

The ultrasonic liquid processor employs the fascinating phenomenon of ultrasonic cavitation to effectively disperse agglomerated particles within a liquid medium. This cutting-edge technology harnesses the power of ultrasonic waves, inducing a "cavitation" effect that triggers localized high temperatures, elevated pressure zones, robust shockwaves, and micro jets. These dynamic forces propagate through the liquid in the form of standing waves within the suspended body, creating a series of actions that play a crucial role in particle dispersion.

As the ultrasonic waves traverse the liquid, they cause the particles to undergo periodic stretching and compression. This rhythmic oscillation exerts substantial mechanical forces on the agglomerated structure, leading to its gradual disintegration. The combination of high temperature, pressure variations, shockwaves, and micro jets contributes to the breakdown of inter-particle bonds, effectively dismantling the agglomerates.5.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy

|

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1Energy Efficiency: One of the notable advantages of ultrasonic liquid processing lies in its energy efficiency. Unlike traditional mixing and ball milling processes, ultrasonic technology typically requires lower energy consumption, contributing to cost savings and making it an environmentally friendly choice.

2.Enhanced Scalability: The ultrasonic liquid processor is highly scalable, making it particularly well-suited for industrial production settings. Its ability to handle larger volumes without a proportional increase in operation costs adds to its economic appeal for manufacturing applications.

3.Controlled Chemical Reactions: In the case of liquid-liquid mixtures, the ultrasonic liquid processor accelerates chemical reactions, enabling faster reaction speeds. This not only improves the efficiency of the production process but also allows for a reduction in the amount of additives required. The controlled environment created by ultrasonic processing ensures a fully mixed solution that remains stable over time, minimizing the risk of stratification.

4.Rapid Dispersion of Agglomerated Nanoparticles: When dealing with solid-liquid mixtures, the ultrasonic liquid processor excels at quickly breaking down agglomerated nanoparticles. This rapid dispersion ensures that ultrafine particles remain separated, preventing re-agglomeration. The ability to efficiently address agglomeration challenges is a crucial advantage, particularly in industries where maintaining a consistent and finely dispersed particle size is essential for product quality.

5.Versatility in Material Processing: The ultrasonic liquid processor showcases versatility in handling a wide range of materials. Whether dealing with liquids, solids, or a combination of both, its adaptability makes it a valuable tool in diverse industries such as pharmaceuticals, cosmetics, and nanotechnology. This versatility extends its utility beyond specific applications, offering a broad spectrum of processing capabilities for various materials and formulations.

1.Graphene Dispersion:

Ultrasonic liquid processors are instrumental in achieving uniform dispersion of graphene, The technology ensures effective separation of graphene sheets, preventing agglomeration and enhancing the overall performance of graphene-based materials in various applications such as electronics, composites, and energy storage devices.

2.Silica Dispersion:

Silica dispersion is critical in industries ranging from pharmaceuticals to coatings. Ultrasonic liquid processors excel in efficiently dispersing silica nanoparticles, enhancing the properties of silica-based materials. This application finds relevance in developing advanced materials with improved strength, wear resistance, and optical characteristics.

3.Paint Dispersion:

The efficient dispersion of pigments and additives in paint formulations is essential for achieving consistent color, texture, and performance. Ultrasonic liquid processors play a key role in breaking down pigment agglomerates, resulting in a finely dispersed paint mixture. This technology contributes to the production of high-quality paints with improved coverage and durability.

4.Alumina Dispersion:

Alumina dispersion is crucial in applications where alumina nanoparticles are employed, such as in ceramics, catalysts, and electronic components. Ultrasonic liquid processors facilitate the rapid dispersion of alumina particles, preventing clumping and ensuring a homogeneous mixture. This contributes to the enhanced properties of alumina-based materials in terms of strength, thermal conductivity, and corrosion resistance.

5.Lithium Battery Slurry:

The preparation of a uniform slurry is a key step in the manufacturing of lithium-ion batteries. Ultrasonic liquid processors aid in achieving a well-dispersed lithium battery slurry, improving the electrode's performance.

6.Nano Materials:

Ultrasonic liquid processors find widespread application in handling various nano materials.

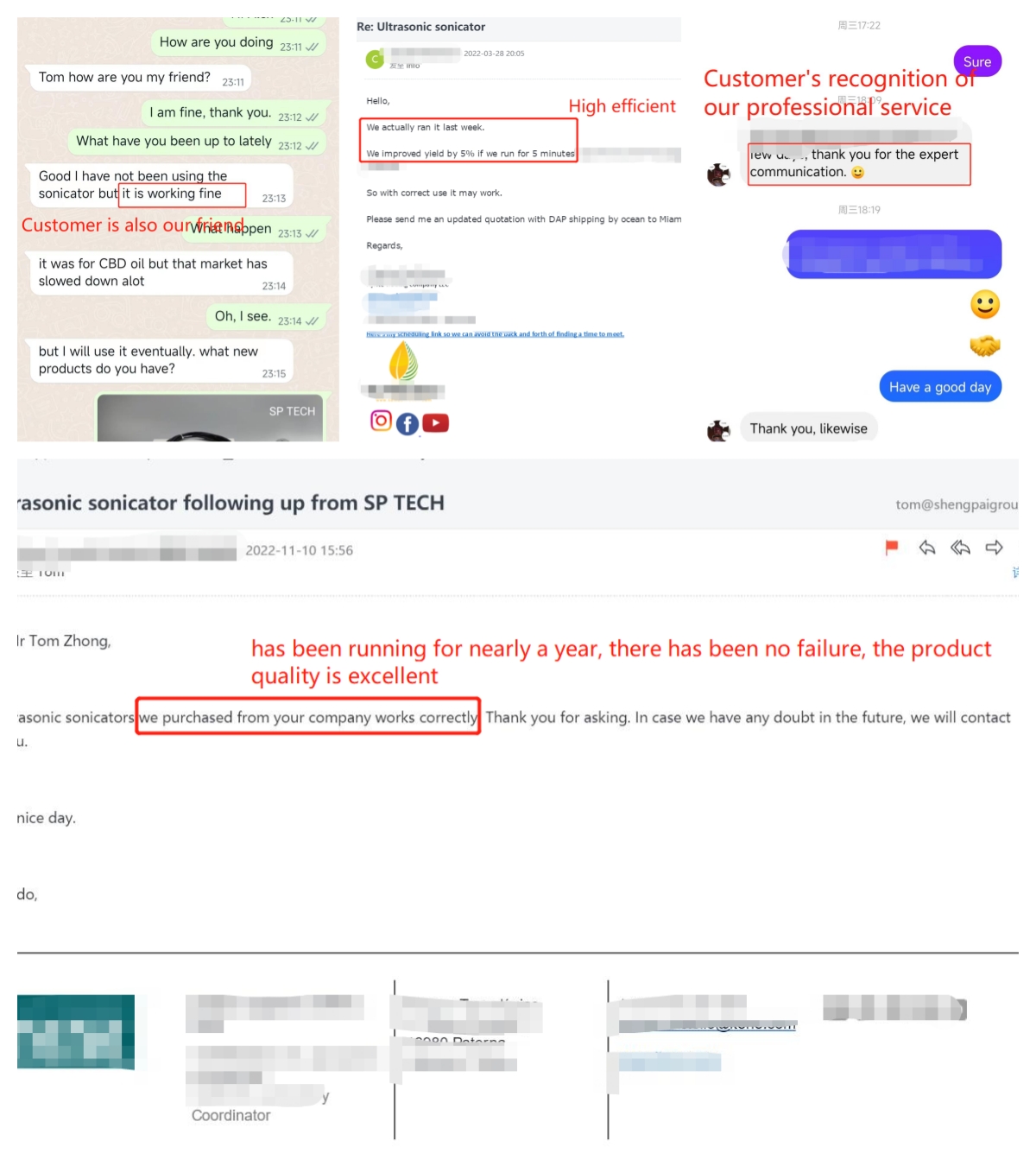

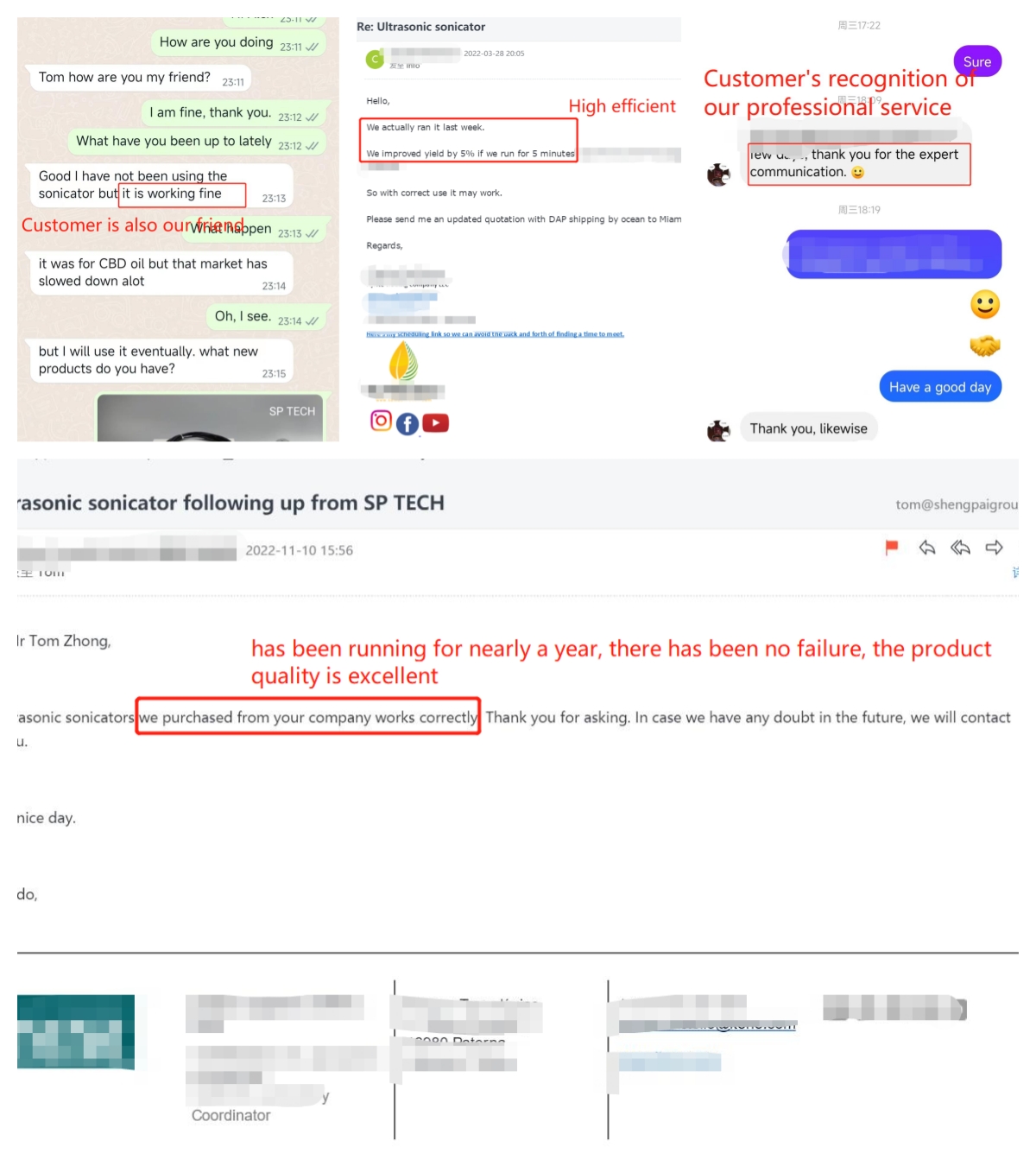

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. Do you have it in stock?

We only have common products in stock but not for the nonstandard products.Because all the products need make based on customers' different requirements.

2. Could you advise to us the design based on our special requirements or based on our object samples?

Of course, we can do. Please tell us your idea or your application.

If you have sample object, send it to us or send detail pictures.

3.How long do you make the order product?

Common products for 7days, big qty and none standard products for 20days.

4. Do you have operating manual?

Of course, we will put it with the goods together.

5. How about the quality?

We have export to many other customers from all over the world, the feed back is good,quality is the first of our company.

6. Could you do OEM?

Yes, of course. We can produce according customers' requirement, just send us your requirements and design of drawing and sample.

7. Could we as your agent?

Of course. We are looking for sole agent in Country who have the willing to cooperate with us for long business term.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

The ultrasonic liquid processor employs the fascinating phenomenon of ultrasonic cavitation to effectively disperse agglomerated particles within a liquid medium. This cutting-edge technology harnesses the power of ultrasonic waves, inducing a "cavitation" effect that triggers localized high temperatures, elevated pressure zones, robust shockwaves, and micro jets. These dynamic forces propagate through the liquid in the form of standing waves within the suspended body, creating a series of actions that play a crucial role in particle dispersion.

As the ultrasonic waves traverse the liquid, they cause the particles to undergo periodic stretching and compression. This rhythmic oscillation exerts substantial mechanical forces on the agglomerated structure, leading to its gradual disintegration. The combination of high temperature, pressure variations, shockwaves, and micro jets contributes to the breakdown of inter-particle bonds, effectively dismantling the agglomerates.5.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy

|

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1Energy Efficiency: One of the notable advantages of ultrasonic liquid processing lies in its energy efficiency. Unlike traditional mixing and ball milling processes, ultrasonic technology typically requires lower energy consumption, contributing to cost savings and making it an environmentally friendly choice.

2.Enhanced Scalability: The ultrasonic liquid processor is highly scalable, making it particularly well-suited for industrial production settings. Its ability to handle larger volumes without a proportional increase in operation costs adds to its economic appeal for manufacturing applications.

3.Controlled Chemical Reactions: In the case of liquid-liquid mixtures, the ultrasonic liquid processor accelerates chemical reactions, enabling faster reaction speeds. This not only improves the efficiency of the production process but also allows for a reduction in the amount of additives required. The controlled environment created by ultrasonic processing ensures a fully mixed solution that remains stable over time, minimizing the risk of stratification.

4.Rapid Dispersion of Agglomerated Nanoparticles: When dealing with solid-liquid mixtures, the ultrasonic liquid processor excels at quickly breaking down agglomerated nanoparticles. This rapid dispersion ensures that ultrafine particles remain separated, preventing re-agglomeration. The ability to efficiently address agglomeration challenges is a crucial advantage, particularly in industries where maintaining a consistent and finely dispersed particle size is essential for product quality.

5.Versatility in Material Processing: The ultrasonic liquid processor showcases versatility in handling a wide range of materials. Whether dealing with liquids, solids, or a combination of both, its adaptability makes it a valuable tool in diverse industries such as pharmaceuticals, cosmetics, and nanotechnology. This versatility extends its utility beyond specific applications, offering a broad spectrum of processing capabilities for various materials and formulations.

1.Graphene Dispersion:

Ultrasonic liquid processors are instrumental in achieving uniform dispersion of graphene, The technology ensures effective separation of graphene sheets, preventing agglomeration and enhancing the overall performance of graphene-based materials in various applications such as electronics, composites, and energy storage devices.

2.Silica Dispersion:

Silica dispersion is critical in industries ranging from pharmaceuticals to coatings. Ultrasonic liquid processors excel in efficiently dispersing silica nanoparticles, enhancing the properties of silica-based materials. This application finds relevance in developing advanced materials with improved strength, wear resistance, and optical characteristics.

3.Paint Dispersion:

The efficient dispersion of pigments and additives in paint formulations is essential for achieving consistent color, texture, and performance. Ultrasonic liquid processors play a key role in breaking down pigment agglomerates, resulting in a finely dispersed paint mixture. This technology contributes to the production of high-quality paints with improved coverage and durability.

4.Alumina Dispersion:

Alumina dispersion is crucial in applications where alumina nanoparticles are employed, such as in ceramics, catalysts, and electronic components. Ultrasonic liquid processors facilitate the rapid dispersion of alumina particles, preventing clumping and ensuring a homogeneous mixture. This contributes to the enhanced properties of alumina-based materials in terms of strength, thermal conductivity, and corrosion resistance.

5.Lithium Battery Slurry:

The preparation of a uniform slurry is a key step in the manufacturing of lithium-ion batteries. Ultrasonic liquid processors aid in achieving a well-dispersed lithium battery slurry, improving the electrode's performance.

6.Nano Materials:

Ultrasonic liquid processors find widespread application in handling various nano materials.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. Do you have it in stock?

We only have common products in stock but not for the nonstandard products.Because all the products need make based on customers' different requirements.

2. Could you advise to us the design based on our special requirements or based on our object samples?

Of course, we can do. Please tell us your idea or your application.

If you have sample object, send it to us or send detail pictures.

3.How long do you make the order product?

Common products for 7days, big qty and none standard products for 20days.

4. Do you have operating manual?

Of course, we will put it with the goods together.

5. How about the quality?

We have export to many other customers from all over the world, the feed back is good,quality is the first of our company.

6. Could you do OEM?

Yes, of course. We can produce according customers' requirement, just send us your requirements and design of drawing and sample.

7. Could we as your agent?

Of course. We are looking for sole agent in Country who have the willing to cooperate with us for long business term.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.