| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000S

SP

8543709990

Ultrasonic disperser is a kind of dispersing means with high intensity and best effect by directly placing the particle suspension to be treated in the ultrasonic field and "irradiating" with high-power ultrasonic waves.

First of all, the propagation of ultrasound needs to be based on the medium.

The propagation of ultrasonic waves in the medium has an alternating cycle of positive and negative pressures. The medium is squeezed and pulled under the positive and negative pressure of the colloid.

When ultrasonic waves act on the medium liquid, the distance between the molecules in the negative pressure zone will exceed the critical molecular distance that the liquid medium remains unchanged. The liquid medium will break, forming micro bubbles, and the micro bubbles will become cavitation.

The bubble can be redissolved in the gas, it can also float up and disappear, or it may collapse from the resonance phase of the ultrasonic field. It produces local high temperature and high pressure, and produce huge impact force and micro jet. Under the action of nano particle, the surface energy can be weakened, thus achieving the dispersion of nano particle.

Item No. | Parameters | |

Type | SPS20-500S | SPS20-1000S |

Ultrasonic Power(W) | 500 | 1000 |

Cooling Power(W) | / | 200 |

Amplitude Range(um) | 0-50 | |

Processing Capacity(L/H) | 0.5-2.0 | 1.0-4.0 |

Constant Temperature Control(℃) | / | 10-75 |

Cavitation Intensity (w/cm2) | 0-5.0 | |

Reaction Device | Beaker | Reaction kettle/ Beaker |

Volume(ml) | 500 | 500-1000 |

Noise | / | <60dB |

1. Graphene dispersion

2. Silica dispersion

3. Paint dispersion

4. Alumina dispersion

5. Lithium battery slurry

6. Nano materials

1) Compared with the traditional mixing and ball milling process, the operation cost per unit capacity can be greatly reduced. It is especially suitable for industrial production.

2) For liquid-liquid mixture, the chemical reaction speed can be increased, the amount of additives can be reduced, and the fully mixed solution is not suitable for stratification for a long time.

3) For the solid-liquid mixture, the easily agglomerated nanoparticles can be opened in a short time, and the dispersed ultrafine particles are not easy to agglomerate again.

1. Core parts with Titanium materials

2. Ultrasonic horn(probe) with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability, long working hours, radiation area is increased 2.5 times than traditional tools

7. High amplitude to let ultrasonic cavitation strength to process liquids more efficiency

8. Provide consulting services and custom reactor designs

9. Custom sizes available for laboratory and high volume industrial applications

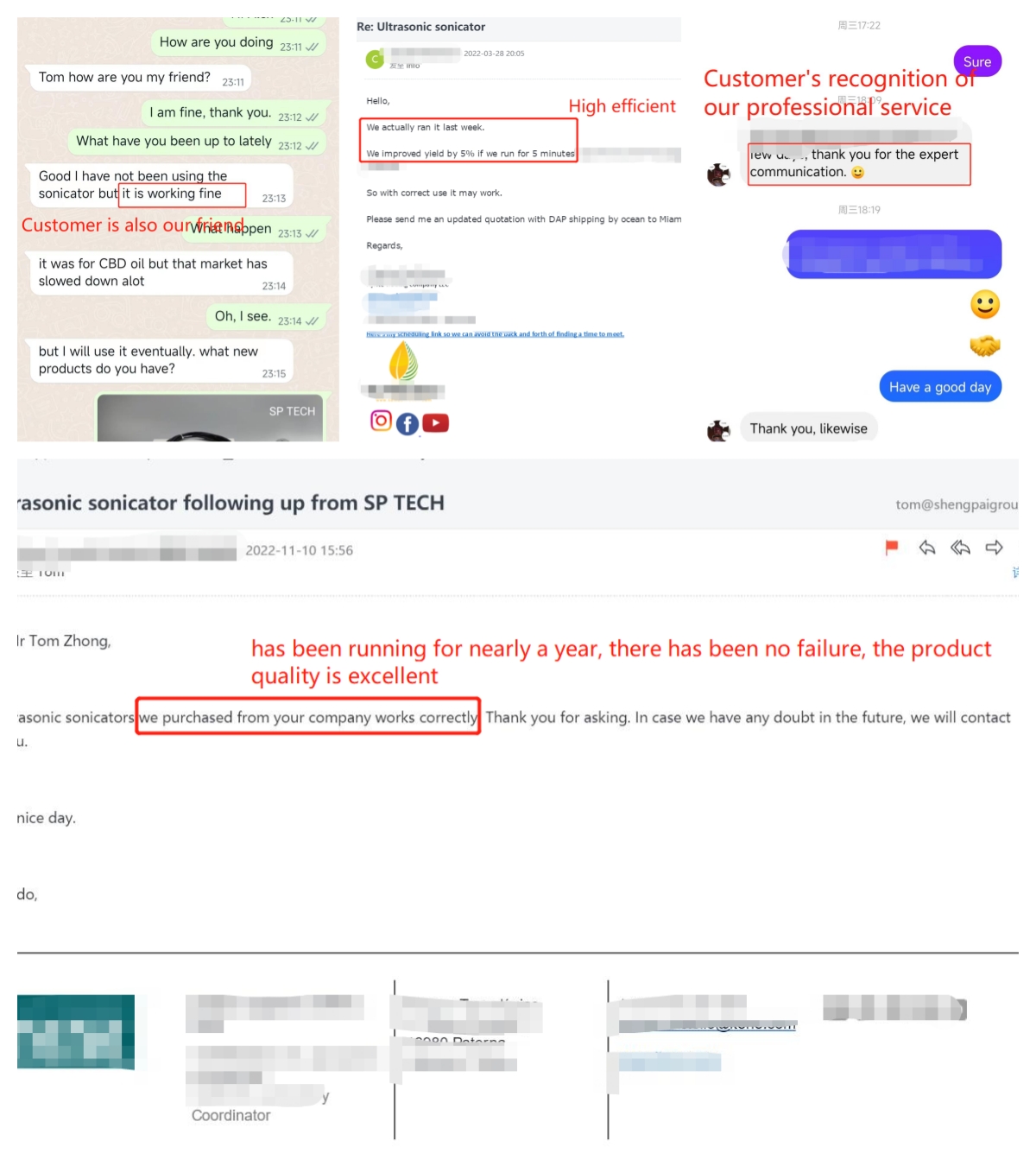

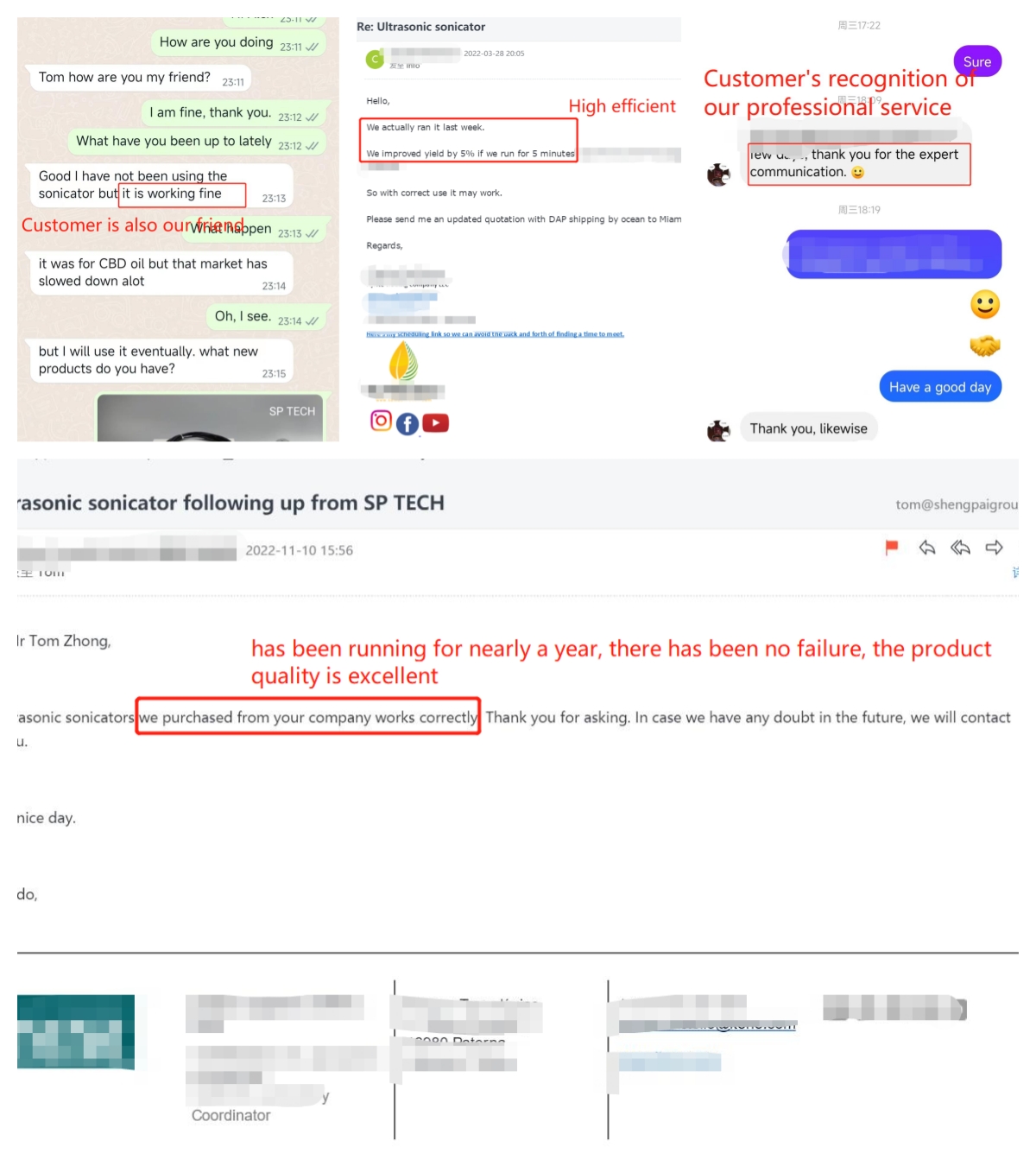

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic disperser is a kind of dispersing means with high intensity and best effect by directly placing the particle suspension to be treated in the ultrasonic field and "irradiating" with high-power ultrasonic waves.

First of all, the propagation of ultrasound needs to be based on the medium.

The propagation of ultrasonic waves in the medium has an alternating cycle of positive and negative pressures. The medium is squeezed and pulled under the positive and negative pressure of the colloid.

When ultrasonic waves act on the medium liquid, the distance between the molecules in the negative pressure zone will exceed the critical molecular distance that the liquid medium remains unchanged. The liquid medium will break, forming micro bubbles, and the micro bubbles will become cavitation.

The bubble can be redissolved in the gas, it can also float up and disappear, or it may collapse from the resonance phase of the ultrasonic field. It produces local high temperature and high pressure, and produce huge impact force and micro jet. Under the action of nano particle, the surface energy can be weakened, thus achieving the dispersion of nano particle.

Item No. | Parameters | |

Type | SPS20-500S | SPS20-1000S |

Ultrasonic Power(W) | 500 | 1000 |

Cooling Power(W) | / | 200 |

Amplitude Range(um) | 0-50 | |

Processing Capacity(L/H) | 0.5-2.0 | 1.0-4.0 |

Constant Temperature Control(℃) | / | 10-75 |

Cavitation Intensity (w/cm2) | 0-5.0 | |

Reaction Device | Beaker | Reaction kettle/ Beaker |

Volume(ml) | 500 | 500-1000 |

Noise | / | <60dB |

1. Graphene dispersion

2. Silica dispersion

3. Paint dispersion

4. Alumina dispersion

5. Lithium battery slurry

6. Nano materials

1) Compared with the traditional mixing and ball milling process, the operation cost per unit capacity can be greatly reduced. It is especially suitable for industrial production.

2) For liquid-liquid mixture, the chemical reaction speed can be increased, the amount of additives can be reduced, and the fully mixed solution is not suitable for stratification for a long time.

3) For the solid-liquid mixture, the easily agglomerated nanoparticles can be opened in a short time, and the dispersed ultrafine particles are not easy to agglomerate again.

1. Core parts with Titanium materials

2. Ultrasonic horn(probe) with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 1% to 99%

6. Amplitude stability, long working hours, radiation area is increased 2.5 times than traditional tools

7. High amplitude to let ultrasonic cavitation strength to process liquids more efficiency

8. Provide consulting services and custom reactor designs

9. Custom sizes available for laboratory and high volume industrial applications

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.