| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000/2000/3000

SP

8543709990

Ultrasonic particle dispersion is a technique used to break up agglomerates or clusters of particles in a sample, creating a more homogeneous dispersion of individual particles. This is achieved by exposing the sample to high-frequency sound waves, typically in the range of 20 kHz to 100 kHz, which creates cavitation in the sample, leading to the formation and collapse of microbubbles.

During ultrasonic particle dispersion, the sound waves create alternating high-pressure and low-pressure cycles in the liquid medium surrounding the particles, which leads to the formation of microbubbles in the liquid. These microbubbles grow and then violently collapse, generating high shear forces and intense shock waves. These forces break up agglomerates or clusters of particles, creating a more uniform dispersion of individual particles.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic particle dispersion is a widely used technique in various fields, including materials science, nanotechnology, and biotechnology. It is used to disperse particles in a wide range of media, including water, solvents, and polymers. Some common applications of ultrasonic particle dispersion include:

1. Nanoparticle synthesis: Ultrasonic particle dispersion is used in the production of nanoparticles to create a more uniform distribution of particles and to prevent agglomeration.

2. Drug delivery: Ultrasonic particle dispersion is used to create drug-loaded nanoparticles with a more homogeneous particle size distribution for improved drug delivery.

3. Paint and coating formulation: Ultrasonic particle dispersion is used to disperse pigments and other particles in paint and coating formulations to create a more even and consistent color.

4. Sample preparation for analytical techniques: Ultrasonic particle dispersion is used to prepare samples for various analytical techniques, such as microscopy, spectroscopy, and chromatography.

Overall, ultrasonic particle dispersion is a powerful and versatile technique that is widely used in various scientific and industrial applications to create a more uniform dispersion of particles.

Ultrasonic dispersers are powerful, but they also generate a lot of heat and noise as a result of their use of ultrasonic energy.

Therefore, it is highly recommended that you use ear protectors and/or keep them in an insulated housing to reduce noise levels during the dispersing process.

Reaction kettle, cooling device and circulation device can be designed according to your application requirements.

To maximize the life of the speaker, clean and dry the speaker after each use.

Failure to properly maintain the horn can lead to pitting (localized corrosion that creates holes in the titanium), which can reduce the horn's effectiveness.

Ultrasonic disperser must be used with liquid samples.

They are not suitable for dry homogenization applications.

Immerse the horn into the sample before turning on the instrument and ensure that the horn does not touch the sides of the container during operation.

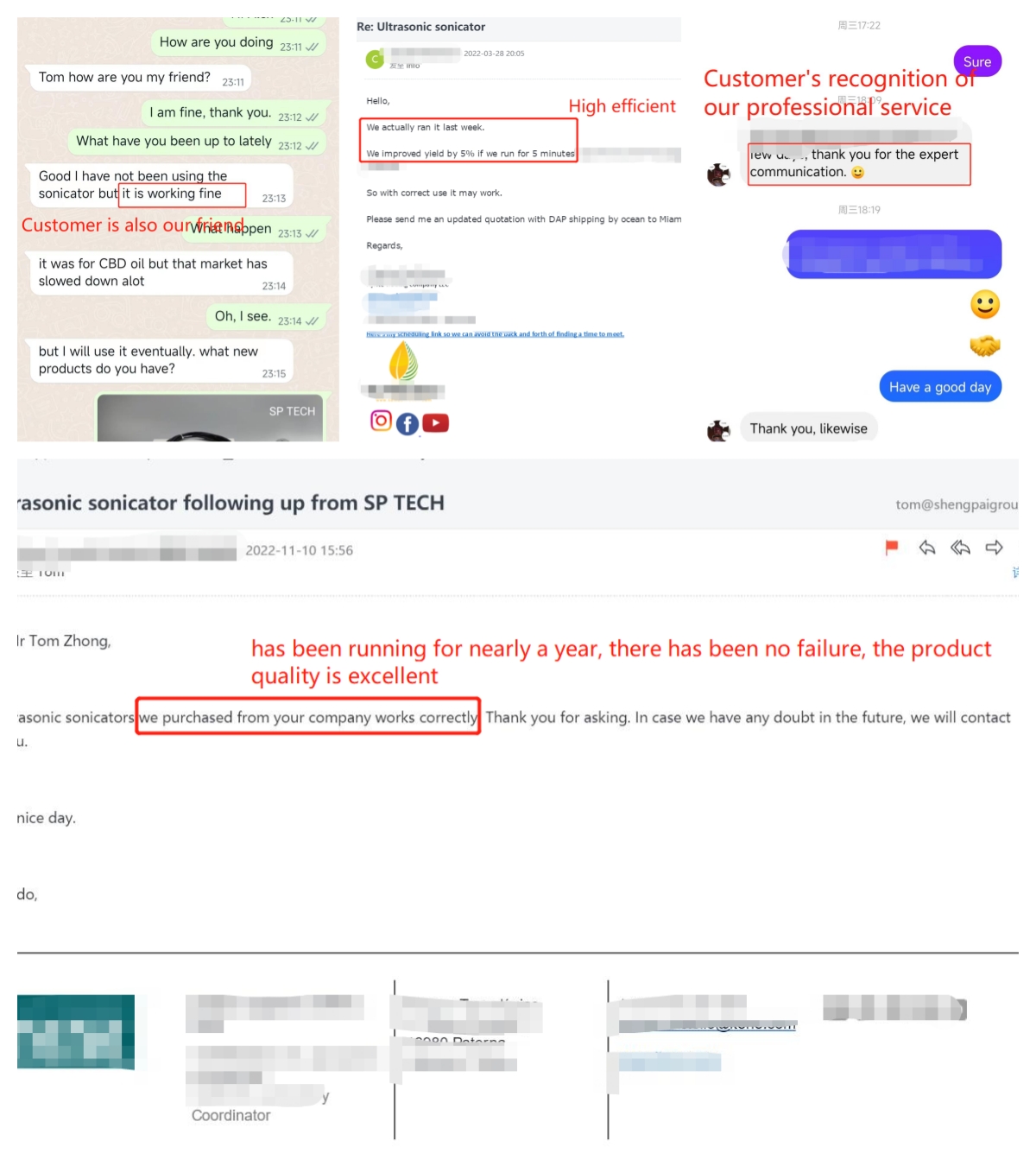

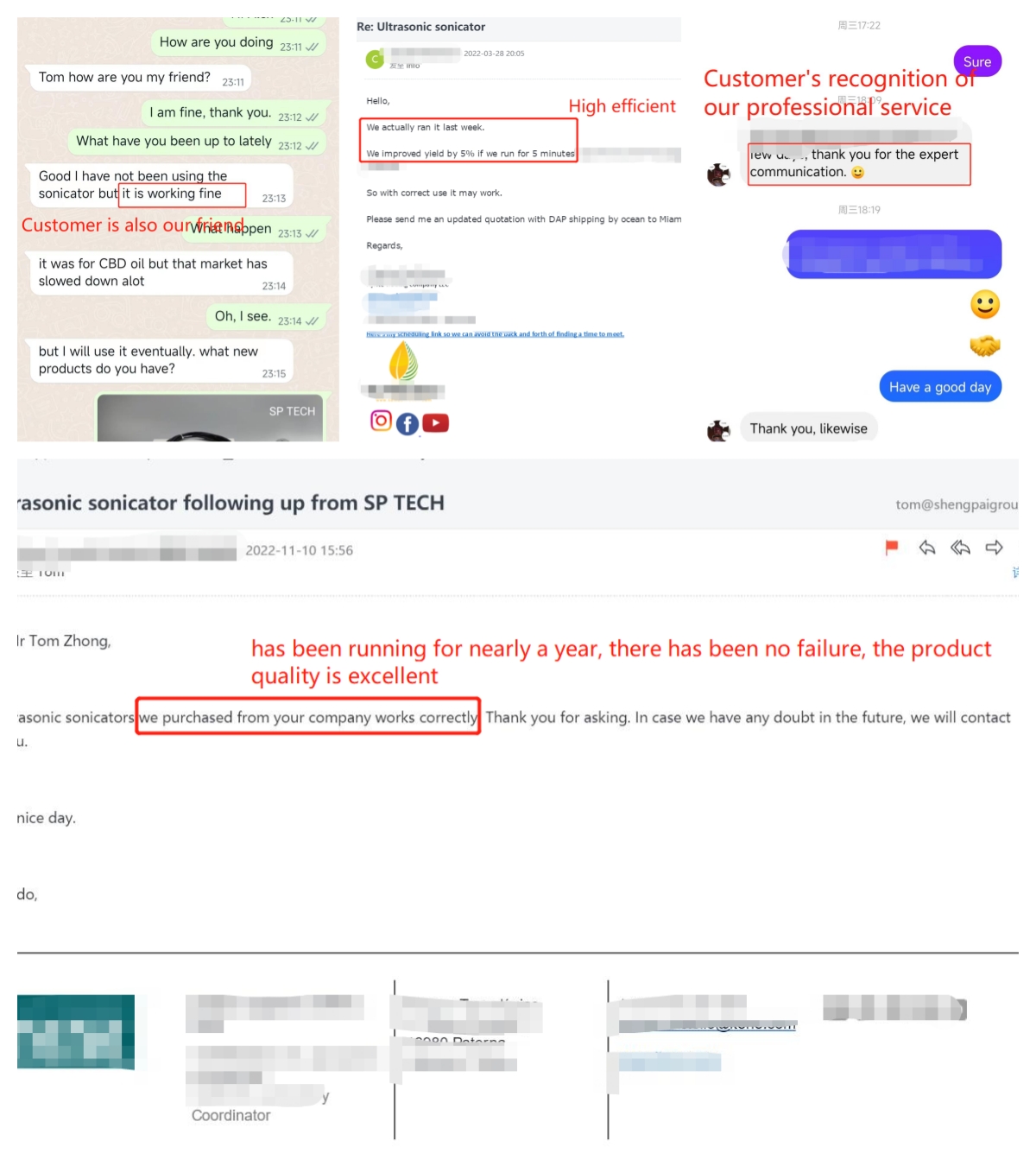

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic particle dispersion is a technique used to break up agglomerates or clusters of particles in a sample, creating a more homogeneous dispersion of individual particles. This is achieved by exposing the sample to high-frequency sound waves, typically in the range of 20 kHz to 100 kHz, which creates cavitation in the sample, leading to the formation and collapse of microbubbles.

During ultrasonic particle dispersion, the sound waves create alternating high-pressure and low-pressure cycles in the liquid medium surrounding the particles, which leads to the formation of microbubbles in the liquid. These microbubbles grow and then violently collapse, generating high shear forces and intense shock waves. These forces break up agglomerates or clusters of particles, creating a more uniform dispersion of individual particles.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic particle dispersion is a widely used technique in various fields, including materials science, nanotechnology, and biotechnology. It is used to disperse particles in a wide range of media, including water, solvents, and polymers. Some common applications of ultrasonic particle dispersion include:

1. Nanoparticle synthesis: Ultrasonic particle dispersion is used in the production of nanoparticles to create a more uniform distribution of particles and to prevent agglomeration.

2. Drug delivery: Ultrasonic particle dispersion is used to create drug-loaded nanoparticles with a more homogeneous particle size distribution for improved drug delivery.

3. Paint and coating formulation: Ultrasonic particle dispersion is used to disperse pigments and other particles in paint and coating formulations to create a more even and consistent color.

4. Sample preparation for analytical techniques: Ultrasonic particle dispersion is used to prepare samples for various analytical techniques, such as microscopy, spectroscopy, and chromatography.

Overall, ultrasonic particle dispersion is a powerful and versatile technique that is widely used in various scientific and industrial applications to create a more uniform dispersion of particles.

Ultrasonic dispersers are powerful, but they also generate a lot of heat and noise as a result of their use of ultrasonic energy.

Therefore, it is highly recommended that you use ear protectors and/or keep them in an insulated housing to reduce noise levels during the dispersing process.

Reaction kettle, cooling device and circulation device can be designed according to your application requirements.

To maximize the life of the speaker, clean and dry the speaker after each use.

Failure to properly maintain the horn can lead to pitting (localized corrosion that creates holes in the titanium), which can reduce the horn's effectiveness.

Ultrasonic disperser must be used with liquid samples.

They are not suitable for dry homogenization applications.

Immerse the horn into the sample before turning on the instrument and ensure that the horn does not touch the sides of the container during operation.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.