| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000/2000/3000

SP

8543709990

Our ultrasonic sonicator focused on the r&d of high power ultrasound applications. It has absolute leading core technology, the most stable and mature manufacturing technology, rich experience, can provide direct ultrasonic application scheme demonstrate, structure design, system configuration and related parts production.

Ultrasound is a well-established method for emulsifying. Ultrasonic processors are used in the generation of nano-size material slurries, dispersions and emulsions because of the potential in the deagglomeration and the reduction of primaries. These are the mechanical effects of ultrsonic cavitation. Ultrasonic can also be used to influence chemical reactions by the cavitation energy.

As the market for nano-size materials grows, the demand for ultrasonic processes at production level increases.

Ultrasonic sonicator is mainly composed of two parts, an ultrasonic drive generator and an ultrasonic vibration equipment(ultrasonic transducer with booster and probe), which are connected by a dedicated cable.

Ultrasonic generator is used to convert 50-60HZ mains power (AC 220V) into high-power, high-frequency electrical signals and output to ultrasonic vibration components. Ultrasonic vibration equipment mainly includes high-power ultrasonic transducer, booster,flange and probe, which are used to generate ultrasonic vibrations and emit this vibration energy to the process objects. The transducer stretches back and forth in the longitudinal direction to convert the input electric energy into mechanical energy (ultrasound). The booster amplifies the amplitude according to the design requirements, and isolates the reaction solution and the transducer. Generally, flange (or quick clip) is connected between booster and probe, and the flange plays a role in fixing the entire ultrasonic vibration system. The booster is connected to probe, and booster transmits ultrasonic vibration energy transferred from transducer to probe, and finally transmits ultrasonic vibration energy to process object through probe.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic treatment of chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalytic efficiency of catalysts, biodegradation treatment, ultrasonic anti-scaling, biological cell comminution, dispersion and coagulation A local small environment that is very beneficial to the reaction process can greatly increase the reaction rate and reduce the reaction conditions.

1. The emulsification quality is high. The average droplet size of the formed emulsion is small, which can reach 0.2~2um. The droplet size distribution range is narrow, up to 0.1~10um. The concentration is high, the concentration of pure emulsion can reach 30%, adding emulsifier can reach 70%.

2. The emulsification is stable, you can produce stable emulsions without or with less emulsifiers, and some can be stable for several months or even more than half a year, with low energy consumption, high production efficiency and low cost.

3. The type of emulsion can be controlled. Under certain sound field conditions, both oil-in-water and water-in-oil emulsions can be prepared. However, it is impossible to achieve mechanical emulsification. Only the properties of emulsifiers can control the type of emulsion. For example, when toluene is emulsified in water, one type of emulsion can be formed under low sound intensity conditions, and another type of emulsion can be formed under high sound intensity conditions.

4. Low power required to produce emulsion.

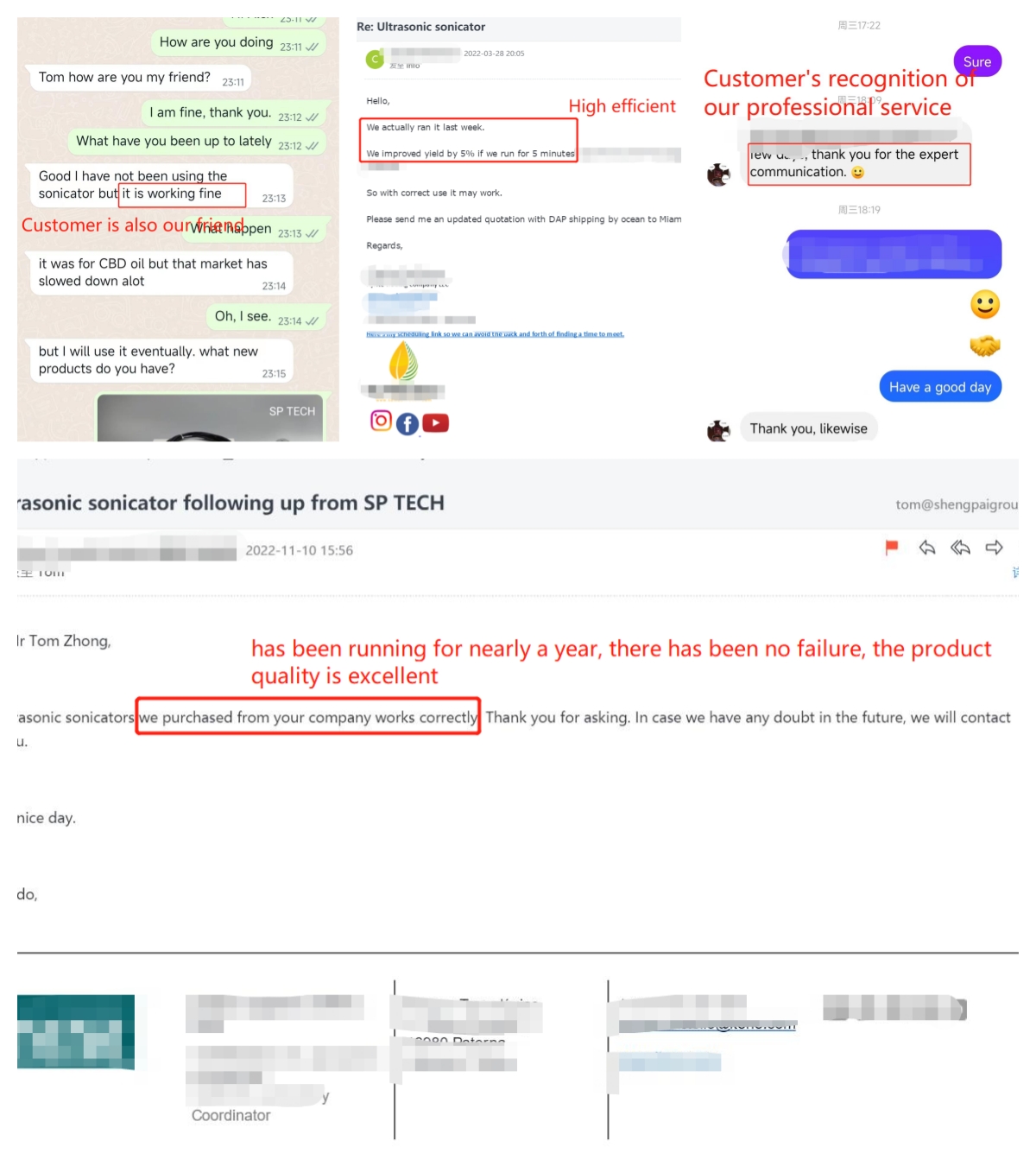

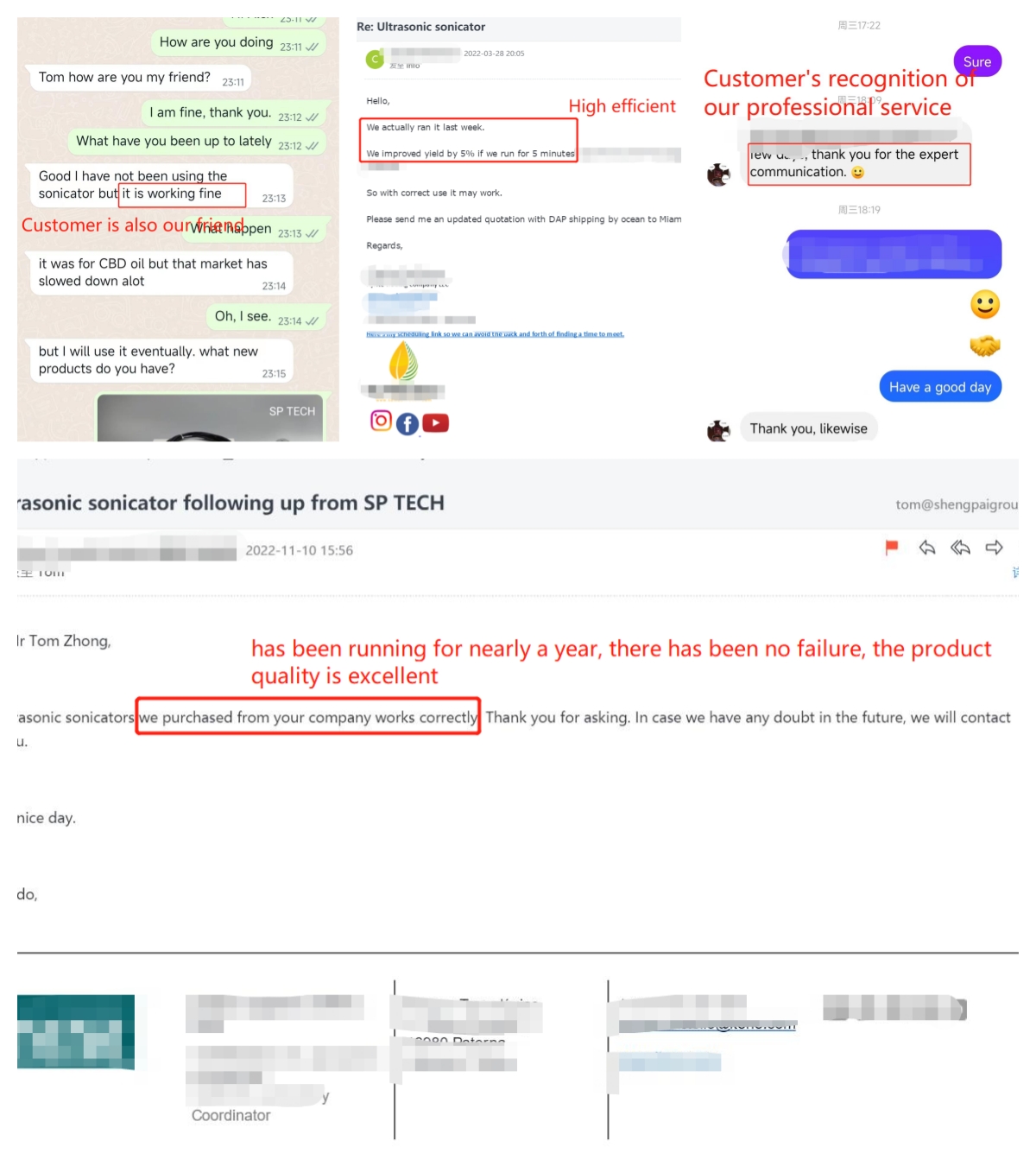

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Our ultrasonic sonicator focused on the r&d of high power ultrasound applications. It has absolute leading core technology, the most stable and mature manufacturing technology, rich experience, can provide direct ultrasonic application scheme demonstrate, structure design, system configuration and related parts production.

Ultrasound is a well-established method for emulsifying. Ultrasonic processors are used in the generation of nano-size material slurries, dispersions and emulsions because of the potential in the deagglomeration and the reduction of primaries. These are the mechanical effects of ultrsonic cavitation. Ultrasonic can also be used to influence chemical reactions by the cavitation energy.

As the market for nano-size materials grows, the demand for ultrasonic processes at production level increases.

Ultrasonic sonicator is mainly composed of two parts, an ultrasonic drive generator and an ultrasonic vibration equipment(ultrasonic transducer with booster and probe), which are connected by a dedicated cable.

Ultrasonic generator is used to convert 50-60HZ mains power (AC 220V) into high-power, high-frequency electrical signals and output to ultrasonic vibration components. Ultrasonic vibration equipment mainly includes high-power ultrasonic transducer, booster,flange and probe, which are used to generate ultrasonic vibrations and emit this vibration energy to the process objects. The transducer stretches back and forth in the longitudinal direction to convert the input electric energy into mechanical energy (ultrasound). The booster amplifies the amplitude according to the design requirements, and isolates the reaction solution and the transducer. Generally, flange (or quick clip) is connected between booster and probe, and the flange plays a role in fixing the entire ultrasonic vibration system. The booster is connected to probe, and booster transmits ultrasonic vibration energy transferred from transducer to probe, and finally transmits ultrasonic vibration energy to process object through probe.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic treatment of chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalytic efficiency of catalysts, biodegradation treatment, ultrasonic anti-scaling, biological cell comminution, dispersion and coagulation A local small environment that is very beneficial to the reaction process can greatly increase the reaction rate and reduce the reaction conditions.

1. The emulsification quality is high. The average droplet size of the formed emulsion is small, which can reach 0.2~2um. The droplet size distribution range is narrow, up to 0.1~10um. The concentration is high, the concentration of pure emulsion can reach 30%, adding emulsifier can reach 70%.

2. The emulsification is stable, you can produce stable emulsions without or with less emulsifiers, and some can be stable for several months or even more than half a year, with low energy consumption, high production efficiency and low cost.

3. The type of emulsion can be controlled. Under certain sound field conditions, both oil-in-water and water-in-oil emulsions can be prepared. However, it is impossible to achieve mechanical emulsification. Only the properties of emulsifiers can control the type of emulsion. For example, when toluene is emulsified in water, one type of emulsion can be formed under low sound intensity conditions, and another type of emulsion can be formed under high sound intensity conditions.

4. Low power required to produce emulsion.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.