| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

Ultrasonic sonifiers can be used for bacterial microbe degradation by disrupting the cell walls of the bacteria and causing them to break down. This can be a useful technique in many applications, including environmental remediation, wastewater treatment, and food safety.

The process involves immersing the sample in a liquid buffer and applying high-frequency sound waves to the sample. The sound waves cause cavitation, the formation and collapse of tiny bubbles in the liquid, which creates localized areas of high pressure and temperature. This pressure and temperature disrupt the cell walls of the bacteria, releasing the intracellular materials into the liquid buffer and ultimately causing the bacteria to degrade.

The effectiveness of ultrasonic sonification for bacterial microbe degradation depends on several factors, including the frequency and intensity of the sound waves, the duration of the treatment, and the sample type and preparation. It is important to optimize these parameters for each specific application to obtain the best results.

The SPS20-1000/2000/3000 ultrasonic sonifier is most commonly supplied with a 1000W/2000W/3000W ultrasonic digital generator, air cooling transducer, and full-wave horn(probe).

Optional items include a flowing reactor, different shape horn, flow meter, flange and transfer pump.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic sonifiers can be used to degrade a wide range of bacterial species, including gram-positive and gram-negative bacteria. They can also be used to target specific bacterial strains or groups of bacteria, depending on the application.

Overall, ultrasonic sonifiers can be a useful tool for bacterial microbe degradation, but it is important to use them with caution and with appropriate expertise. The process can also cause damage to other materials in the sample if not carefully controlled, so it is important to optimize the treatment conditions for each specific application.

Ultrasonic sonifiers, also known as ultrasonic homogenizers or sonicators, have several advantages over other homogenization and mixing techniques. Here are some of the key advantages of sonifiers:

1. High Efficiency: Ultrasonic sonifiers can homogenize or mix a sample quickly and efficiently, often in a matter of seconds or minutes. This efficiency can save time and resources, particularly in high-throughput applications.

2. Uniformity: Ultrasonic sonifiers can provide high levels of sample uniformity by breaking down large particles and creating smaller, more uniform particles or droplets. This can be particularly useful in applications where a consistent particle size or distribution is important.

3. Non-contact: Ultrasonic sonifiers work through a non-contact process, which means there is no need to use grinding or shearing blades, reducing the risk of contamination or mechanical damage to sensitive materials.

4. Versatility: Ultrasonic sonifiers can be used for a wide range of applications, including cell disruption, emulsification, dispersing, and extraction of various types of materials such as proteins, nucleic acids, and nanoparticles.

5. Scalability: Ultrasonic sonifiers are available in a wide range of sizes, making them suitable for small-scale laboratory work as well as larger-scale industrial production.

6. Easy to use: Ultrasonic sonifiers are generally easy to use and require minimal training, making them accessible to a wide range of users.

Overall, the advantages of ultrasonic sonifiers make them a valuable tool for many applications in various fields, including life sciences, chemistry, materials science, and engineering.

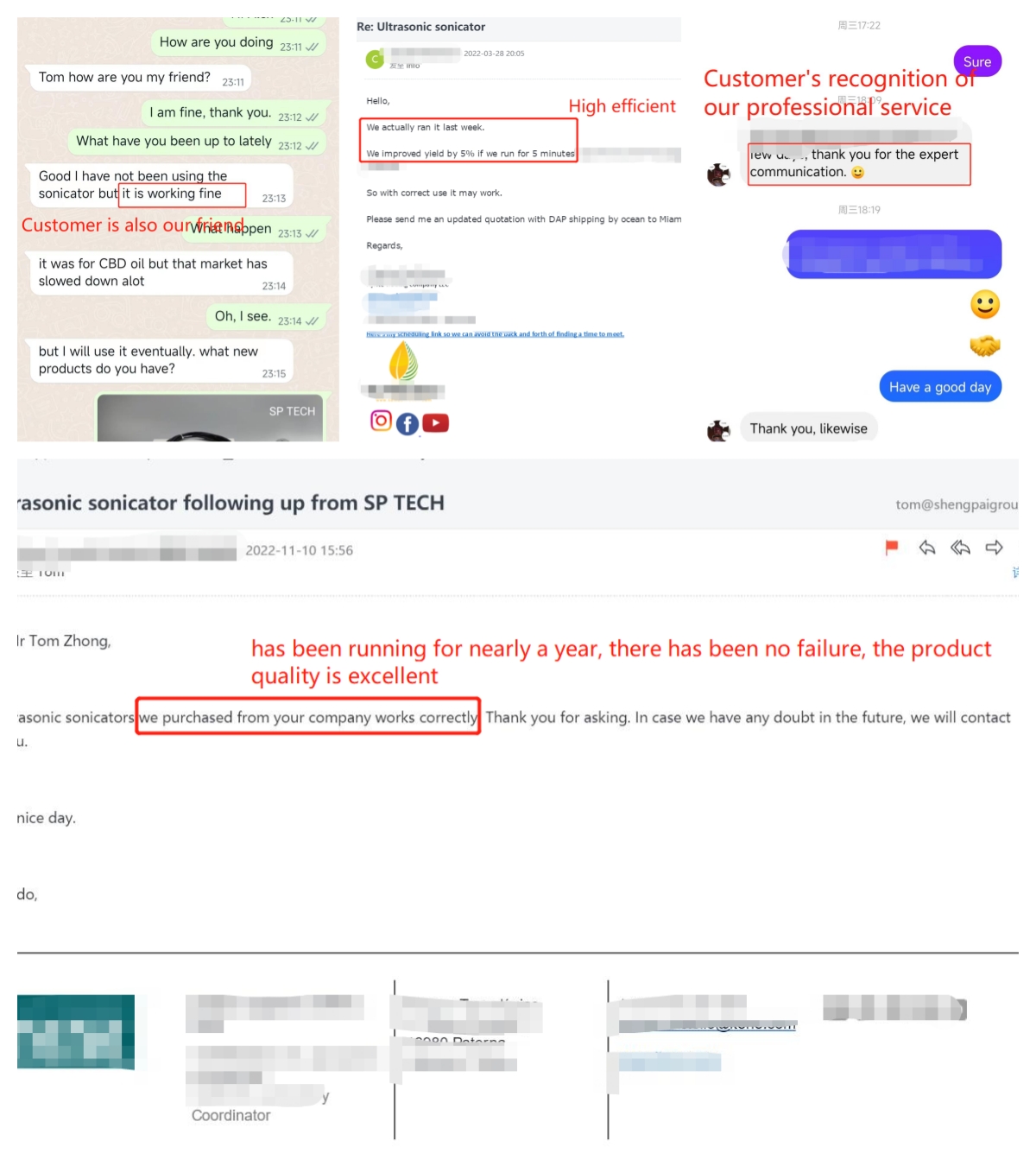

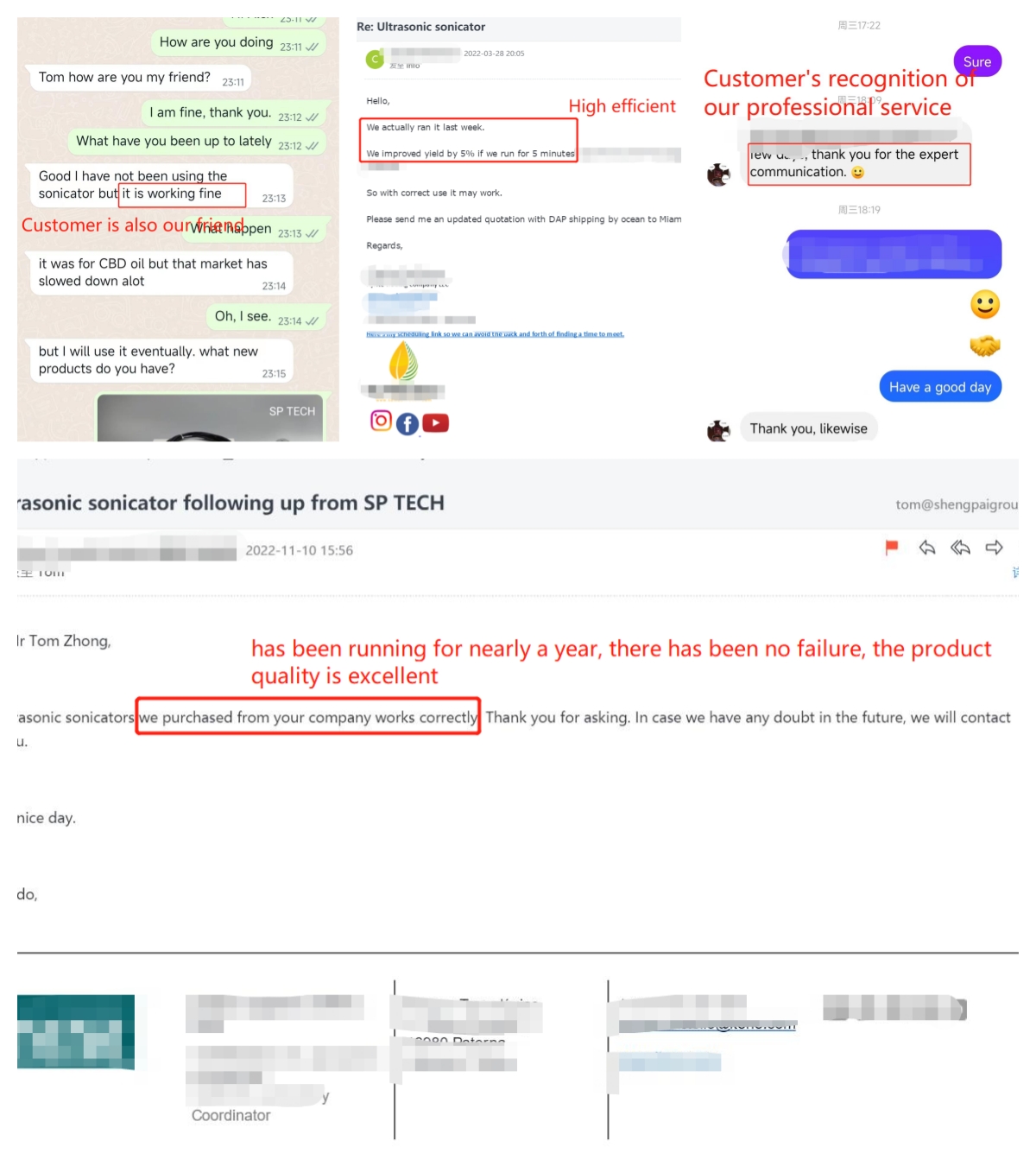

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic sonifiers can be used for bacterial microbe degradation by disrupting the cell walls of the bacteria and causing them to break down. This can be a useful technique in many applications, including environmental remediation, wastewater treatment, and food safety.

The process involves immersing the sample in a liquid buffer and applying high-frequency sound waves to the sample. The sound waves cause cavitation, the formation and collapse of tiny bubbles in the liquid, which creates localized areas of high pressure and temperature. This pressure and temperature disrupt the cell walls of the bacteria, releasing the intracellular materials into the liquid buffer and ultimately causing the bacteria to degrade.

The effectiveness of ultrasonic sonification for bacterial microbe degradation depends on several factors, including the frequency and intensity of the sound waves, the duration of the treatment, and the sample type and preparation. It is important to optimize these parameters for each specific application to obtain the best results.

The SPS20-1000/2000/3000 ultrasonic sonifier is most commonly supplied with a 1000W/2000W/3000W ultrasonic digital generator, air cooling transducer, and full-wave horn(probe).

Optional items include a flowing reactor, different shape horn, flow meter, flange and transfer pump.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic sonifiers can be used to degrade a wide range of bacterial species, including gram-positive and gram-negative bacteria. They can also be used to target specific bacterial strains or groups of bacteria, depending on the application.

Overall, ultrasonic sonifiers can be a useful tool for bacterial microbe degradation, but it is important to use them with caution and with appropriate expertise. The process can also cause damage to other materials in the sample if not carefully controlled, so it is important to optimize the treatment conditions for each specific application.

Ultrasonic sonifiers, also known as ultrasonic homogenizers or sonicators, have several advantages over other homogenization and mixing techniques. Here are some of the key advantages of sonifiers:

1. High Efficiency: Ultrasonic sonifiers can homogenize or mix a sample quickly and efficiently, often in a matter of seconds or minutes. This efficiency can save time and resources, particularly in high-throughput applications.

2. Uniformity: Ultrasonic sonifiers can provide high levels of sample uniformity by breaking down large particles and creating smaller, more uniform particles or droplets. This can be particularly useful in applications where a consistent particle size or distribution is important.

3. Non-contact: Ultrasonic sonifiers work through a non-contact process, which means there is no need to use grinding or shearing blades, reducing the risk of contamination or mechanical damage to sensitive materials.

4. Versatility: Ultrasonic sonifiers can be used for a wide range of applications, including cell disruption, emulsification, dispersing, and extraction of various types of materials such as proteins, nucleic acids, and nanoparticles.

5. Scalability: Ultrasonic sonifiers are available in a wide range of sizes, making them suitable for small-scale laboratory work as well as larger-scale industrial production.

6. Easy to use: Ultrasonic sonifiers are generally easy to use and require minimal training, making them accessible to a wide range of users.

Overall, the advantages of ultrasonic sonifiers make them a valuable tool for many applications in various fields, including life sciences, chemistry, materials science, and engineering.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.