| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000/2000/3000

SP

8543709990

1. Prepare the oil and water: Mix the oil and water together in a container to create the emulsion. Add any desired emulsifiers or stabilizers to help keep the emulsion stable.

2. Place the container in the ultrasonic homogenizer: Position the container of the emulsion mixture in the ultrasonic homogenizer. Use a probe that is compatible with the size and shape of the container to ensure efficient and effective mixing.

3. Ultrasonicate the emulsion mixture: Turn on the ultrasonic homogenizer and allow it to operate for a set period of time. The ultrasonic waves generated by the homogenizer will create high shear forces, which will break down the oil droplets and disperse them evenly throughout the water.

4. Analyze and adjust the emulsion: After ultrasonication, analyze the emulsion to ensure that it has the desired characteristics, such as droplet size and stability. If necessary, adjust the emulsion by adding additional emulsifiers or stabilizers and repeating the ultrasonication process.

Overall, ultrasonic homogenizers are a powerful tool for creating stable and uniform oil and water emulsions, which can be used in a variety of industries, including food, cosmetics, and pharmaceuticals.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Food and Beverage Industry: Ultrasonic sonicators are used to create stable emulsions of oil and water in food products such as salad dressings, mayonnaise, and sauces. Ultrasonic sonicators can also be used to create nanoemulsions, which can improve the bioavailability and stability of certain food ingredients.

2. Cosmetic Industry: Ultrasonic sonicators are used to create stable emulsions of oil and water in cosmetic products such as lotions, creams, and sunscreens. Ultrasonic sonicators can also be used to create nanoemulsions, which can improve the absorption and effectiveness of certain cosmetic ingredients.

3. Pharmaceutical Industry: Ultrasonic sonicators are used to create emulsions of oil and water in pharmaceutical products such as vaccines and injectables. Ultrasonic sonicators can also be used to create liposomal formulations, which can improve the delivery of drugs to target tissues.

4. Chemical Industry: Ultrasonic sonicators are used to create emulsions of various chemicals for industrial applications such as paint, coatings, and lubricants. Ultrasonic sonicators can improve the stability and consistency of these products.

Overall, ultrasonic sonicators are a versatile tool for creating stable emulsions of oil and water in a variety of industries. By using ultrasonic energy, emulsions can be created more quickly and with a higher level of control, resulting in improved product quality and efficiency.

1. The reaction speed is fast, compared with the traditional method, the output is higher under the action of ultrasound

2. The material extracted by ultrasound is more pure and of better quality.

3. Basically compatible with any solvent

4. Simple and safe operation

5. Linear scalability

6. Environmental protection, fast return on investment

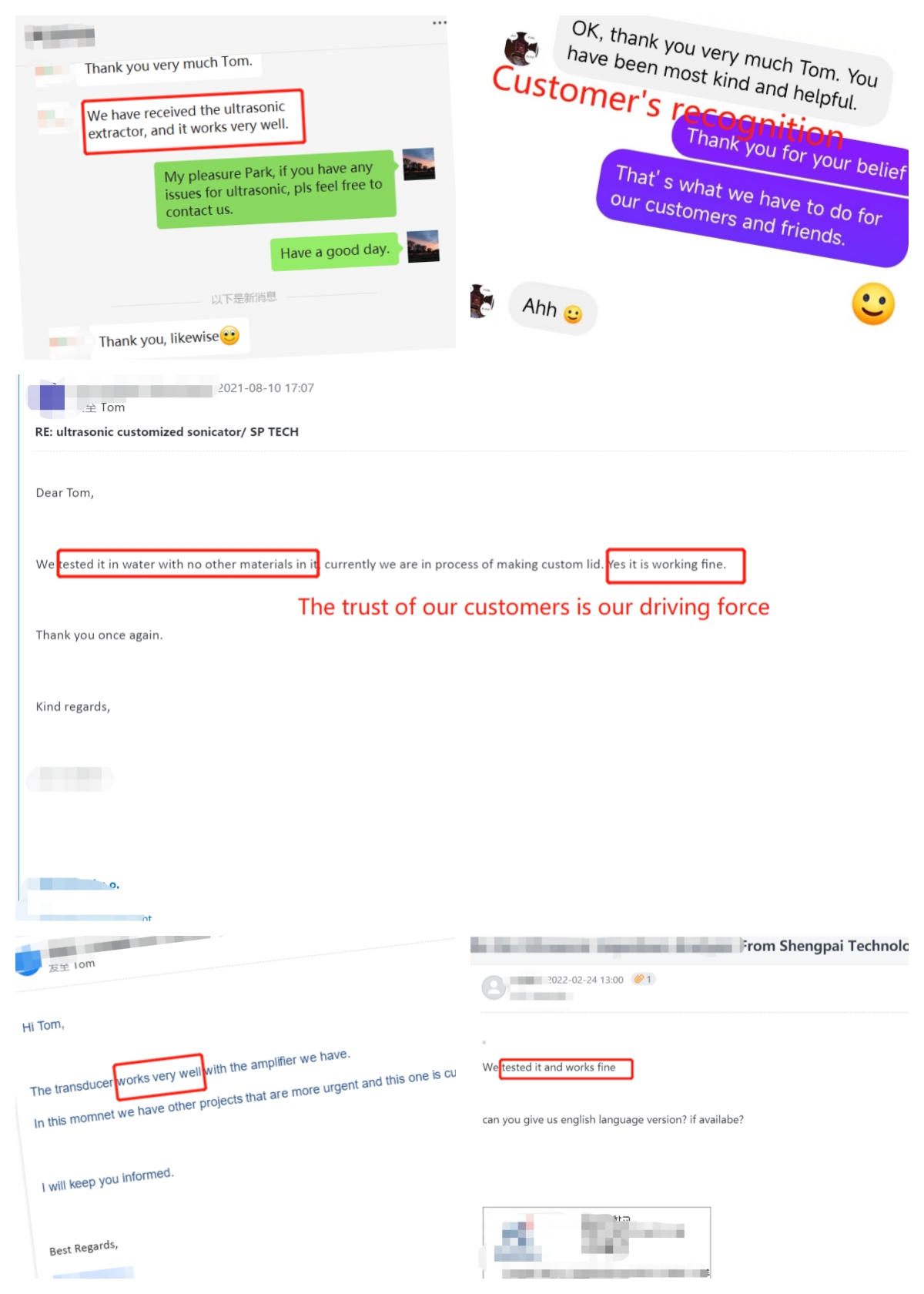

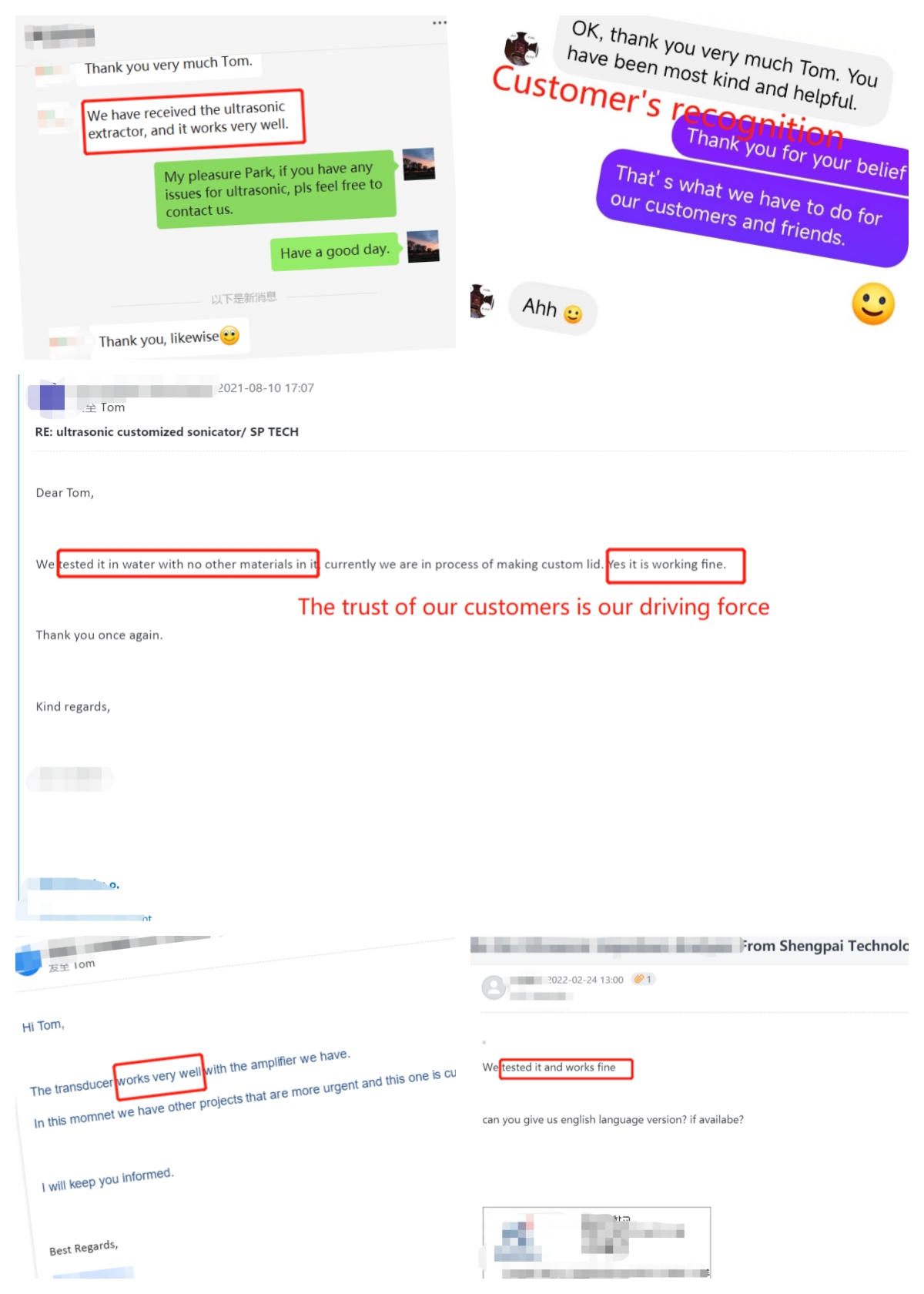

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

Our company recently purchased an ultrasonic sonicator for use in our manufacturing process, and it has been a great investment. But the sonicator has improved our product quality and helped us to reduce production time, which has led to significant cost savings. We are very satisfied with our purchase.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. Prepare the oil and water: Mix the oil and water together in a container to create the emulsion. Add any desired emulsifiers or stabilizers to help keep the emulsion stable.

2. Place the container in the ultrasonic homogenizer: Position the container of the emulsion mixture in the ultrasonic homogenizer. Use a probe that is compatible with the size and shape of the container to ensure efficient and effective mixing.

3. Ultrasonicate the emulsion mixture: Turn on the ultrasonic homogenizer and allow it to operate for a set period of time. The ultrasonic waves generated by the homogenizer will create high shear forces, which will break down the oil droplets and disperse them evenly throughout the water.

4. Analyze and adjust the emulsion: After ultrasonication, analyze the emulsion to ensure that it has the desired characteristics, such as droplet size and stability. If necessary, adjust the emulsion by adding additional emulsifiers or stabilizers and repeating the ultrasonication process.

Overall, ultrasonic homogenizers are a powerful tool for creating stable and uniform oil and water emulsions, which can be used in a variety of industries, including food, cosmetics, and pharmaceuticals.

Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1000 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Food and Beverage Industry: Ultrasonic sonicators are used to create stable emulsions of oil and water in food products such as salad dressings, mayonnaise, and sauces. Ultrasonic sonicators can also be used to create nanoemulsions, which can improve the bioavailability and stability of certain food ingredients.

2. Cosmetic Industry: Ultrasonic sonicators are used to create stable emulsions of oil and water in cosmetic products such as lotions, creams, and sunscreens. Ultrasonic sonicators can also be used to create nanoemulsions, which can improve the absorption and effectiveness of certain cosmetic ingredients.

3. Pharmaceutical Industry: Ultrasonic sonicators are used to create emulsions of oil and water in pharmaceutical products such as vaccines and injectables. Ultrasonic sonicators can also be used to create liposomal formulations, which can improve the delivery of drugs to target tissues.

4. Chemical Industry: Ultrasonic sonicators are used to create emulsions of various chemicals for industrial applications such as paint, coatings, and lubricants. Ultrasonic sonicators can improve the stability and consistency of these products.

Overall, ultrasonic sonicators are a versatile tool for creating stable emulsions of oil and water in a variety of industries. By using ultrasonic energy, emulsions can be created more quickly and with a higher level of control, resulting in improved product quality and efficiency.

1. The reaction speed is fast, compared with the traditional method, the output is higher under the action of ultrasound

2. The material extracted by ultrasound is more pure and of better quality.

3. Basically compatible with any solvent

4. Simple and safe operation

5. Linear scalability

6. Environmental protection, fast return on investment

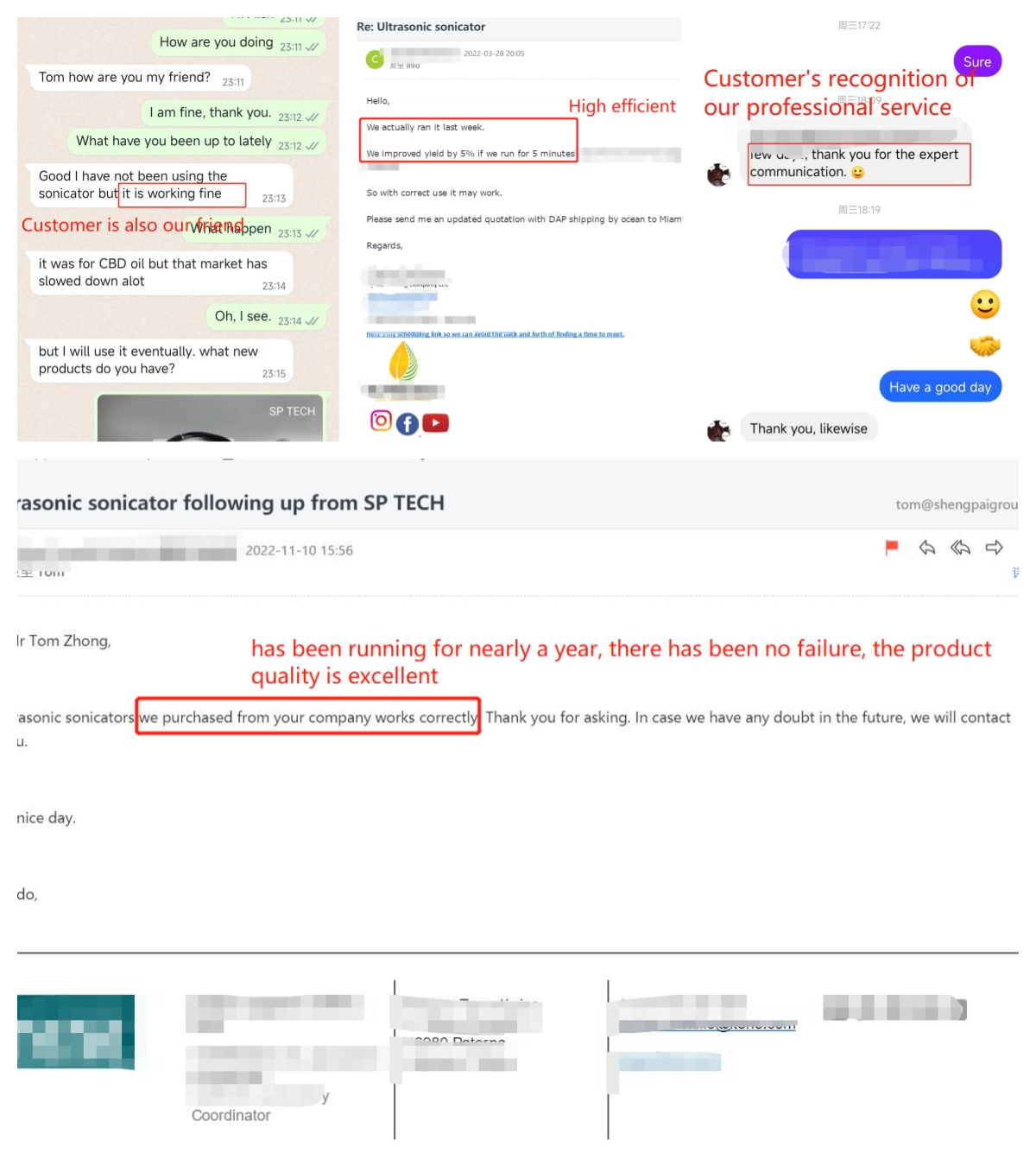

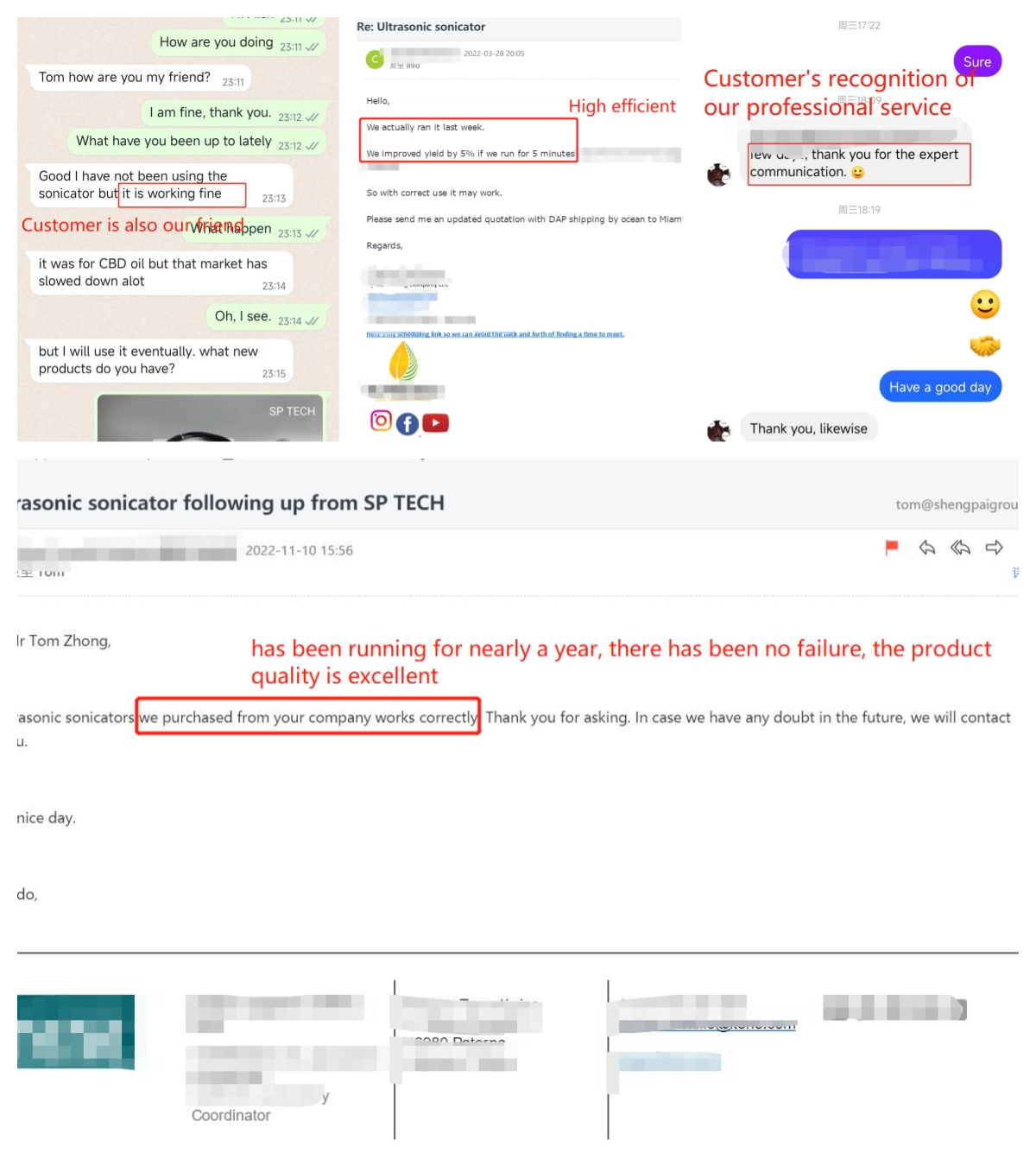

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

Our company recently purchased an ultrasonic sonicator for use in our manufacturing process, and it has been a great investment. But the sonicator has improved our product quality and helped us to reduce production time, which has led to significant cost savings. We are very satisfied with our purchase.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.