| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

The Ultrasonic Liquid Processor is a cutting-edge equipment designed for efficient and precise liquid processing in various industries. Utilizing advanced ultrasonic technology, this processor offers unparalleled performance and reliability. With its exceptional features, advantages, and wide range of applications, it is the ultimate solution for ultrasonic herbs extraction and homogenization.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Ultrasonic Herbs Extraction: The processor employs ultrasonic waves to extract active compounds from herbs, ensuring maximum potency and purity. It enables efficient extraction of essential oils, antioxidants, and other valuable components, enhancing the quality of herbal products.

2. Ultrasonic Homogenizer: With its powerful ultrasonic cavitation effect, the processor homogenizes liquids by effectively dispersing and emulsifying particles. It ensures uniform mixing, eliminates sedimentation, and enhances the stability of emulsions, suspensions, and solutions.

3. Precise Control: The processor offers precise control of ultrasonic parameters such as amplitude, frequency, and processing time. This allows customization according to specific processing requirements, ensuring optimal results for different applications.

4. Easy Operation: Featuring a user-friendly interface and intuitive controls, the processor is easy to operate. It offers pre-programmed settings for common applications, simplifying the processing procedure and saving time.

Advantages:

1. Enhanced Efficiency: The ultrasonic technology employed by the processor significantly reduces processing time compared to traditional methods. It accelerates extraction and homogenization processes, improving productivity and overall efficiency.

2. Preservation of Nutrients: The gentle yet powerful ultrasonic waves preserve the integrity of sensitive compounds, such as vitamins and enzymes, during processing. This ensures the retention of nutritional value and bioactivity in the final product.

3. Versatility: The processor is suitable for a wide range of liquid processing applications, including herbal medicine, pharmaceuticals, cosmetics, food and beverage, and more. It offers versatility and adaptability to meet diverse industry requirements.

4. Scalability: The processor is available in various capacities, allowing scalability to accommodate different production volumes. Whether for small-scale laboratory research or large-scale industrial production, it can be tailored to meet specific needs.

The Ultrasonic Liquid Processor finds extensive application in multiple industries:

1. Herbal Medicine: Enables efficient extraction of active compounds from herbs for the production of herbal extracts, tinctures, and essential oils.

2. Pharmaceutical: Facilitates the homogenization of pharmaceutical formulations, ensuring uniformity and stability of suspensions, emulsions, and solutions.

3. Cosmetics: Enhances the formulation of cosmetic products, enabling effective dispersion of ingredients and improving product texture and stability.

4. Food and Beverage: Enables emulsification, dispersion, and extraction processes in the food and beverage industry, enhancing product quality and shelf life.

5. Chemical: Ideal for mixing, dispersing, and emulsifying chemical compounds, facilitating research and development in the chemical industry.

6. Research and Development: Provides a reliable tool for laboratory-scale research, enabling scientists to explore innovative liquid processing techniques and formulations.

7. Biofuel Production: Assists in the extraction and processing of biofuel feedstocks, improving efficiency and yield in biofuel production processes.

8. Environmental Science: Supports various environmental science applications, including wastewater treatment, sample preparation, and pollutant removal.

9. Nanotechnology: Aids in the preparation of nanomaterials and nanoparticles, enabling precise control over particle size and distribution.

10. Veterinary and Animal Health: Facilitates the formulation of veterinary medicines and animal health products, ensuring uniformity and effectiveness.

1. Is the processor suitable for both liquid extraction and homogenization?

Yes, it can be used for other liquid extraction, homogenization or dispersing.

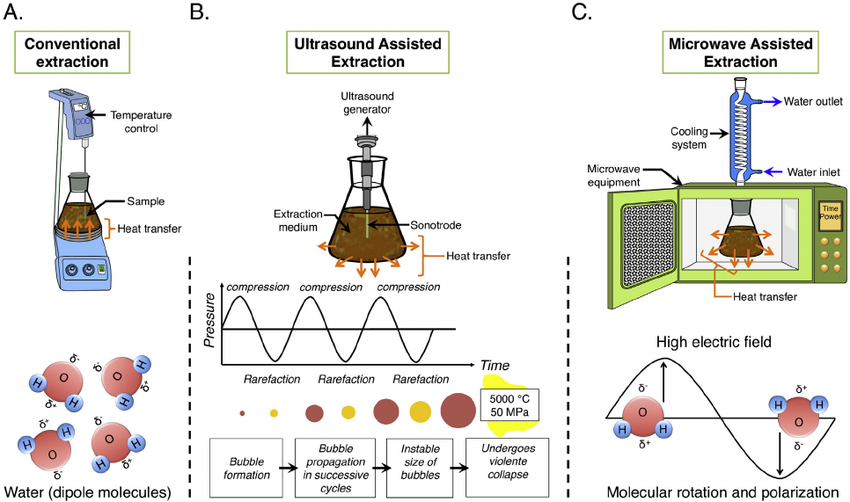

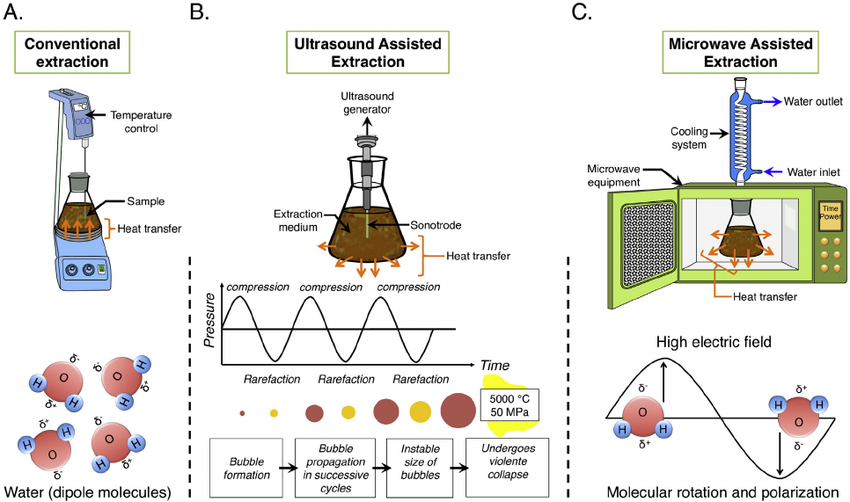

2. What is cavitation, and how does it enhance liquid processing?

Cavitation is the formation and collapse of tiny bubbles in a liquid due to ultrasonic waves. These collapsing bubbles create intense shockwaves that break down particles, facilitating efficient mixing, extraction, and homogenization in liquid processing.

3. Can I customize the processor's settings for different applications?

Yes, our High Power Ultrasonic Liquid Processor offers precise control over intensity, frequency, and processing time. This enables you to tailor the settings to suit various applications and achieve optimal results.

4. What kind of maintenance does the processor require?

The processor is designed for easy maintenance. Regular cleaning of the ultrasonic probe and vessel, along with routine checks for wear and tear, ensures consistent performance. Detailed maintenance guidelines are provided in the user manual.

5. Is this processor suitable for small-scale operations?

Absolutely, our High Power Ultrasonic Liquid Processor is versatile and can be scaled to accommodate both small and large-scale operations, making it suitable for businesses of varying sizes.

The Ultrasonic Liquid Processor is a cutting-edge equipment designed for efficient and precise liquid processing in various industries. Utilizing advanced ultrasonic technology, this processor offers unparalleled performance and reliability. With its exceptional features, advantages, and wide range of applications, it is the ultimate solution for ultrasonic herbs extraction and homogenization.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Ultrasonic Herbs Extraction: The processor employs ultrasonic waves to extract active compounds from herbs, ensuring maximum potency and purity. It enables efficient extraction of essential oils, antioxidants, and other valuable components, enhancing the quality of herbal products.

2. Ultrasonic Homogenizer: With its powerful ultrasonic cavitation effect, the processor homogenizes liquids by effectively dispersing and emulsifying particles. It ensures uniform mixing, eliminates sedimentation, and enhances the stability of emulsions, suspensions, and solutions.

3. Precise Control: The processor offers precise control of ultrasonic parameters such as amplitude, frequency, and processing time. This allows customization according to specific processing requirements, ensuring optimal results for different applications.

4. Easy Operation: Featuring a user-friendly interface and intuitive controls, the processor is easy to operate. It offers pre-programmed settings for common applications, simplifying the processing procedure and saving time.

Advantages:

1. Enhanced Efficiency: The ultrasonic technology employed by the processor significantly reduces processing time compared to traditional methods. It accelerates extraction and homogenization processes, improving productivity and overall efficiency.

2. Preservation of Nutrients: The gentle yet powerful ultrasonic waves preserve the integrity of sensitive compounds, such as vitamins and enzymes, during processing. This ensures the retention of nutritional value and bioactivity in the final product.

3. Versatility: The processor is suitable for a wide range of liquid processing applications, including herbal medicine, pharmaceuticals, cosmetics, food and beverage, and more. It offers versatility and adaptability to meet diverse industry requirements.

4. Scalability: The processor is available in various capacities, allowing scalability to accommodate different production volumes. Whether for small-scale laboratory research or large-scale industrial production, it can be tailored to meet specific needs.

The Ultrasonic Liquid Processor finds extensive application in multiple industries:

1. Herbal Medicine: Enables efficient extraction of active compounds from herbs for the production of herbal extracts, tinctures, and essential oils.

2. Pharmaceutical: Facilitates the homogenization of pharmaceutical formulations, ensuring uniformity and stability of suspensions, emulsions, and solutions.

3. Cosmetics: Enhances the formulation of cosmetic products, enabling effective dispersion of ingredients and improving product texture and stability.

4. Food and Beverage: Enables emulsification, dispersion, and extraction processes in the food and beverage industry, enhancing product quality and shelf life.

5. Chemical: Ideal for mixing, dispersing, and emulsifying chemical compounds, facilitating research and development in the chemical industry.

6. Research and Development: Provides a reliable tool for laboratory-scale research, enabling scientists to explore innovative liquid processing techniques and formulations.

7. Biofuel Production: Assists in the extraction and processing of biofuel feedstocks, improving efficiency and yield in biofuel production processes.

8. Environmental Science: Supports various environmental science applications, including wastewater treatment, sample preparation, and pollutant removal.

9. Nanotechnology: Aids in the preparation of nanomaterials and nanoparticles, enabling precise control over particle size and distribution.

10. Veterinary and Animal Health: Facilitates the formulation of veterinary medicines and animal health products, ensuring uniformity and effectiveness.

1. Is the processor suitable for both liquid extraction and homogenization?

Yes, it can be used for other liquid extraction, homogenization or dispersing.

2. What is cavitation, and how does it enhance liquid processing?

Cavitation is the formation and collapse of tiny bubbles in a liquid due to ultrasonic waves. These collapsing bubbles create intense shockwaves that break down particles, facilitating efficient mixing, extraction, and homogenization in liquid processing.

3. Can I customize the processor's settings for different applications?

Yes, our High Power Ultrasonic Liquid Processor offers precise control over intensity, frequency, and processing time. This enables you to tailor the settings to suit various applications and achieve optimal results.

4. What kind of maintenance does the processor require?

The processor is designed for easy maintenance. Regular cleaning of the ultrasonic probe and vessel, along with routine checks for wear and tear, ensures consistent performance. Detailed maintenance guidelines are provided in the user manual.

5. Is this processor suitable for small-scale operations?

Absolutely, our High Power Ultrasonic Liquid Processor is versatile and can be scaled to accommodate both small and large-scale operations, making it suitable for businesses of varying sizes.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.