| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

The main reason for the strengthening effect of ultrasound on extraction is the cavitation effect, that is, the tiny bubbles existing in the liquid are activated under the action of the ultrasonic field, which manifests as a series of formation/oscillation/growth/contraction and even collapse of the bubble nucleus. The kinetic process, and the physical and chemical effects caused by it, the bubble suddenly collapses within a few microseconds, and can form a local hot spot of up to 5000K or more, and the pressure can reach tens or even hundreds of MPa. With the release of high pressure, a powerful shock wave or high-speed jet is formed in the liquid. This micro-jet/shock wave produces a physical shear force on animal and plant cells and tissues, which deforms/breaks/and releases the contents, thereby promoting the dissolution of active ingredients in cells .

In order to take full advantage of ultrasonic cavitation, an ultrasonic amplitude of at least 70 microns is usually required.

At low amplitudes (below about 50 microns), cavitation strength is insufficient for most processes, including nanoparticle production (e.g., nanoemulsions, liposomes, nanocrystals), extraction, cell breakdown, depolymerization, etc.

In order to amplify the amplitude and transfer the cavitation energy to the fluid, the ultrasonic processor combines a high-gain acoustic probe.

The SPS20-1000/2000/3000 ultrasonic extractor is most commonly supplied with a 1000W/2000W/3000W ultrasonic digital generator, air cooling transducer, and full-wave horn(probe). Optional items include a flowing reactor, different shape horn, flow meter, flange and transfer pump.

| Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1600Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. High yields

2. Superior Quality

3. Full Spectrum Extracts

4. Rapid Process

5. Compatible with Any Solvent

6. Easy and Safe to Operate

7. Linear Scalability

8. Environmental-Friendly

9. Fast RoI

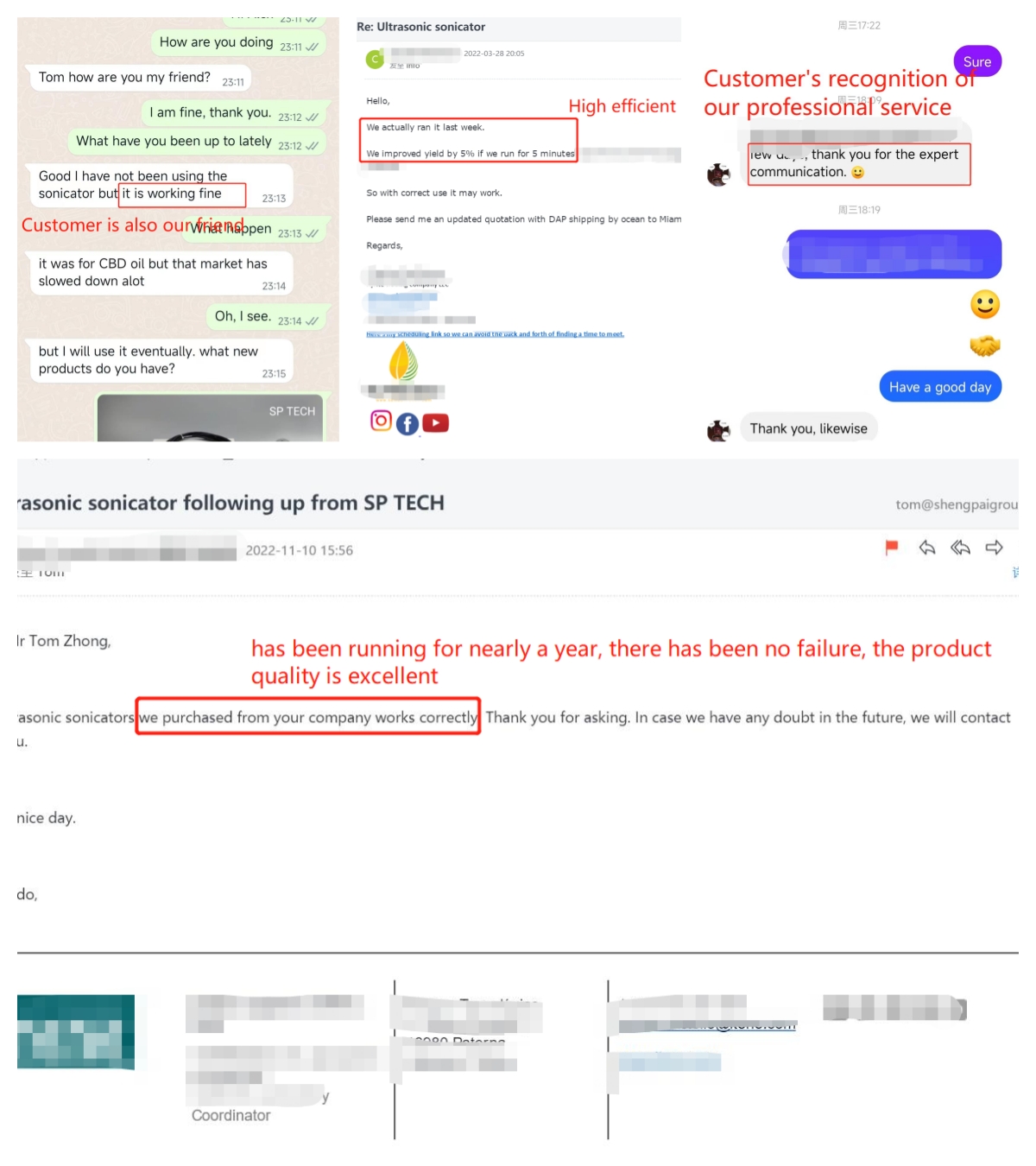

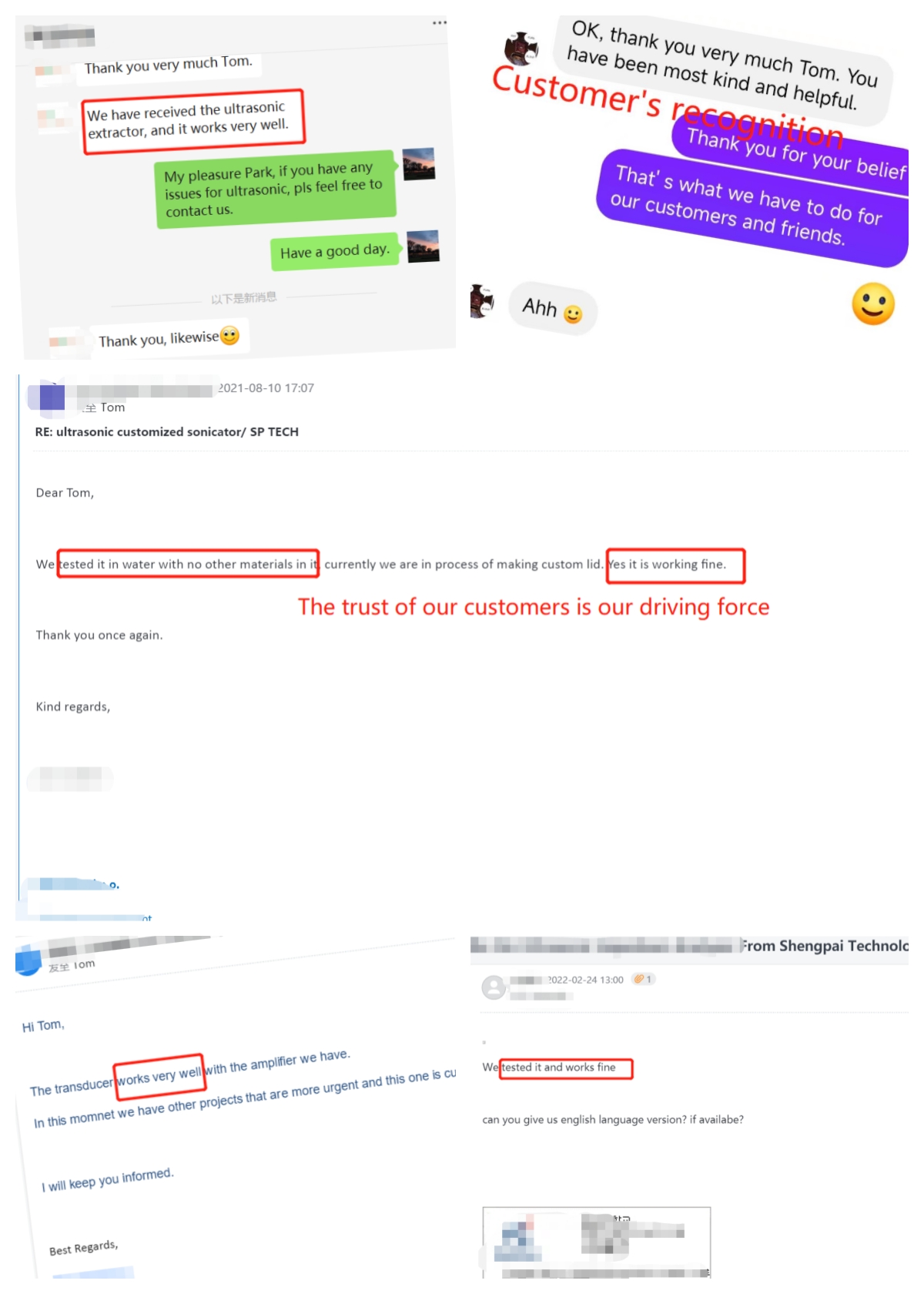

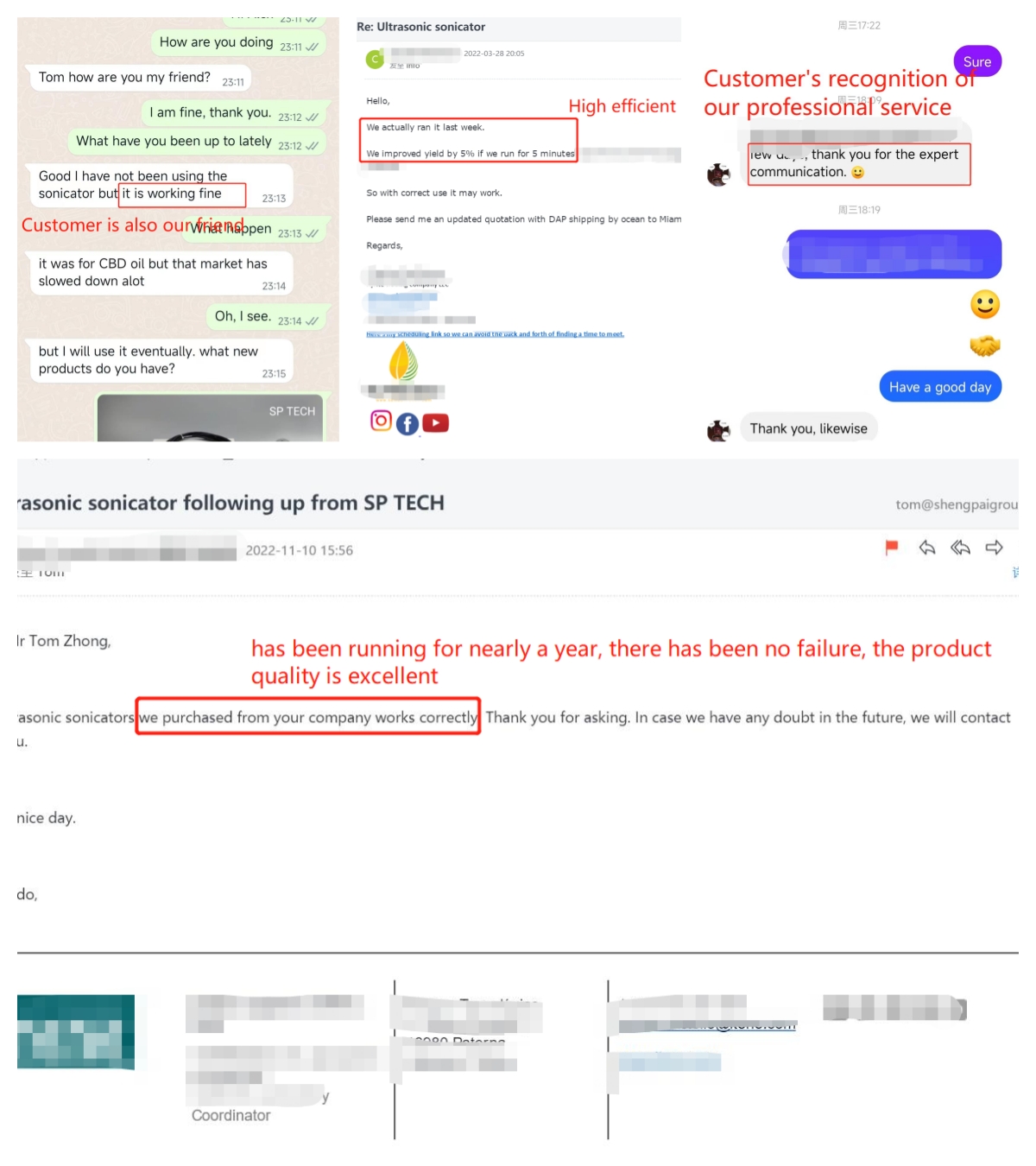

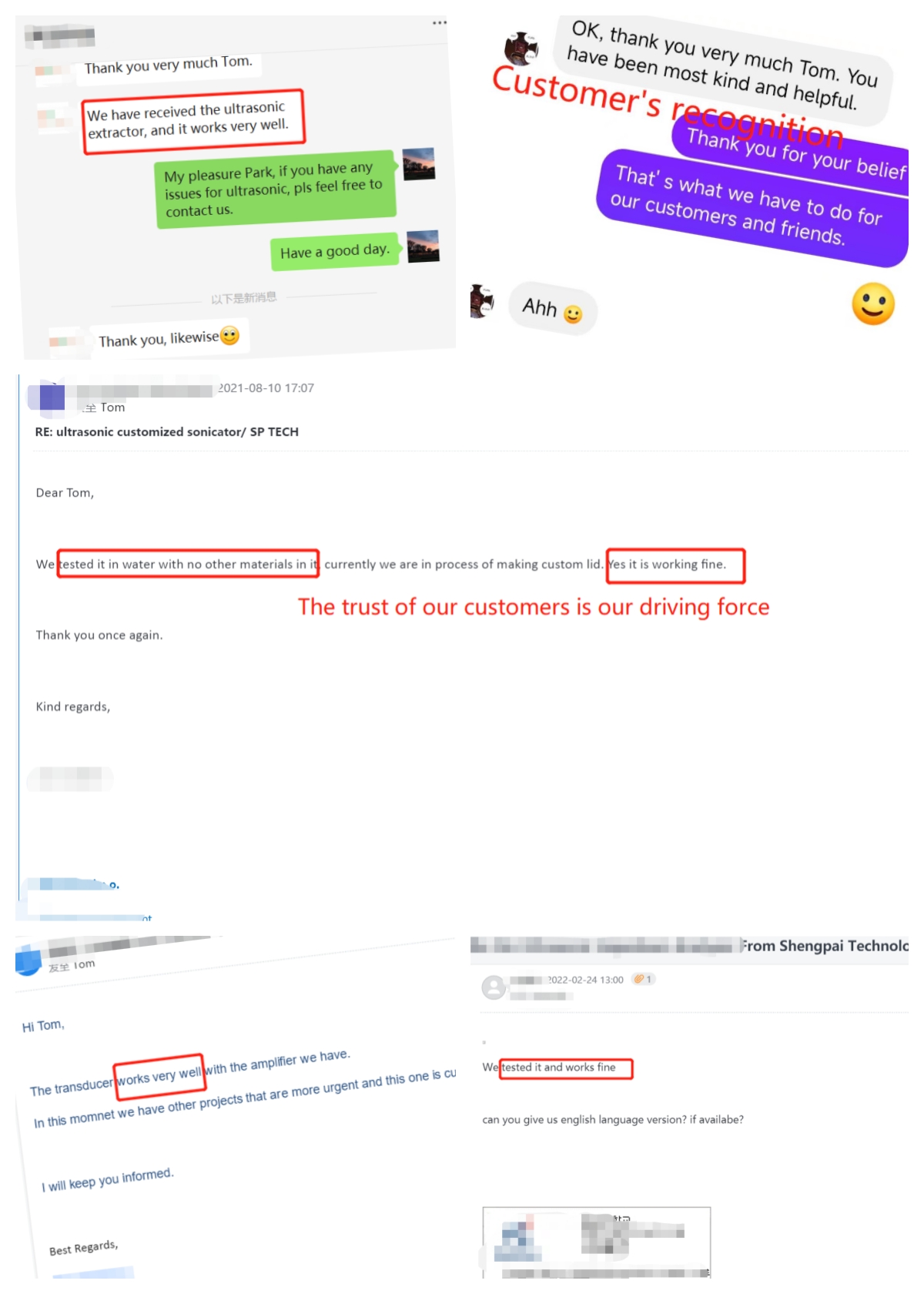

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. How does ultrasonic extraction enhance the efficiency of essential oil extraction?

Ultrasonic extraction utilizes high-frequency vibrations to break down plant cells, facilitating the release of essential oils and increasing extraction efficiency.

2. Can the Ultrasonic Sonicator be customized for different plant materials and target compounds?

Yes, our sonicator offers precise control over extraction parameters, allowing customization for various plant materials and target compounds.

3. What are the advantages of ultrasonic extraction over traditional methods?

Ultrasonic extraction offers higher extraction yields, shorter extraction times, preservation of aromatic compounds, and reduced solvent usage compared to traditional methods.

4. How does the Ultrasonic Sonicator preserve the integrity of aromatic compounds during extraction?

The sonicator's gentle yet powerful ultrasonic waves minimize thermal degradation and oxidation, preserving the integrity and aroma of extracted compounds.

5. Is the Ultrasonic Sonicator suitable for both small-scale and large-scale production?

Absolutely, our sonicator is available in various sizes and configurations, catering to both laboratory-scale research and large-scale industrial production.

6. Can the Ultrasonic Sonicator be used for the extraction of essential oils for aromatherapy?

Yes, our sonicator is highly effective in the extraction of essential oils from aromatic plants, ensuring high-quality oils for use in aromatherapy and wellness products.

7. What industries can benefit from the Ultrasonic Sonicator?

The Ultrasonic Sonicator benefits industries such as aromatherapy, cosmetics, food and beverage, pharmaceuticals, herbal medicine, flavor and fragrance, and more.

8. Does the Ultrasonic Sonicator offer pre-programmed settings for common extraction protocols?

Yes, our sonicator features pre-programmed settings for common extraction protocols, ensuring ease of use and saving valuable time.

The main reason for the strengthening effect of ultrasound on extraction is the cavitation effect, that is, the tiny bubbles existing in the liquid are activated under the action of the ultrasonic field, which manifests as a series of formation/oscillation/growth/contraction and even collapse of the bubble nucleus. The kinetic process, and the physical and chemical effects caused by it, the bubble suddenly collapses within a few microseconds, and can form a local hot spot of up to 5000K or more, and the pressure can reach tens or even hundreds of MPa. With the release of high pressure, a powerful shock wave or high-speed jet is formed in the liquid. This micro-jet/shock wave produces a physical shear force on animal and plant cells and tissues, which deforms/breaks/and releases the contents, thereby promoting the dissolution of active ingredients in cells .

In order to take full advantage of ultrasonic cavitation, an ultrasonic amplitude of at least 70 microns is usually required.

At low amplitudes (below about 50 microns), cavitation strength is insufficient for most processes, including nanoparticle production (e.g., nanoemulsions, liposomes, nanocrystals), extraction, cell breakdown, depolymerization, etc.

In order to amplify the amplitude and transfer the cavitation energy to the fluid, the ultrasonic processor combines a high-gain acoustic probe.

The SPS20-1000/2000/3000 ultrasonic extractor is most commonly supplied with a 1000W/2000W/3000W ultrasonic digital generator, air cooling transducer, and full-wave horn(probe). Optional items include a flowing reactor, different shape horn, flow meter, flange and transfer pump.

| Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1600Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. High yields

2. Superior Quality

3. Full Spectrum Extracts

4. Rapid Process

5. Compatible with Any Solvent

6. Easy and Safe to Operate

7. Linear Scalability

8. Environmental-Friendly

9. Fast RoI

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1. How does ultrasonic extraction enhance the efficiency of essential oil extraction?

Ultrasonic extraction utilizes high-frequency vibrations to break down plant cells, facilitating the release of essential oils and increasing extraction efficiency.

2. Can the Ultrasonic Sonicator be customized for different plant materials and target compounds?

Yes, our sonicator offers precise control over extraction parameters, allowing customization for various plant materials and target compounds.

3. What are the advantages of ultrasonic extraction over traditional methods?

Ultrasonic extraction offers higher extraction yields, shorter extraction times, preservation of aromatic compounds, and reduced solvent usage compared to traditional methods.

4. How does the Ultrasonic Sonicator preserve the integrity of aromatic compounds during extraction?

The sonicator's gentle yet powerful ultrasonic waves minimize thermal degradation and oxidation, preserving the integrity and aroma of extracted compounds.

5. Is the Ultrasonic Sonicator suitable for both small-scale and large-scale production?

Absolutely, our sonicator is available in various sizes and configurations, catering to both laboratory-scale research and large-scale industrial production.

6. Can the Ultrasonic Sonicator be used for the extraction of essential oils for aromatherapy?

Yes, our sonicator is highly effective in the extraction of essential oils from aromatic plants, ensuring high-quality oils for use in aromatherapy and wellness products.

7. What industries can benefit from the Ultrasonic Sonicator?

The Ultrasonic Sonicator benefits industries such as aromatherapy, cosmetics, food and beverage, pharmaceuticals, herbal medicine, flavor and fragrance, and more.

8. Does the Ultrasonic Sonicator offer pre-programmed settings for common extraction protocols?

Yes, our sonicator features pre-programmed settings for common extraction protocols, ensuring ease of use and saving valuable time.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.