| Availability: | |

|---|---|

| Quantity: | |

SP20-3000

SP

8543709990

In today's rapidly advancing technological landscape, the quest for efficiency and precision has become paramount in various industries. One such breakthrough technology revolutionizing the process of homogenization is Ultrasonic Tech. This cutting-edge technology promises to maximize efficiency, providing users with a superior experience of precision homogenization.

The Essence of Ultrasonic Tech

Ultrasonic technology utilizes high-frequency sound waves to induce mechanical vibrations, creating a homogenizing effect in various substances. This innovative approach ensures a level of precision that surpasses traditional homogenization methods.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1.Unmatched Precision:

Ultrasonic homogenization excels in providing unparalleled precision, crucial in industries where uniformity and

consistency are non-negotiable.

2.Enhanced Efficiency:

The speed at which ultrasonic tech operates is a game-changer. The rapid homogenization process significantly

reduces processing time, translating to increased overall efficiency.

3.Versatility:

Whether it's the pharmaceutical, food, or cosmetic industry, ultrasonic homogenization adapts seamlessly to

diverse applications, making it a versatile solution for various sectors.

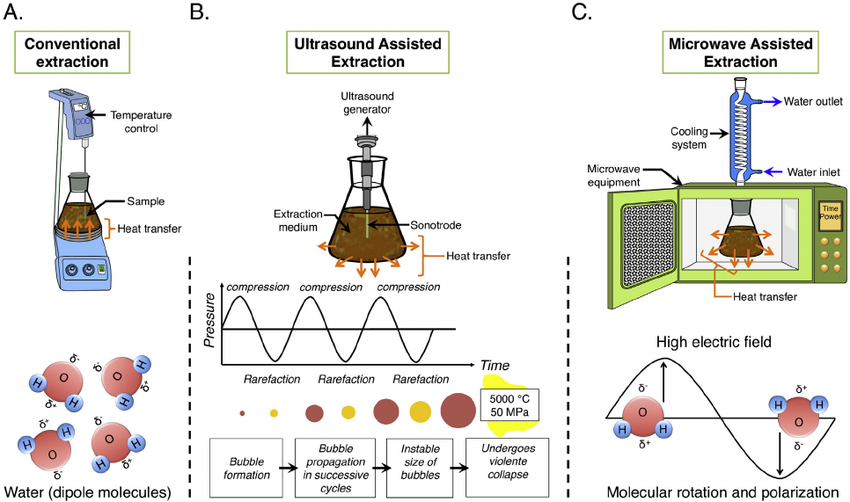

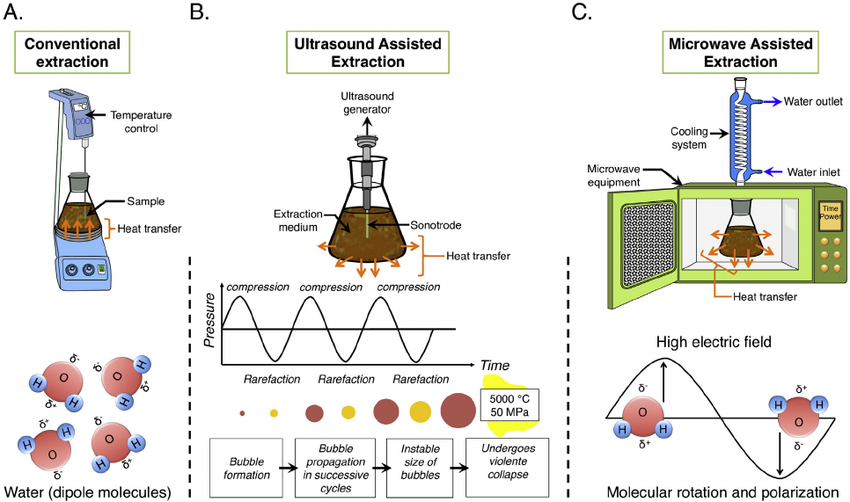

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

Let's delve into the firsthand experience of a user who integrated our Ultrasonic Tech into their homogenization process:

Li, a production manager in the pharmaceutical industry, was facing challenges with traditional homogenization methods. The need for precise particle size distribution and the demand for faster production led him to explore ultrasonic technology. After implementing our Ultrasonic Tech, Li experienced a remarkable improvement in efficiency and product quality. The results were not just satisfying but exceeded his expectations, making the switch a game-changer for his production line.

1.What is an ultrasonic homogenizer?

An ultrasonic homogenizer is a laboratory device that uses high-frequency sound waves (ultrasound) to disrupt and break down particles in a liquid sample, resulting in uniform particle size distribution and improved sample homogeneity.

2.How does an ultrasonic homogenizer work?

Ultrasonic homogenizers use acoustic cavitation, where ultrasonic waves create microscopic bubbles in a liquid. When these bubbles collapse, they generate intense shear forces and pressure, effectively homogenizing and dispersing particles in the sample.

3.What are the typical applications of ultrasonic homogenizers?

Ultrasonic homogenizers are widely used in various applications, including sample preparation for analysis, cell disruption, nanoparticle dispersion, emulsification, and the extraction of biological molecules.

4.What types of samples can be processed with an ultrasonic homogenizer?

Ultrasonic homogenizers are versatile and can be used with a range of samples, including cells, tissues, microorganisms, emulsions, and suspensions. They are particularly useful in biological and chemical research.

5.What are the advantages of using an ultrasonic homogenizer?

Key advantages include rapid and efficient homogenization, the ability to process small sample volumes, reduced heat generation (suitable for heat-sensitive samples), and the versatility to handle various sample types.

6.Are there limitations to using ultrasonic homogenizers?

While ultrasonic homogenizers are effective for many applications, they may not be suitable for certain hard or dense materials. Additionally, the process can introduce heat, so consideration is needed for temperature-sensitive samples.

7. Could we as your agent?

Of course. We are looking for sole agent in Country who have the willing to cooperate with us for long business term.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

In today's rapidly advancing technological landscape, the quest for efficiency and precision has become paramount in various industries. One such breakthrough technology revolutionizing the process of homogenization is Ultrasonic Tech. This cutting-edge technology promises to maximize efficiency, providing users with a superior experience of precision homogenization.

The Essence of Ultrasonic Tech

Ultrasonic technology utilizes high-frequency sound waves to induce mechanical vibrations, creating a homogenizing effect in various substances. This innovative approach ensures a level of precision that surpasses traditional homogenization methods.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1.Unmatched Precision:

Ultrasonic homogenization excels in providing unparalleled precision, crucial in industries where uniformity and

consistency are non-negotiable.

2.Enhanced Efficiency:

The speed at which ultrasonic tech operates is a game-changer. The rapid homogenization process significantly

reduces processing time, translating to increased overall efficiency.

3.Versatility:

Whether it's the pharmaceutical, food, or cosmetic industry, ultrasonic homogenization adapts seamlessly to

diverse applications, making it a versatile solution for various sectors.

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

Let's delve into the firsthand experience of a user who integrated our Ultrasonic Tech into their homogenization process:

Li, a production manager in the pharmaceutical industry, was facing challenges with traditional homogenization methods. The need for precise particle size distribution and the demand for faster production led him to explore ultrasonic technology. After implementing our Ultrasonic Tech, Li experienced a remarkable improvement in efficiency and product quality. The results were not just satisfying but exceeded his expectations, making the switch a game-changer for his production line.

1.What is an ultrasonic homogenizer?

An ultrasonic homogenizer is a laboratory device that uses high-frequency sound waves (ultrasound) to disrupt and break down particles in a liquid sample, resulting in uniform particle size distribution and improved sample homogeneity.

2.How does an ultrasonic homogenizer work?

Ultrasonic homogenizers use acoustic cavitation, where ultrasonic waves create microscopic bubbles in a liquid. When these bubbles collapse, they generate intense shear forces and pressure, effectively homogenizing and dispersing particles in the sample.

3.What are the typical applications of ultrasonic homogenizers?

Ultrasonic homogenizers are widely used in various applications, including sample preparation for analysis, cell disruption, nanoparticle dispersion, emulsification, and the extraction of biological molecules.

4.What types of samples can be processed with an ultrasonic homogenizer?

Ultrasonic homogenizers are versatile and can be used with a range of samples, including cells, tissues, microorganisms, emulsions, and suspensions. They are particularly useful in biological and chemical research.

5.What are the advantages of using an ultrasonic homogenizer?

Key advantages include rapid and efficient homogenization, the ability to process small sample volumes, reduced heat generation (suitable for heat-sensitive samples), and the versatility to handle various sample types.

6.Are there limitations to using ultrasonic homogenizers?

While ultrasonic homogenizers are effective for many applications, they may not be suitable for certain hard or dense materials. Additionally, the process can introduce heat, so consideration is needed for temperature-sensitive samples.

7. Could we as your agent?

Of course. We are looking for sole agent in Country who have the willing to cooperate with us for long business term.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.