| Availability: | |

|---|---|

| Quantity: | |

SP20-1000

SP

8543709990

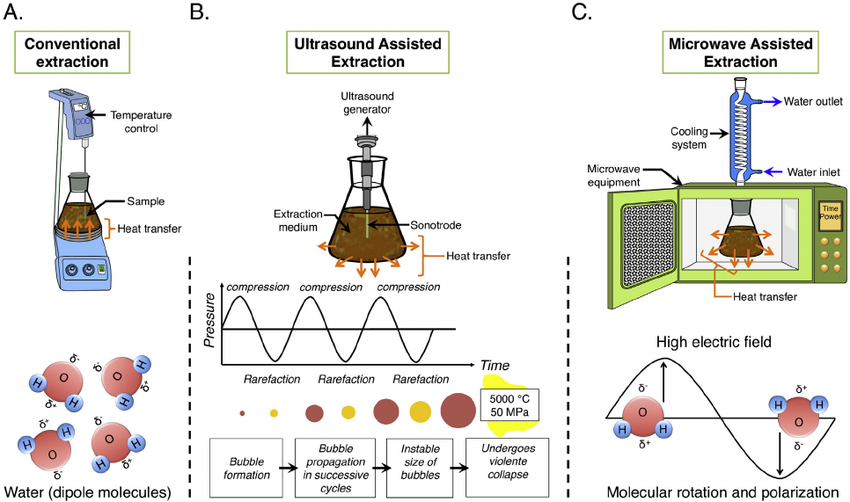

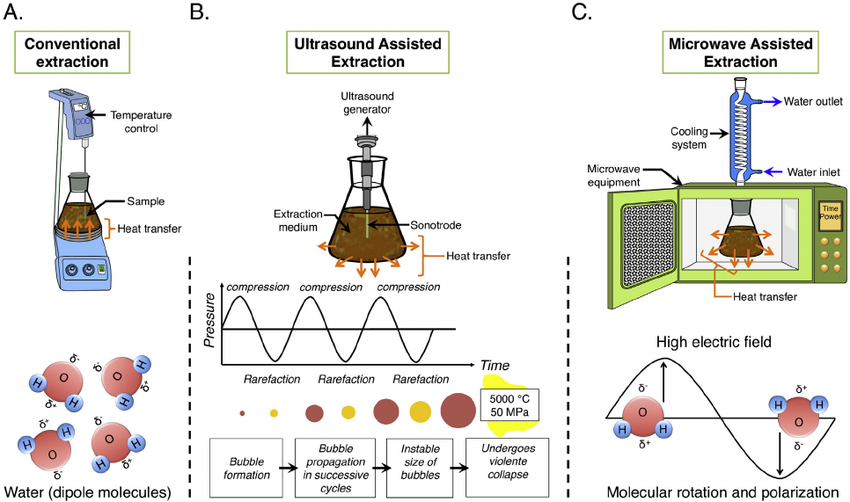

Cavitation Effect:

Ultrasonic homogenizers generate cavitation, creating microbubbles in the liquid. When these bubbles collapse, they produce intense shock waves, effectively breaking down particles and promoting emulsification.

Particle Size Reduction:

The high shear forces generated by ultrasonic waves lead to the reduction of droplet or particle size in the emulsion. This is crucial for achieving a stable and uniform mixture.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Versatility:

Ultrasonic homogenizers find applications in various industries, including food and beverage, pharmaceuticals, cosmetics, and biotechnology. They are used for creating stable emulsions, dispersing nano-sized particles, and enhancing reaction kinetics.

Process Efficiency:

Compared to traditional methods, ultrasonic emulsification is often more efficient and requires shorter processing times. This can contribute to increased productivity and cost-effectiveness.

Controlled Parameters:

Modern ultrasonic homogenizers allow precise control over parameters such as amplitude, frequency, and processing time. This control ensures customization according to specific emulsification requirements.

Laboratory and Industrial Models:

Ultrasonic homogenizers come in various sizes, ranging from laboratory-scale devices for research purposes to larger industrial models suitable for large-scale production.

Safety Considerations:

While ultrasonic homogenization is generally safe, proper safety measures should be followed to protect operators from exposure to high-intensity ultrasound. This includes using appropriate protective gear and ensuring proper equipment maintenance.

In summary, ultrasonic homogenizers play a crucial role in achieving efficient and consistent emulsification of water and oil in diverse industrial applications. Their ability to reduce particle size, improve process efficiency, and offer precise control makes them valuable tools in research and production settings.

|  |  |

Ultrasonic emulsification equipment works very well.

Since we added ultrasonic oil-water emulsification equipment and replaced our oil-water emulsification pump, our emulsification efficiency has improved a lot, and we have saved a lot of catalysts and costs.

You are very friendly and helpful. Thanks to the experts for the exchange.

Customer recognition and trust are our motivation.

Valvoline Technology takes "customer service first" as its corporate culture. The purpose is "quality first, service first". Today, Shengpai Technology has earned a very good reputation with its rich professional knowledge and good after-sales service.

1. Do you have it in stock?

We only have common products in stock but not for the nonstandard products.Because all the products need make based on customers' different requirements.

2. Could you advise to us the design based on our special requirements or based on our object samples?

Of course, we can do. Please tell us your idea or your application.

If you have sample object, send it to us or send detail pictures.

3.How long do you make the order product?

Common products for 7days, big qty and none standard products for 20days.

4. Do you have operating manual?

Of course, we will put it with the goods together.

5. How about the quality?

We have export to many other customers from all over the world, the feed back is good,quality is the first of our company.

6. Could you do OEM?

Yes, of course. We can produce according customers' requirement, just send us your requirements and design of drawing and sample.

7. Could we as your agent?

Of course. We are looking for sole agent in Country who have the willing to cooperate with us for long business term.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

Cavitation Effect:

Ultrasonic homogenizers generate cavitation, creating microbubbles in the liquid. When these bubbles collapse, they produce intense shock waves, effectively breaking down particles and promoting emulsification.

Particle Size Reduction:

The high shear forces generated by ultrasonic waves lead to the reduction of droplet or particle size in the emulsion. This is crucial for achieving a stable and uniform mixture.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Versatility:

Ultrasonic homogenizers find applications in various industries, including food and beverage, pharmaceuticals, cosmetics, and biotechnology. They are used for creating stable emulsions, dispersing nano-sized particles, and enhancing reaction kinetics.

Process Efficiency:

Compared to traditional methods, ultrasonic emulsification is often more efficient and requires shorter processing times. This can contribute to increased productivity and cost-effectiveness.

Controlled Parameters:

Modern ultrasonic homogenizers allow precise control over parameters such as amplitude, frequency, and processing time. This control ensures customization according to specific emulsification requirements.

Laboratory and Industrial Models:

Ultrasonic homogenizers come in various sizes, ranging from laboratory-scale devices for research purposes to larger industrial models suitable for large-scale production.

Safety Considerations:

While ultrasonic homogenization is generally safe, proper safety measures should be followed to protect operators from exposure to high-intensity ultrasound. This includes using appropriate protective gear and ensuring proper equipment maintenance.

In summary, ultrasonic homogenizers play a crucial role in achieving efficient and consistent emulsification of water and oil in diverse industrial applications. Their ability to reduce particle size, improve process efficiency, and offer precise control makes them valuable tools in research and production settings.

|  |  |

Ultrasonic emulsification equipment works very well.

Since we added ultrasonic oil-water emulsification equipment and replaced our oil-water emulsification pump, our emulsification efficiency has improved a lot, and we have saved a lot of catalysts and costs.

You are very friendly and helpful. Thanks to the experts for the exchange.

Customer recognition and trust are our motivation.

Valvoline Technology takes "customer service first" as its corporate culture. The purpose is "quality first, service first". Today, Shengpai Technology has earned a very good reputation with its rich professional knowledge and good after-sales service.

1. Do you have it in stock?

We only have common products in stock but not for the nonstandard products.Because all the products need make based on customers' different requirements.

2. Could you advise to us the design based on our special requirements or based on our object samples?

Of course, we can do. Please tell us your idea or your application.

If you have sample object, send it to us or send detail pictures.

3.How long do you make the order product?

Common products for 7days, big qty and none standard products for 20days.

4. Do you have operating manual?

Of course, we will put it with the goods together.

5. How about the quality?

We have export to many other customers from all over the world, the feed back is good,quality is the first of our company.

6. Could you do OEM?

Yes, of course. We can produce according customers' requirement, just send us your requirements and design of drawing and sample.

7. Could we as your agent?

Of course. We are looking for sole agent in Country who have the willing to cooperate with us for long business term.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.