| Availability: | |

|---|---|

| Quantity: | |

SPS20-2000/ 3000Z

SP

8543709990

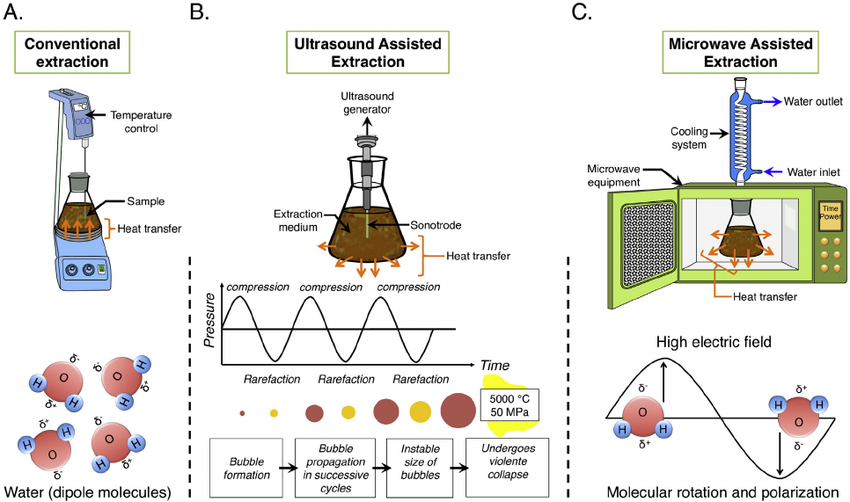

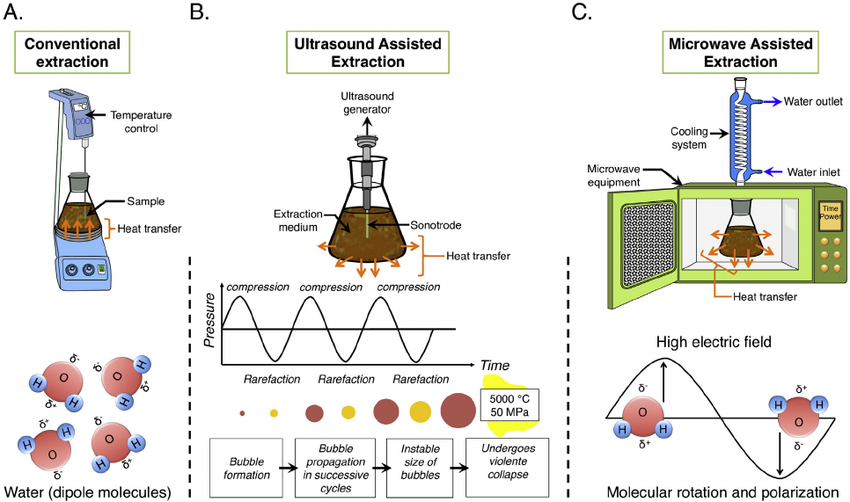

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples. This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples. This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

The process involves placing the sample in a solvent and subjecting it to ultrasonic waves. The waves cause cavitation, which produces small bubbles that implode, generating high pressures and temperatures that break down the cell walls and release the desired compounds into the solvent.

Ultrasonic extractors are based on ultrasonic transducers that generate rapid mechanical vibration waves. Ultrasonic energy is used to improve the uniformity of ultrasonic action and increase the sound intensity, making the surface layer of particles too thin, causing the surface to fall off, the particles to break, and the outer walls of cells to be crushed by ultrasonic waves. For extra virgin olive oil, olives are ground into a paste SPtech ultrasonic equipment improves the quality and the quantity of the extra virgin olive oil that is extracted.This is done by passing the paste through one or more 2 or 3 kilowatt ultrasonic reactors. This is a non-thermal in-line process.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1.Adopt intelligent control technology to achieve stable amplitude output of ultrasonic amplitude, ensuring uniform and stable cavitation effect.

2.Adopt automatic frequency matching mode to ensure that the ultrasonic transducer works at the best time every time.

3.The system has two working modes, continuous and intermittent.

4.The system can set the ultrasonic working time independently and facilitate the experimental analysis.

5.The system uses a focused design,that have high energy density, which significantly improves the efficiency of the experiment.

6.The system has a variety of protection mechanisms to ensure stable operation and long life.

7.The system uses a 5V fan,that have high safety factor.

Customer reviews are as follows:

Ultrasonic homogenizers work very well.

Through production comparison, after adding the ultrasonic extractor and working for 60 minutes, the production increased by 8%.

Ultrasonic generators are excellent tools for cell disruption and sample preparation. It's easy to use and produces consistent results. I would highly recommend it.

An ultrasonic generator is a powerful tool, but it can be tricky to use. It took me some trial and error to get the setup right, but once I did it worked perfectly.

You are very kind and helpful. Thank you for your expert exchange.

Customer recognition and trust are our motivation.

Valvoline Technology takes "customer service first" as its corporate culture. The purpose is "quality first, service first". Today, Valvoline Technology has earned a very good reputation due to its rich professional knowledge and good after-sales service.

1.What is cavitation, and how does it enhance liquid processing?

Cavitation is the formation and collapse of tiny bubbles in a liquid due to ultrasonic waves. These collapsing bubbles create intense shockwaves that break down particles, facilitating efficient mixing, extraction, and homogenization in liquid processing.

2.What is ultrasonic extraction?

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples. This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

3.What are the applications of ultrasonic homogenizers?

The ultrasonic homogenizer is mainly used for tissue dispersion in biotechnology, sample preparation in pharmaceutical field, enzyme treatment in food industry, detection of pesticide residues in food and veterinary drug residues, as well as in pharmaceutical industry, cosmetics industry, paint industry and petrochemical industry.

4.What is the application of ultrasonic homogenizer in the food field?

In milk in the natural state, the diameter of the fat globules is uneven, ranging from 1 to 10 μm, generally 2 to 5 μm. These fat globules float on the surface of the milk due to the buoyancy force to form a layer of cream, which makes the milk stratified. . The presence of these fat globules greatly affects the appearance and taste of milk and dairy products. If the milk is homogenized, the diameter of the fat globules can be controlled at about 2 μm. At this time, the surface area of milk fat increases and the buoyancy decreases, thereby avoiding stratification and achieving the effect of homogenization.

The unique effect of ultrasonic homogenizer improves the quality of the product in terms of appearance and taste.

5.How does the processor contribute to sustainable practices?

The processor's energy-efficient design minimizes power consumption, reducing its environmental footprint. Additionally, its rapid processing capability leads to reduced waste generation, aligning with sustainable manufacturing practices.

6.Can it be used for nanoemulsion production?

Absolutely, the High Power Ultrasonic Liquid Processor is adept at producing nanoemulsions. Its precise control and powerful cavitation enable the creation of stable nano-sized droplets, crucial for nanoemulsion formulation.

7.What technical support and training do you provide?

We offer comprehensive technical support, including installation guidance, operational training, and troubleshooting assistance. Our team is dedicated to ensuring a seamless experience with the processor.

8.Are there any successful case studies using this processor in CBD extraction?

Yes, we have numerous success stories showcasing the processor's effectiveness in CBD extraction. These case studies demonstrate improved yields, shortened processing times, and enhanced product quality across various CBD extraction processes.

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples. This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples. This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

The process involves placing the sample in a solvent and subjecting it to ultrasonic waves. The waves cause cavitation, which produces small bubbles that implode, generating high pressures and temperatures that break down the cell walls and release the desired compounds into the solvent.

Ultrasonic extractors are based on ultrasonic transducers that generate rapid mechanical vibration waves. Ultrasonic energy is used to improve the uniformity of ultrasonic action and increase the sound intensity, making the surface layer of particles too thin, causing the surface to fall off, the particles to break, and the outer walls of cells to be crushed by ultrasonic waves. For extra virgin olive oil, olives are ground into a paste SPtech ultrasonic equipment improves the quality and the quantity of the extra virgin olive oil that is extracted.This is done by passing the paste through one or more 2 or 3 kilowatt ultrasonic reactors. This is a non-thermal in-line process.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1.Adopt intelligent control technology to achieve stable amplitude output of ultrasonic amplitude, ensuring uniform and stable cavitation effect.

2.Adopt automatic frequency matching mode to ensure that the ultrasonic transducer works at the best time every time.

3.The system has two working modes, continuous and intermittent.

4.The system can set the ultrasonic working time independently and facilitate the experimental analysis.

5.The system uses a focused design,that have high energy density, which significantly improves the efficiency of the experiment.

6.The system has a variety of protection mechanisms to ensure stable operation and long life.

7.The system uses a 5V fan,that have high safety factor.

Customer reviews are as follows:

Ultrasonic homogenizers work very well.

Through production comparison, after adding the ultrasonic extractor and working for 60 minutes, the production increased by 8%.

Ultrasonic generators are excellent tools for cell disruption and sample preparation. It's easy to use and produces consistent results. I would highly recommend it.

An ultrasonic generator is a powerful tool, but it can be tricky to use. It took me some trial and error to get the setup right, but once I did it worked perfectly.

You are very kind and helpful. Thank you for your expert exchange.

Customer recognition and trust are our motivation.

Valvoline Technology takes "customer service first" as its corporate culture. The purpose is "quality first, service first". Today, Valvoline Technology has earned a very good reputation due to its rich professional knowledge and good after-sales service.

1.What is cavitation, and how does it enhance liquid processing?

Cavitation is the formation and collapse of tiny bubbles in a liquid due to ultrasonic waves. These collapsing bubbles create intense shockwaves that break down particles, facilitating efficient mixing, extraction, and homogenization in liquid processing.

2.What is ultrasonic extraction?

Ultrasonic extraction is a process of using high-frequency sound waves to extract compounds from solid or liquid samples. This technique is often used in the fields of chemistry, food science, and biotechnology to extract bioactive compounds from natural products, such as plants, fruits, and vegetables.

3.What are the applications of ultrasonic homogenizers?

The ultrasonic homogenizer is mainly used for tissue dispersion in biotechnology, sample preparation in pharmaceutical field, enzyme treatment in food industry, detection of pesticide residues in food and veterinary drug residues, as well as in pharmaceutical industry, cosmetics industry, paint industry and petrochemical industry.

4.What is the application of ultrasonic homogenizer in the food field?

In milk in the natural state, the diameter of the fat globules is uneven, ranging from 1 to 10 μm, generally 2 to 5 μm. These fat globules float on the surface of the milk due to the buoyancy force to form a layer of cream, which makes the milk stratified. . The presence of these fat globules greatly affects the appearance and taste of milk and dairy products. If the milk is homogenized, the diameter of the fat globules can be controlled at about 2 μm. At this time, the surface area of milk fat increases and the buoyancy decreases, thereby avoiding stratification and achieving the effect of homogenization.

The unique effect of ultrasonic homogenizer improves the quality of the product in terms of appearance and taste.

5.How does the processor contribute to sustainable practices?

The processor's energy-efficient design minimizes power consumption, reducing its environmental footprint. Additionally, its rapid processing capability leads to reduced waste generation, aligning with sustainable manufacturing practices.

6.Can it be used for nanoemulsion production?

Absolutely, the High Power Ultrasonic Liquid Processor is adept at producing nanoemulsions. Its precise control and powerful cavitation enable the creation of stable nano-sized droplets, crucial for nanoemulsion formulation.

7.What technical support and training do you provide?

We offer comprehensive technical support, including installation guidance, operational training, and troubleshooting assistance. Our team is dedicated to ensuring a seamless experience with the processor.

8.Are there any successful case studies using this processor in CBD extraction?

Yes, we have numerous success stories showcasing the processor's effectiveness in CBD extraction. These case studies demonstrate improved yields, shortened processing times, and enhanced product quality across various CBD extraction processes.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.