| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000S

SP

8543709990

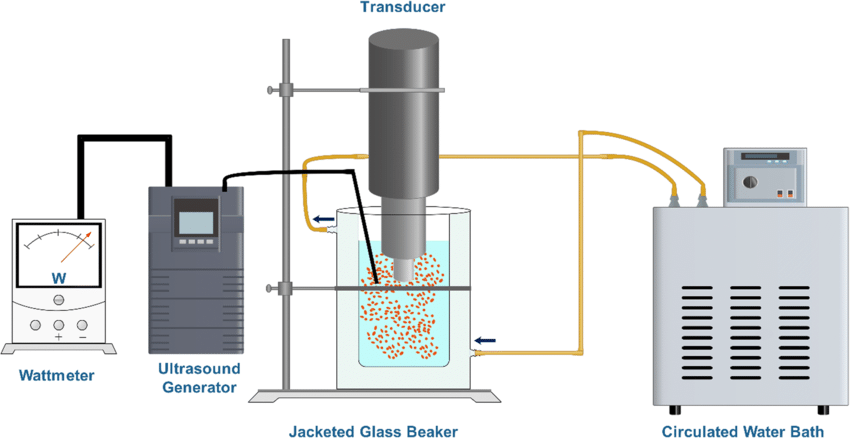

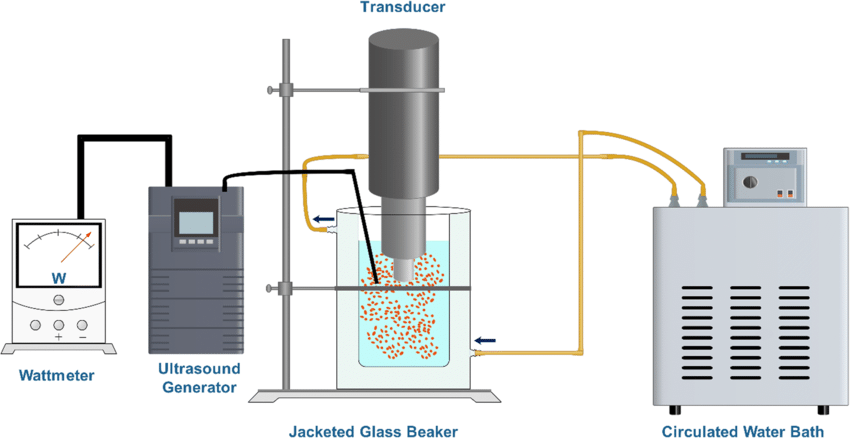

Ultrasonic extraction is achieved when high-power, low-frequency ultrasound waves are coupled into a slurry consisting of botanical material in a solvent. High-power ultrasonic waves are coupled via a probe-type ultrasonic processor into the slurry. highly energetic ultrasound waves travel through the liquid creating alternating high-pressure / low-pressure cycles, which results in the phenomenon of acoustic cavitation. Acoustic or ultrasonic cavitation leads locally to extreme temperatures, pressures, heating/cooling rates, pressure differentials and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues etc.), micro-jets and interparticlular collision generate effects such as surface peeling, erosion, particle breakdown, sonoporation (the perforation of cell walls and cell membranes) and cell disruption.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500W | 1000W | 1000W | 2000W | 3000W | 3000W |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | 35MPa | 35MPa | 35MPa |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Food processing Reaction Acceleration - cavitation accelerates chemical and physical reactions.Fine Particle Dispersion - e.g. nanoparticle processing Disruption and Cell Lysing - will break open biological tissues and Cells to extract enzymes and DNA, prepare vaccines.Homogenization - making uniform mixtures of liquids or liquid suspensions.Emulsification - processing foods, pharmaceuticals, and cosmetics.Dissolution - dissolving solids in solvents.Degassing - removing gases from solutions without heat or vacuum.Inline pipe cleaning, removes scale or build/up without disassembly.Cylindrical 360° internally radiating chamber.

Food processing Reaction Acceleration - cavitation accelerates chemical and physical reactions.Fine Particle Dispersion - e.g. nanoparticle processing Disruption and Cell Lysing - will break open biological tissues and Cells to extract enzymes and DNA, prepare vaccines.Homogenization - making uniform mixtures of liquids or liquid suspensions.Emulsification - processing foods, pharmaceuticals, and cosmetics.Dissolution - dissolving solids in solvents.Degassing - removing gases from solutions without heat or vacuum.Inline pipe cleaning, removes scale or build/up without disassembly.Cylindrical 360° internally radiating chamber.

1. The core components of our products are made of titanium

2. There are different sizes and types of ultrasonic horns (probes) to choose from

3. Ours is a digitally controlled generator. You don’t need to operate it yourself after the product is connected. It can automatically tune and automatically search for frequencies.

4. The digitally controlled generator has automatic alarm protection and is easy to operate.

5. Power adjustable from 1% to 99%

6. The ultrasonic amplitude is stable, the working time is long, and the radiation area is 2.5 times larger than traditional tools.

7. High amplitude allows ultrasonic cavitation intensity to handle liquids more effectively

8. Provide consulting services and customized reactor design

9. Custom sizes available for laboratory and high-volume industrial applications

|  |  |

Customers' evalution as follow:

The ultrasonic homogenizer works very well.

Using ultrasonic waves to extract caffeine, the purity of the extracted raw solution is 20% higher than that extracted using chemical agents, and the yield is increased by 10% than before.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1.What is cavitation, and how does it enhance liquid processing?

Cavitation is the formation and collapse of tiny bubbles in a liquid due to ultrasonic waves. These collapsing bubbles create intense shockwaves that break down particles, facilitating efficient mixing, extraction, and homogenization in liquid processing.

2.Can I customize the processor's settings for different applications?

Yes, our High Power Ultrasonic Liquid Processor offers precise control over intensity, frequency, and processing time. This enables you to tailor the settings to suit various applications and achieve optimal results.

3.What kind of maintenance does the processor require?

The processor is designed for easy maintenance. Regular cleaning of the ultrasonic probe and vessel, along with routine checks for wear and tear, ensures consistent performance. Detailed maintenance guidelines are provided in the user manual.

4.Is this processor suitable for small-scale operations?

Absolutely, our High Power Ultrasonic Liquid Processor is versatile and can be scaled to accommodate both small and large-scale operations, making it suitable for businesses of varying sizes.

5.What is the lifespan of the High Power Ultrasonic Liquid Processor?

With its robust construction and quality materials, the processor is engineered for durability and can serve reliably for many years. Proper maintenance and care further extend its operational lifespan.

6.Does the processor come with safety features?

Yes, safety is paramount. Our processor is equipped with multiple safety mechanisms, including overheating protection, voltage stabilization, and automatic shutdown in case of anomalies, ensuring secure operation.

7.How does the processor contribute to sustainable practices?

The processor's energy-efficient design minimizes power consumption, reducing its environmental footprint. Additionally, its rapid processing capability leads to reduced waste generation, aligning with sustainable manufacturing practices.

8.Can it be used for nanoemulsion production?

Absolutely, the High Power Ultrasonic Liquid Processor is adept at producing nanoemulsions. Its precise control and powerful cavitation enable the creation of stable nano-sized droplets, crucial for nanoemulsion formulation.

9.What technical support and training do you provide?

We offer comprehensive technical support, including installation guidance, operational training, and troubleshooting assistance. Our team is dedicated to ensuring a seamless experience with the processor.

10.Are there any successful case studies using this processor in CBD extraction?

Yes, we have numerous success stories showcasing the processor's effectiveness in CBD extraction. These case studies demonstrate improved yields, shortened processing times, and enhanced product quality across various CBD extraction processes.

Experience the future of ultrasonic liquid processing with our High Power Ultrasonic Liquid Processor. Unleash its high-power potential at a low cost and elevate your production capabilities across industries

Ultrasonic extraction is achieved when high-power, low-frequency ultrasound waves are coupled into a slurry consisting of botanical material in a solvent. High-power ultrasonic waves are coupled via a probe-type ultrasonic processor into the slurry. highly energetic ultrasound waves travel through the liquid creating alternating high-pressure / low-pressure cycles, which results in the phenomenon of acoustic cavitation. Acoustic or ultrasonic cavitation leads locally to extreme temperatures, pressures, heating/cooling rates, pressure differentials and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues etc.), micro-jets and interparticlular collision generate effects such as surface peeling, erosion, particle breakdown, sonoporation (the perforation of cell walls and cell membranes) and cell disruption.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500W | 1000W | 1000W | 2000W | 3000W | 3000W |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | 35MPa | 35MPa | 35MPa |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Food processing Reaction Acceleration - cavitation accelerates chemical and physical reactions.Fine Particle Dispersion - e.g. nanoparticle processing Disruption and Cell Lysing - will break open biological tissues and Cells to extract enzymes and DNA, prepare vaccines.Homogenization - making uniform mixtures of liquids or liquid suspensions.Emulsification - processing foods, pharmaceuticals, and cosmetics.Dissolution - dissolving solids in solvents.Degassing - removing gases from solutions without heat or vacuum.Inline pipe cleaning, removes scale or build/up without disassembly.Cylindrical 360° internally radiating chamber.

Food processing Reaction Acceleration - cavitation accelerates chemical and physical reactions.Fine Particle Dispersion - e.g. nanoparticle processing Disruption and Cell Lysing - will break open biological tissues and Cells to extract enzymes and DNA, prepare vaccines.Homogenization - making uniform mixtures of liquids or liquid suspensions.Emulsification - processing foods, pharmaceuticals, and cosmetics.Dissolution - dissolving solids in solvents.Degassing - removing gases from solutions without heat or vacuum.Inline pipe cleaning, removes scale or build/up without disassembly.Cylindrical 360° internally radiating chamber.

1. The core components of our products are made of titanium

2. There are different sizes and types of ultrasonic horns (probes) to choose from

3. Ours is a digitally controlled generator. You don’t need to operate it yourself after the product is connected. It can automatically tune and automatically search for frequencies.

4. The digitally controlled generator has automatic alarm protection and is easy to operate.

5. Power adjustable from 1% to 99%

6. The ultrasonic amplitude is stable, the working time is long, and the radiation area is 2.5 times larger than traditional tools.

7. High amplitude allows ultrasonic cavitation intensity to handle liquids more effectively

8. Provide consulting services and customized reactor design

9. Custom sizes available for laboratory and high-volume industrial applications

|  |  |

Customers' evalution as follow:

The ultrasonic homogenizer works very well.

Using ultrasonic waves to extract caffeine, the purity of the extracted raw solution is 20% higher than that extracted using chemical agents, and the yield is increased by 10% than before.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

1.What is cavitation, and how does it enhance liquid processing?

Cavitation is the formation and collapse of tiny bubbles in a liquid due to ultrasonic waves. These collapsing bubbles create intense shockwaves that break down particles, facilitating efficient mixing, extraction, and homogenization in liquid processing.

2.Can I customize the processor's settings for different applications?

Yes, our High Power Ultrasonic Liquid Processor offers precise control over intensity, frequency, and processing time. This enables you to tailor the settings to suit various applications and achieve optimal results.

3.What kind of maintenance does the processor require?

The processor is designed for easy maintenance. Regular cleaning of the ultrasonic probe and vessel, along with routine checks for wear and tear, ensures consistent performance. Detailed maintenance guidelines are provided in the user manual.

4.Is this processor suitable for small-scale operations?

Absolutely, our High Power Ultrasonic Liquid Processor is versatile and can be scaled to accommodate both small and large-scale operations, making it suitable for businesses of varying sizes.

5.What is the lifespan of the High Power Ultrasonic Liquid Processor?

With its robust construction and quality materials, the processor is engineered for durability and can serve reliably for many years. Proper maintenance and care further extend its operational lifespan.

6.Does the processor come with safety features?

Yes, safety is paramount. Our processor is equipped with multiple safety mechanisms, including overheating protection, voltage stabilization, and automatic shutdown in case of anomalies, ensuring secure operation.

7.How does the processor contribute to sustainable practices?

The processor's energy-efficient design minimizes power consumption, reducing its environmental footprint. Additionally, its rapid processing capability leads to reduced waste generation, aligning with sustainable manufacturing practices.

8.Can it be used for nanoemulsion production?

Absolutely, the High Power Ultrasonic Liquid Processor is adept at producing nanoemulsions. Its precise control and powerful cavitation enable the creation of stable nano-sized droplets, crucial for nanoemulsion formulation.

9.What technical support and training do you provide?

We offer comprehensive technical support, including installation guidance, operational training, and troubleshooting assistance. Our team is dedicated to ensuring a seamless experience with the processor.

10.Are there any successful case studies using this processor in CBD extraction?

Yes, we have numerous success stories showcasing the processor's effectiveness in CBD extraction. These case studies demonstrate improved yields, shortened processing times, and enhanced product quality across various CBD extraction processes.

Experience the future of ultrasonic liquid processing with our High Power Ultrasonic Liquid Processor. Unleash its high-power potential at a low cost and elevate your production capabilities across industries

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.