| Availability: | |

|---|---|

| Quantity: | |

SP20-3000

SP

8543709990

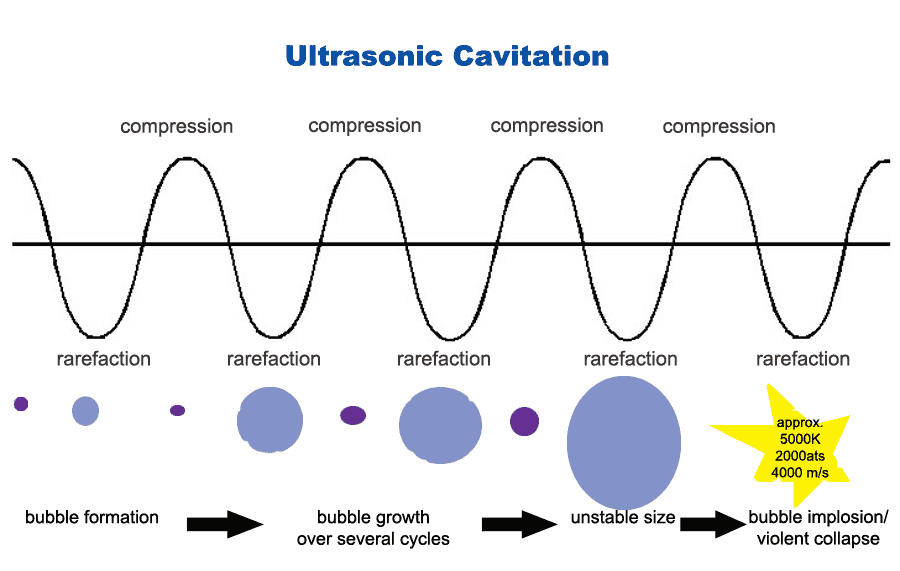

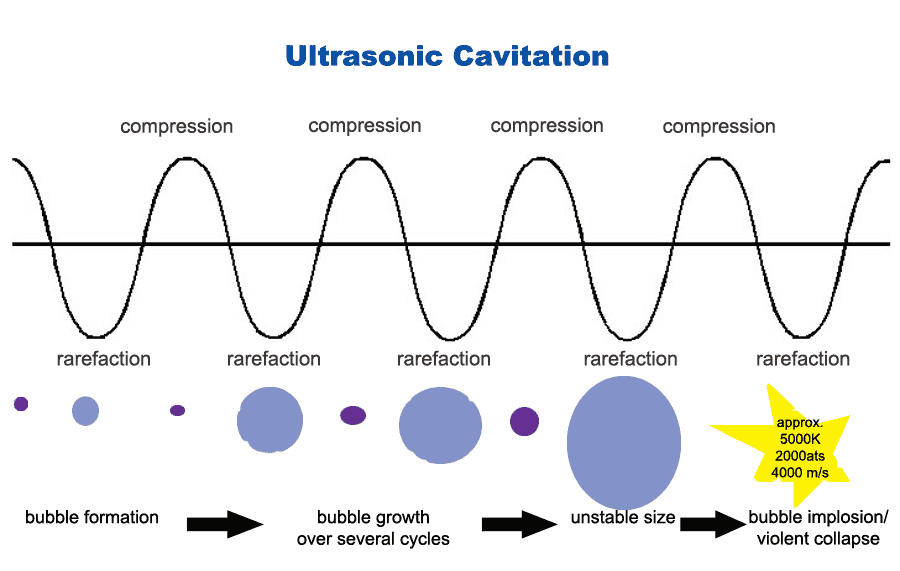

The ultrasonic liquid processor consists of a probe and a power source. The processor is also haptic. When a liquid is treated with high-intensity ultrasound, the sound waves propagating into the liquid medium create alternating cycles of high pressure (compression) and low pressure (sparse), the rate of which depends on the frequency. During low-pressure cycling, high-intensity ultrasonic waves create small vacuum bubbles or voids in the liquid. When the bubbles reach a volume where they can no longer absorb energy, they collapse violently during high-pressure cycling, a phenomenon known as "cavitation." During the explosion, very high temperature (about 5,000K) and pressure (about 2,000 atm) will be reached locally. The collapse of the cavitation bubbles also results in a liquid jet with a velocity of up to 280 m/s, and the resulting shear force mechanically stirs the liquid to thoroughly mix the reactants.

The ultrasonic liquid processor consists of a probe and a power source. The processor is also haptic. When a liquid is treated with high-intensity ultrasound, the sound waves propagating into the liquid medium create alternating cycles of high pressure (compression) and low pressure (sparse), the rate of which depends on the frequency. During low-pressure cycling, high-intensity ultrasonic waves create small vacuum bubbles or voids in the liquid. When the bubbles reach a volume where they can no longer absorb energy, they collapse violently during high-pressure cycling, a phenomenon known as "cavitation." During the explosion, very high temperature (about 5,000K) and pressure (about 2,000 atm) will be reached locally. The collapse of the cavitation bubbles also results in a liquid jet with a velocity of up to 280 m/s, and the resulting shear force mechanically stirs the liquid to thoroughly mix the reactants.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

The ultrasonic technology of the ultrasonic homogenizer can cause an interaction between theSolid particles and the liquid,and high frequency vibration of ultrasound which suddenly increases the temperature of the liquid, emulsifies the two incompatible liquids, and accelerates the dissolution of the dissolved substance.

In addition, under the action of the ultrasonic homogenizer, even large and uneven materials can be mixed evenly with each other, thereby improving the stability of the product. Today, ultrasonic homogenizers have become one of indispensable equipment in the production of food, dairy, beverage, pharmaceutical and other processing companies.

Today, ultrasonic technology has been developed for civil use, such as ultrasonic dishwashers with functions such as cleaning, disinfecting and drying. Ultrasonic technology is expected to be more widely used in the food industry in the near future and has far-reaching effects on production efficiency, cleaning quality, uniformity of mixing and reducing resource waste of conventional food machines and equipment. It will bring great benefits to production and life.

1. No need to add any emulsification catalyst.

2. Core parts with Titanium materials

3. Ultrasonic horn(probe) with different size and type for selection

4. Matching with digital generator, auto-tuning, auto search frequency

5. With automatic alarm protection, easy to operate

6. Power adjustable from 1% to 99%

7. Amplitude stability, long working hours, radiation area is increased 2.5 times than

|  |

|

Food and Beverage Industry:

Emulsification of oil and water is crucial in the production of salad dressings, sauces, mayonnaise, and various food emulsions.Ultrasonic emulsification ensures uniform texture, stability, and enhanced mouthfeel in food products.

Pharmaceutical Industry:

Ultrasonic emulsification is used in pharmaceutical formulations to create stable emulsions for oral suspensions, creams, ointments, and injectables.It allows for precise control over particle size distribution and facilitates the delivery of active pharmaceutical ingredients.

|  |  |

Ultrasonic emulsification equipment works very well.

Since we added ultrasonic oil-water emulsification equipment and replaced our oil-water emulsification pump, our emulsification efficiency has improved a lot, and we have saved a lot of catalysts and costs.

You are very friendly and helpful. Thanks to the experts for the exchange.

Customer recognition and trust are our motivation.

Valvoline Technology takes "customer service first" as its corporate culture. The purpose is "quality first, service first". Today, Shengpai Technology has earned a very good reputation with its rich professional knowledge and good after-sales service.

1. What is ultrasonic emulsification?

Ultrasonic emulsification is a process that uses high-frequency sound waves to create fine and stable emulsions of oil and water. These sound waves break down the oil and water droplets into smaller sizes, resulting in a more uniform mixture.

2.How does ultrasonic emulsification equipment work?

Ultrasonic emulsification equipment typically consists of a generator that produces high-frequency sound waves and a probe or horn that delivers these waves into the liquid mixture. The sound waves cause cavitation, which is the formation and collapse of tiny bubbles, leading to the breakup of oil and water droplets.

3.Is ultrasonic emulsification suitable for all types of oils and liquids?

While ultrasonic emulsification can be used with many types of oils and liquids, the effectiveness may vary depending on factors such as viscosity, temperature, and chemical composition. It's essential to test the specific formulation to determine suitability.

4.How long do you make the order product?

Common products for 7days, big qty and none standard products for 20days.

5.Can ultrasonic emulsification equipment be scaled up for industrial production?

Yes, ultrasonic emulsification equipment is available in various sizes and configurations to accommodate different production scales. Industrial-scale systems can handle larger volumes and are designed for continuous operation.

6.Is ultrasonic emulsification environmentally friendly?

Ultrasonic emulsification can be considered environmentally friendly compared to some traditional emulsification methods, as it typically requires less energy and may reduce the need for certain chemicals. However, it's essential to consider factors such as energy consumption and waste management in the overall process.

7. Could you do OEM?

Yes, of course. We can produce according customers' requirement, just send us your requirements and design of drawing and sample.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

The ultrasonic liquid processor consists of a probe and a power source. The processor is also haptic. When a liquid is treated with high-intensity ultrasound, the sound waves propagating into the liquid medium create alternating cycles of high pressure (compression) and low pressure (sparse), the rate of which depends on the frequency. During low-pressure cycling, high-intensity ultrasonic waves create small vacuum bubbles or voids in the liquid. When the bubbles reach a volume where they can no longer absorb energy, they collapse violently during high-pressure cycling, a phenomenon known as "cavitation." During the explosion, very high temperature (about 5,000K) and pressure (about 2,000 atm) will be reached locally. The collapse of the cavitation bubbles also results in a liquid jet with a velocity of up to 280 m/s, and the resulting shear force mechanically stirs the liquid to thoroughly mix the reactants.

The ultrasonic liquid processor consists of a probe and a power source. The processor is also haptic. When a liquid is treated with high-intensity ultrasound, the sound waves propagating into the liquid medium create alternating cycles of high pressure (compression) and low pressure (sparse), the rate of which depends on the frequency. During low-pressure cycling, high-intensity ultrasonic waves create small vacuum bubbles or voids in the liquid. When the bubbles reach a volume where they can no longer absorb energy, they collapse violently during high-pressure cycling, a phenomenon known as "cavitation." During the explosion, very high temperature (about 5,000K) and pressure (about 2,000 atm) will be reached locally. The collapse of the cavitation bubbles also results in a liquid jet with a velocity of up to 280 m/s, and the resulting shear force mechanically stirs the liquid to thoroughly mix the reactants.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

The ultrasonic technology of the ultrasonic homogenizer can cause an interaction between theSolid particles and the liquid,and high frequency vibration of ultrasound which suddenly increases the temperature of the liquid, emulsifies the two incompatible liquids, and accelerates the dissolution of the dissolved substance.

In addition, under the action of the ultrasonic homogenizer, even large and uneven materials can be mixed evenly with each other, thereby improving the stability of the product. Today, ultrasonic homogenizers have become one of indispensable equipment in the production of food, dairy, beverage, pharmaceutical and other processing companies.

Today, ultrasonic technology has been developed for civil use, such as ultrasonic dishwashers with functions such as cleaning, disinfecting and drying. Ultrasonic technology is expected to be more widely used in the food industry in the near future and has far-reaching effects on production efficiency, cleaning quality, uniformity of mixing and reducing resource waste of conventional food machines and equipment. It will bring great benefits to production and life.

1. No need to add any emulsification catalyst.

2. Core parts with Titanium materials

3. Ultrasonic horn(probe) with different size and type for selection

4. Matching with digital generator, auto-tuning, auto search frequency

5. With automatic alarm protection, easy to operate

6. Power adjustable from 1% to 99%

7. Amplitude stability, long working hours, radiation area is increased 2.5 times than

|  |

|

Food and Beverage Industry:

Emulsification of oil and water is crucial in the production of salad dressings, sauces, mayonnaise, and various food emulsions.Ultrasonic emulsification ensures uniform texture, stability, and enhanced mouthfeel in food products.

Pharmaceutical Industry:

Ultrasonic emulsification is used in pharmaceutical formulations to create stable emulsions for oral suspensions, creams, ointments, and injectables.It allows for precise control over particle size distribution and facilitates the delivery of active pharmaceutical ingredients.

|  |  |

Ultrasonic emulsification equipment works very well.

Since we added ultrasonic oil-water emulsification equipment and replaced our oil-water emulsification pump, our emulsification efficiency has improved a lot, and we have saved a lot of catalysts and costs.

You are very friendly and helpful. Thanks to the experts for the exchange.

Customer recognition and trust are our motivation.

Valvoline Technology takes "customer service first" as its corporate culture. The purpose is "quality first, service first". Today, Shengpai Technology has earned a very good reputation with its rich professional knowledge and good after-sales service.

1. What is ultrasonic emulsification?

Ultrasonic emulsification is a process that uses high-frequency sound waves to create fine and stable emulsions of oil and water. These sound waves break down the oil and water droplets into smaller sizes, resulting in a more uniform mixture.

2.How does ultrasonic emulsification equipment work?

Ultrasonic emulsification equipment typically consists of a generator that produces high-frequency sound waves and a probe or horn that delivers these waves into the liquid mixture. The sound waves cause cavitation, which is the formation and collapse of tiny bubbles, leading to the breakup of oil and water droplets.

3.Is ultrasonic emulsification suitable for all types of oils and liquids?

While ultrasonic emulsification can be used with many types of oils and liquids, the effectiveness may vary depending on factors such as viscosity, temperature, and chemical composition. It's essential to test the specific formulation to determine suitability.

4.How long do you make the order product?

Common products for 7days, big qty and none standard products for 20days.

5.Can ultrasonic emulsification equipment be scaled up for industrial production?

Yes, ultrasonic emulsification equipment is available in various sizes and configurations to accommodate different production scales. Industrial-scale systems can handle larger volumes and are designed for continuous operation.

6.Is ultrasonic emulsification environmentally friendly?

Ultrasonic emulsification can be considered environmentally friendly compared to some traditional emulsification methods, as it typically requires less energy and may reduce the need for certain chemicals. However, it's essential to consider factors such as energy consumption and waste management in the overall process.

7. Could you do OEM?

Yes, of course. We can produce according customers' requirement, just send us your requirements and design of drawing and sample.

8. Payment:100%T/T in advance for small order. 70%T/T in advance as deposit, 30%T/T paid before shipment

9. Delivery?

1-2 units we could send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight LCL or by air.

10. Warranty:

One years Warranty with none human damage. After warranty time, factory will repair fix it or send the new parts on cost price.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.