| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

Emulsions consist of two or more liquids that don't mix well. Using highly intense ultrasound, we can generate the energy required to break one liquid phase (the dispersed phase) into tiny droplets dispersed within another liquid phase (the continuous phase). Within the zone where dispersion occurs, collapsing cavitation bubbles create powerful shock waves in the liquid around them, leading to the formation of high-velocity liquid jets. With the right energy density, ultrasound can effectively produce droplets with a mean size below 1 micron, creating what's known as a micro-emulsion.

This equipment from SP TECH is suitable for laboratory, enterprise experiments, or pilot trials. The reactor comes with a built-in jacket and can be cooled by circulating cooling water to precisely control the slurry 2.temperature within the range of 10-40°C. The ultrasonic output power is adjustable, and the ultrasonic vibrator, designed for optimal performance, can effectively peel graphene layers longitudinally, resulting in excellent peeling effects.

Our ultrasonic emulsifying equipment is dedicated to the research and development of high-power ultrasound applications. We boast cutting-edge core technology, the most stable and mature manufacturing processes, and extensive experience. We offer comprehensive support, including direct demonstrations of ultrasonic applications, structural design, system configuration, and production of related parts.

1.Efficient Emulsification: Ultrasonic emulsification rapidly breaks down immiscible liquids into fine droplets, leading to a homogeneous mixture.

2.Enhanced Stability: The resulting emulsions exhibit improved stability due to the uniform distribution of droplets achieved through ultrasonic processing.

3.Precise Control: Ultrasonic emulsification allows for precise control over droplet size, facilitating customization according to specific application requirements.

4.Reduced Processing Time: Compared to traditional methods, ultrasonic emulsification significantly reduces processing time, leading to increased productivity.

5.Minimal Additives: Ultrasonic emulsification often requires fewer additives or stabilizers, reducing costs and simplifying the formulation process.

6.Scalability: The technology is scalable, making it suitable for laboratory-scale experiments as well as large-scale industrial production.

7.Energy Efficiency: Ultrasonic emulsification is energy-efficient, contributing to lower operational costs and environmental sustainability.

8.Versatility: It can be applied to a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, offering versatile emulsification solutions.

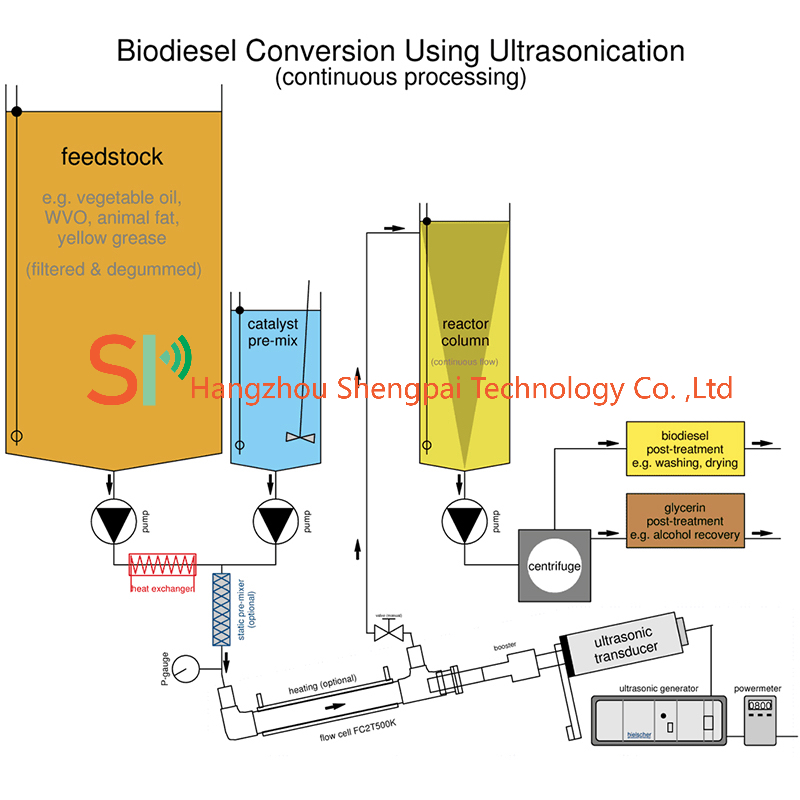

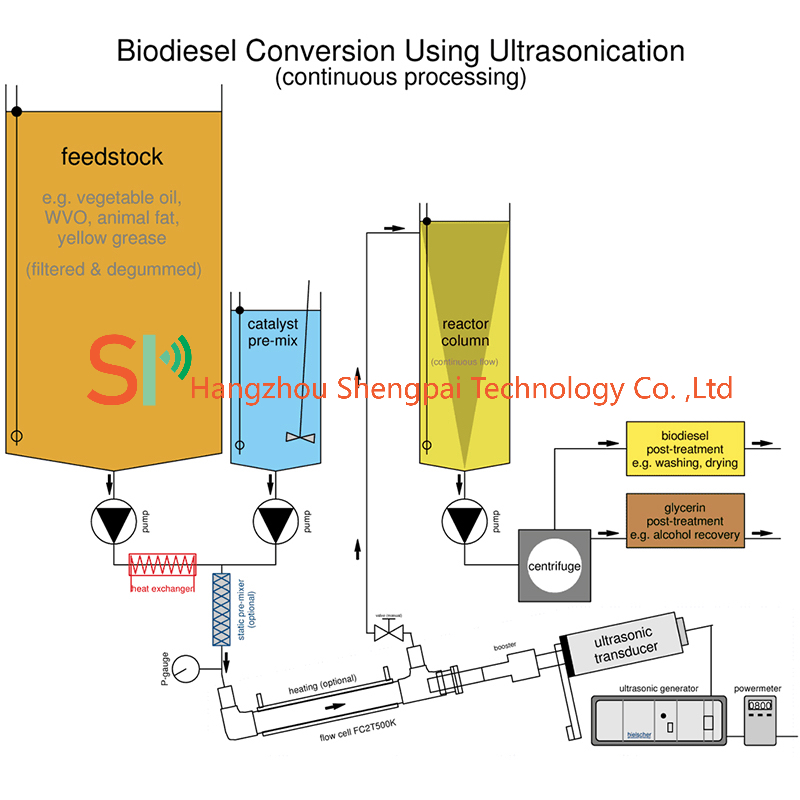

Ultrasonic treatment of chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalytic efficiency of catalysts, biodegradation treatment, ultrasonic anti-scaling, biological cell comminution, dispersion and coagulation A local small environment that is very beneficial to the reaction process can greatly increase the reaction rate and reduce the reaction conditions.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Customers' evalution as follow:

The ultrasonic sonicator works very well.

The Ultrasonic Liquid Processor For Oil Emulsification efficient emulsification capabilities streamline our processes, reducing time and effort. The device's precision ensures consistent results, crucial for our research. Its user-friendly interface simplifies operation, making it accessible even for less experienced technicians. Overall, it's a valuable addition, enhancing our productivity and experimental outcomes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Emulsions consist of two or more liquids that don't mix well. Using highly intense ultrasound, we can generate the energy required to break one liquid phase (the dispersed phase) into tiny droplets dispersed within another liquid phase (the continuous phase). Within the zone where dispersion occurs, collapsing cavitation bubbles create powerful shock waves in the liquid around them, leading to the formation of high-velocity liquid jets. With the right energy density, ultrasound can effectively produce droplets with a mean size below 1 micron, creating what's known as a micro-emulsion.

This equipment from SP TECH is suitable for laboratory, enterprise experiments, or pilot trials. The reactor comes with a built-in jacket and can be cooled by circulating cooling water to precisely control the slurry 2.temperature within the range of 10-40°C. The ultrasonic output power is adjustable, and the ultrasonic vibrator, designed for optimal performance, can effectively peel graphene layers longitudinally, resulting in excellent peeling effects.

Our ultrasonic emulsifying equipment is dedicated to the research and development of high-power ultrasound applications. We boast cutting-edge core technology, the most stable and mature manufacturing processes, and extensive experience. We offer comprehensive support, including direct demonstrations of ultrasonic applications, structural design, system configuration, and production of related parts.

1.Efficient Emulsification: Ultrasonic emulsification rapidly breaks down immiscible liquids into fine droplets, leading to a homogeneous mixture.

2.Enhanced Stability: The resulting emulsions exhibit improved stability due to the uniform distribution of droplets achieved through ultrasonic processing.

3.Precise Control: Ultrasonic emulsification allows for precise control over droplet size, facilitating customization according to specific application requirements.

4.Reduced Processing Time: Compared to traditional methods, ultrasonic emulsification significantly reduces processing time, leading to increased productivity.

5.Minimal Additives: Ultrasonic emulsification often requires fewer additives or stabilizers, reducing costs and simplifying the formulation process.

6.Scalability: The technology is scalable, making it suitable for laboratory-scale experiments as well as large-scale industrial production.

7.Energy Efficiency: Ultrasonic emulsification is energy-efficient, contributing to lower operational costs and environmental sustainability.

8.Versatility: It can be applied to a wide range of industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals, offering versatile emulsification solutions.

Ultrasonic treatment of chemical extraction, biodiesel production, organic synthesis, treatment of microorganisms, degradation of toxic organic pollutants, chemical reaction rate and yield, catalytic efficiency of catalysts, biodegradation treatment, ultrasonic anti-scaling, biological cell comminution, dispersion and coagulation A local small environment that is very beneficial to the reaction process can greatly increase the reaction rate and reduce the reaction conditions.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Customers' evalution as follow:

The ultrasonic sonicator works very well.

The Ultrasonic Liquid Processor For Oil Emulsification efficient emulsification capabilities streamline our processes, reducing time and effort. The device's precision ensures consistent results, crucial for our research. Its user-friendly interface simplifies operation, making it accessible even for less experienced technicians. Overall, it's a valuable addition, enhancing our productivity and experimental outcomes.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.