| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

Ultrasonic homogenizer is a well-established method for emulsifying. Ultrasonic processors are used in the generation of nano-size material slurries, dispersions and emulsions because of the potential in the deagglomeration and the reduction of primaries. These are the mechanical effects of ultrsonic cavitation. Ultrasonic can also be used to influence chemical reactions by the cavitation energy.

As the market for nano-size materials grows, the demand for ultrasonic processes at production level increases.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic homogenizing for Nano materials attracted the attention of scientists, researchers and engineers of almost any branches as nano-sized particles show unique characteristics. Their physical properties such as optical and magnetic properties, specific heats, melting points, and surface reactivity offer high potentials for material with extraordinary strengths. But the smaller particles, the more difficult becomes treatment. Ultrasonic homogenizer is often the best method to effect nano particles effectively. Mostly, high power ultrasonic homogenizer are the only efficient way to achieve the desired milling and dispersing results of nano particles such as nanotubes, graphene, metal oxides etc.

1. Wide range of application, not only can be used for plant and cell wall breaking extraction, but also for dispersion stripping of graphene, carbon tube, etc., can also be used for various oil-water emulsification for cosmetics and pharmaceutical industry, food industry.

2. The dispersion quality of ultrasonic homogenizer is good, the dispersion particles are small, the dispersion cost is low, and the energy consumption is small.

3. The extraction rate of ultrasonic homogenizer is significantly increased by 50%-500% compared with the traditional process, and the extraction time is short, the applicability is wide, and the extract purity is high.

4. The homogenizing emulsification of ultrasonic homogenizers can produce droplets of smaller size, and the number of surfactants required to provide a stable emulsion is usually lower than other technologies.

1. High quality titanium alloy horn with long uselife

2. Ultrasonic horn with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 10% to 99%

6. Amplitude stability, long working hours, radiation area is increased 2.5 times than traditional tools

7. Provide consulting services and custom reactor designs

8. Custom sizes available for laboratory and high volume industrial applications.

Ultrasonic sonciators are powerful, but they also generate a lot of heat and noise as a result of their use of ultrasonic energy.

Therefore, it is highly recommended that you use ear protectors and/or keep them in an insulated housing to reduce noise levels during the homogenization process.

Reaction kettle, cooling device and circulation device can be designed according to your application requirements.

To maximize the life of the speaker, clean and dry the speaker after each use.

Failure to properly maintain the horn can lead to pitting (localized corrosion that creates holes in the titanium), which can reduce the horn's effectiveness.

Ultrasonic homogenizers must be used with liquid samples.

They are not suitable for dry homogenization applications.

Immerse the horn into the sample before turning on the instrument and ensure that the horn does not touch the sides of the container during operation.

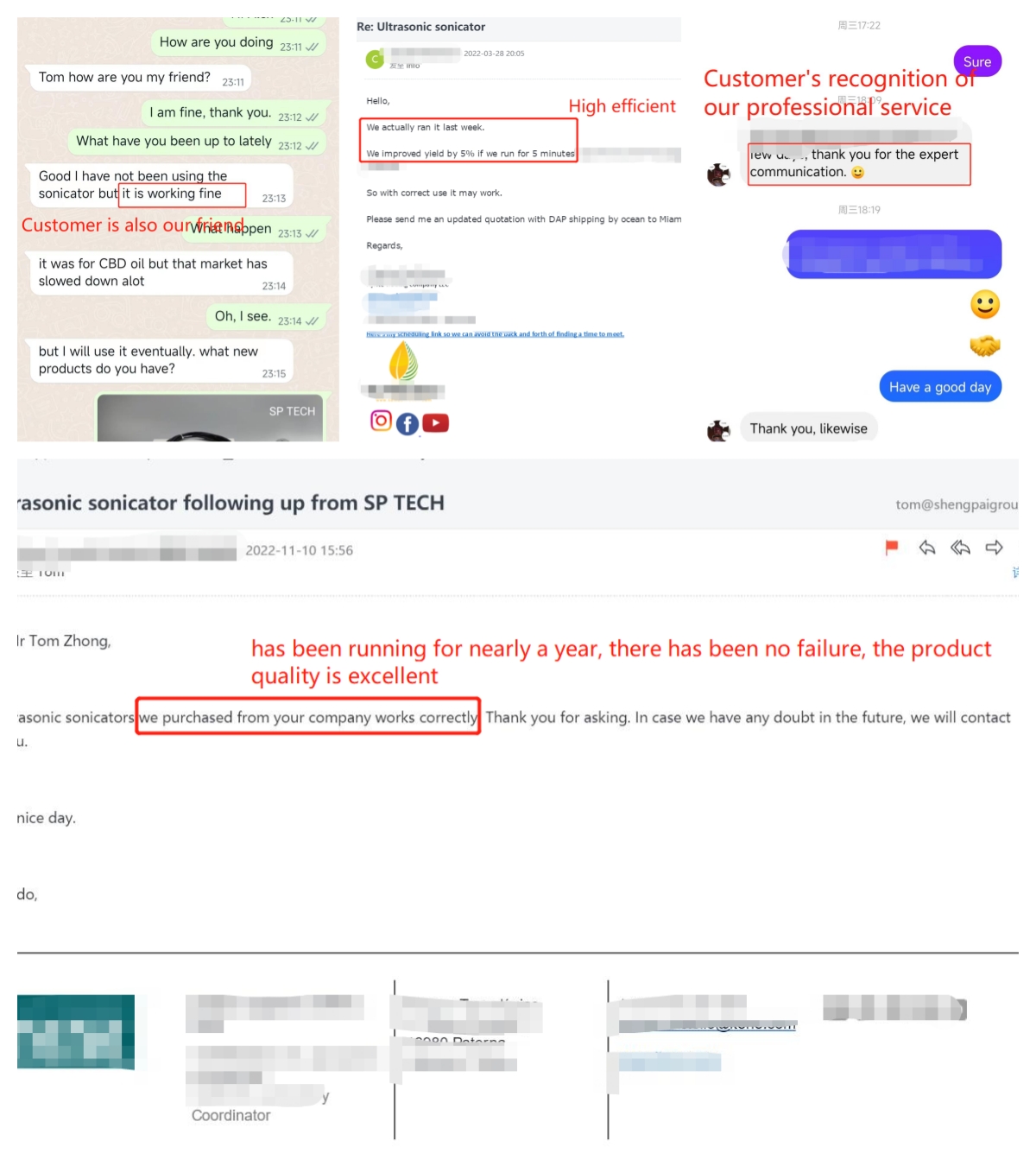

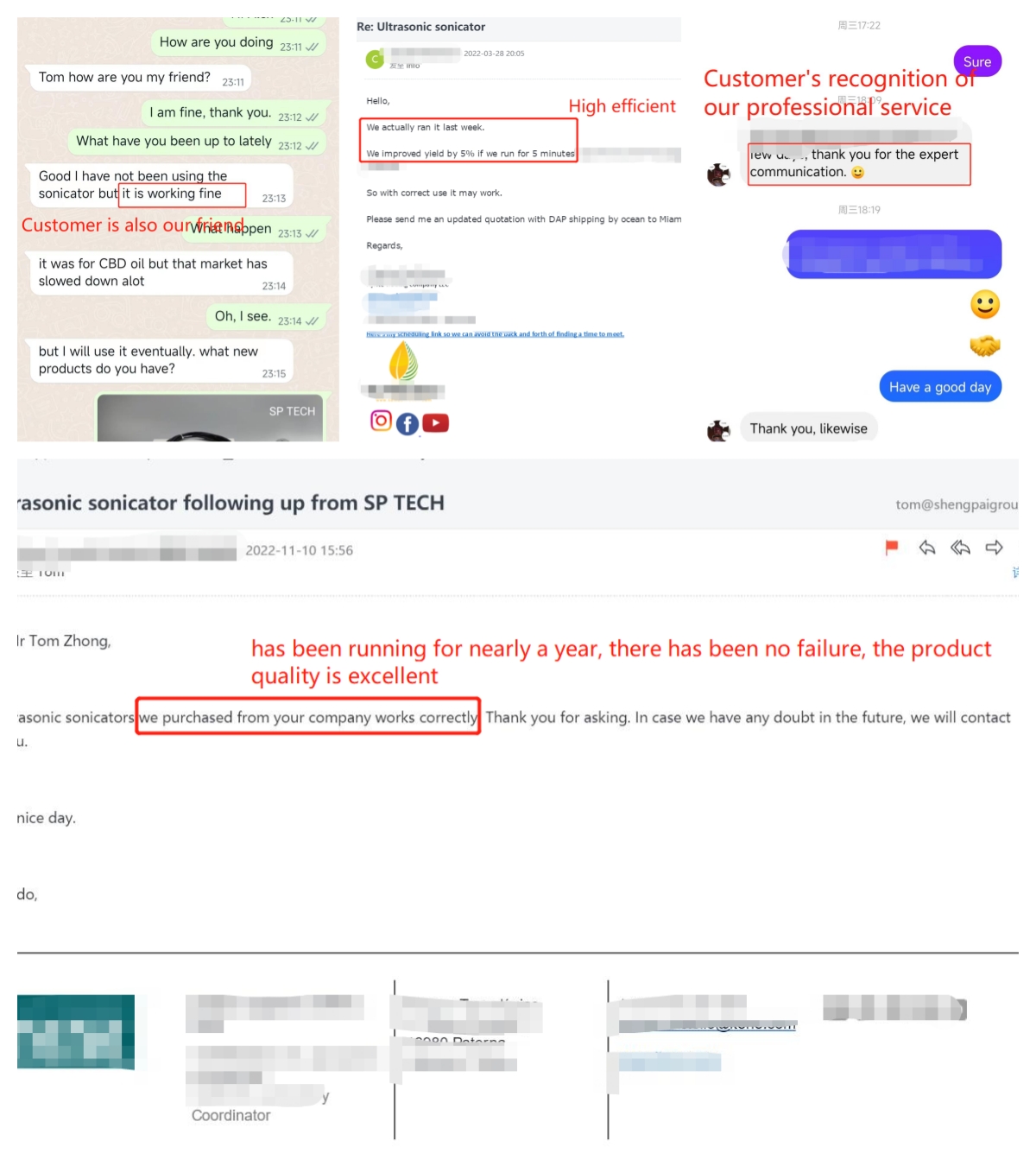

Customers' evalution as follow:

The ultrasonic sonicator works very well. It improved yield than before.

I am very glad that under your professional introduction, the ultrasonic homogenizer is used for emulsification, which is more efficient and has better emulsification quality than the conventional method.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic homogenizer is a well-established method for emulsifying. Ultrasonic processors are used in the generation of nano-size material slurries, dispersions and emulsions because of the potential in the deagglomeration and the reduction of primaries. These are the mechanical effects of ultrsonic cavitation. Ultrasonic can also be used to influence chemical reactions by the cavitation energy.

As the market for nano-size materials grows, the demand for ultrasonic processes at production level increases.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic homogenizing for Nano materials attracted the attention of scientists, researchers and engineers of almost any branches as nano-sized particles show unique characteristics. Their physical properties such as optical and magnetic properties, specific heats, melting points, and surface reactivity offer high potentials for material with extraordinary strengths. But the smaller particles, the more difficult becomes treatment. Ultrasonic homogenizer is often the best method to effect nano particles effectively. Mostly, high power ultrasonic homogenizer are the only efficient way to achieve the desired milling and dispersing results of nano particles such as nanotubes, graphene, metal oxides etc.

1. Wide range of application, not only can be used for plant and cell wall breaking extraction, but also for dispersion stripping of graphene, carbon tube, etc., can also be used for various oil-water emulsification for cosmetics and pharmaceutical industry, food industry.

2. The dispersion quality of ultrasonic homogenizer is good, the dispersion particles are small, the dispersion cost is low, and the energy consumption is small.

3. The extraction rate of ultrasonic homogenizer is significantly increased by 50%-500% compared with the traditional process, and the extraction time is short, the applicability is wide, and the extract purity is high.

4. The homogenizing emulsification of ultrasonic homogenizers can produce droplets of smaller size, and the number of surfactants required to provide a stable emulsion is usually lower than other technologies.

1. High quality titanium alloy horn with long uselife

2. Ultrasonic horn with different size and type for selection

3. Matching with digital generator, auto-tuning, auto search frequency

4. With automatic alarm protection, easy to operate

5. Power adjustable from 10% to 99%

6. Amplitude stability, long working hours, radiation area is increased 2.5 times than traditional tools

7. Provide consulting services and custom reactor designs

8. Custom sizes available for laboratory and high volume industrial applications.

Ultrasonic sonciators are powerful, but they also generate a lot of heat and noise as a result of their use of ultrasonic energy.

Therefore, it is highly recommended that you use ear protectors and/or keep them in an insulated housing to reduce noise levels during the homogenization process.

Reaction kettle, cooling device and circulation device can be designed according to your application requirements.

To maximize the life of the speaker, clean and dry the speaker after each use.

Failure to properly maintain the horn can lead to pitting (localized corrosion that creates holes in the titanium), which can reduce the horn's effectiveness.

Ultrasonic homogenizers must be used with liquid samples.

They are not suitable for dry homogenization applications.

Immerse the horn into the sample before turning on the instrument and ensure that the horn does not touch the sides of the container during operation.

Customers' evalution as follow:

The ultrasonic sonicator works very well. It improved yield than before.

I am very glad that under your professional introduction, the ultrasonic homogenizer is used for emulsification, which is more efficient and has better emulsification quality than the conventional method.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.