| Availability: | |

|---|---|

| Quantity: | |

SP-M20S

SP

8543709990

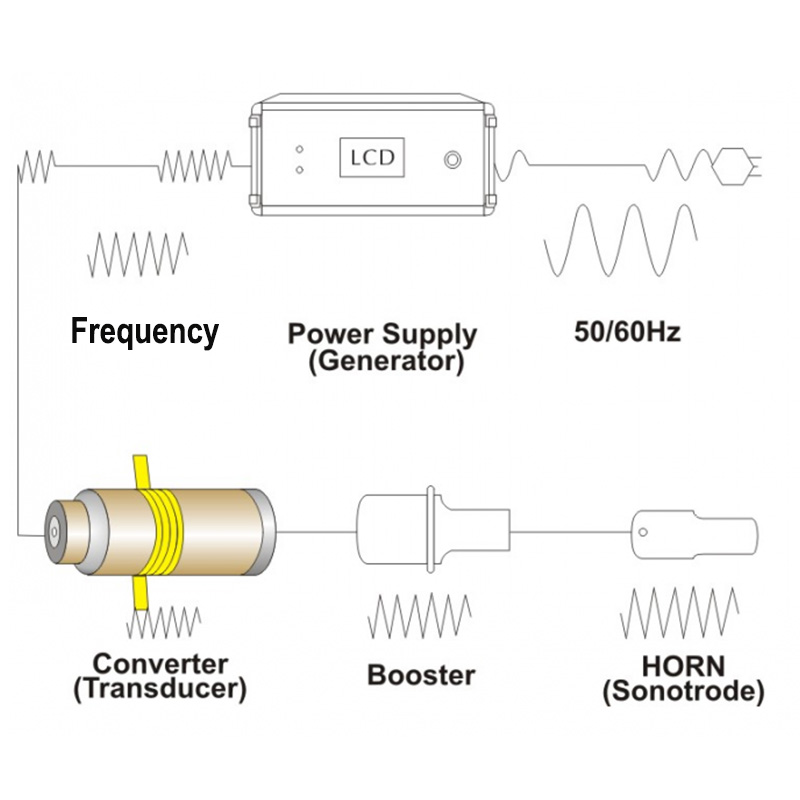

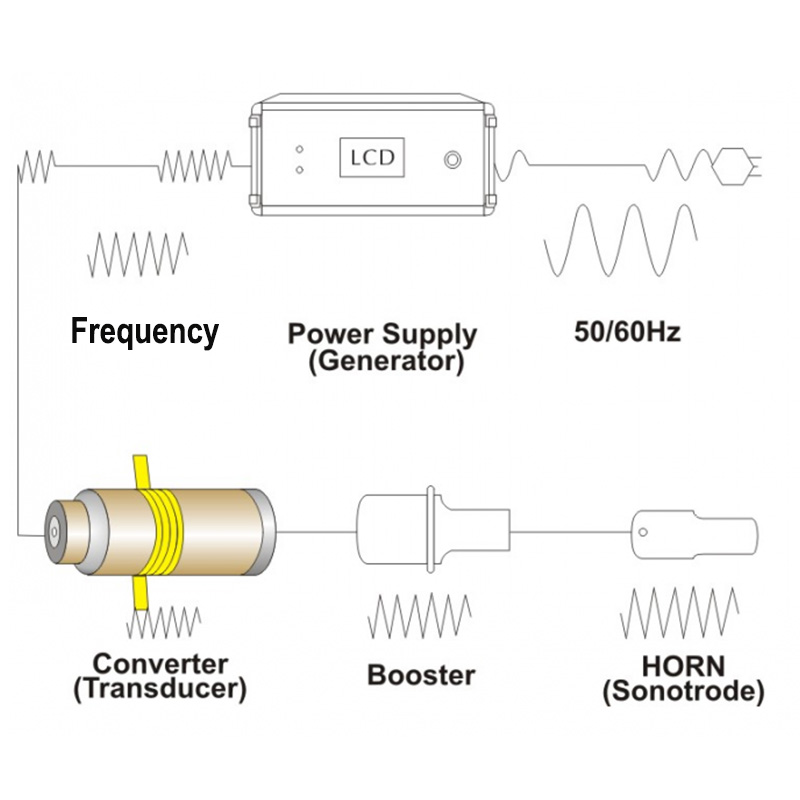

Ultrasonic welding is a widely used method for joining thermoplastic materials. It involves the application of high-frequency mechanical vibrations to two plastic parts held together under pressure to generate localized heat, causing the plastic to melt and fuse together. Ultrasonic welding is a popular choice for joining plastic parts as it is fast, cost- effective, and produces strong, hermetic welds with minimal thermal distortion.

Ultrasonic welding is a widely used method for joining thermoplastic materials. It involves the application of high-frequency mechanical vibrations to two plastic parts held together under pressure to generate localized heat, causing the plastic to melt and fuse together. Ultrasonic welding is a popular choice for joining plastic parts as it is fast, cost- effective, and produces strong, hermetic welds with minimal thermal distortion.

We can provide booster and sonotrode together as your needs.

It is drove by SP TECH digital ultrasonic generator which is adopting advanced IGBT Full Bridge Phase Shift technology and features in automatic frequency tracking and constant amplitude output etc which can achieve accurate resonant frequency and energy output. It can tune itself to fit to transducer and sonotrode during working.

| Name | Ultrasonic Transducer | Ultrasonic Generator |

| Model | SP-5020-4Z | SP-HJ3000 |

| Ultrasonic Frequency | 20±0.5Khz | 20±0.5Khz |

| Ultrasonic Power | 2000 Watt | 2000 Watt |

| Work Method | - | intermittent wave/continuous wave |

| Capacitance | 11000 ±10%pF | - |

| Resistance | ≤10Ω | - |

| Max.Allowable | 75℃ | 0~40℃ |

| Storage Temperature | -5℃~+40℃ | -5℃~+40℃ |

| Working Area | 110X20mm | - |

| Size | H253mm X θ 63mm | 350(L)*310(W)*150(H)mm |

| Weight | 8Kg | 9Kg |

| Power Supply | - | 220V, 50/60Hz, 1 Phase |

Ultrasonic welding has several advantages over other welding techniques. It is fast and produces strong, hermetic welds with minimal thermal distortion. It is also a cost-effective method, as it requires no additional materials such as adhesives or solvents. Additionally, the process can be easily automated for high-volume production.

Ultrasonic welding has several advantages over other welding techniques. It is fast and produces strong, hermetic welds with minimal thermal distortion. It is also a cost-effective method, as it requires no additional materials such as adhesives or solvents. Additionally, the process can be easily automated for high-volume production.

|  |  |

Customers' evalution as follow:

The ultrasonic welding system works very well.

The performance of welding equipment has been greatly improved.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic welding is a widely used method for joining thermoplastic materials. It involves the application of high-frequency mechanical vibrations to two plastic parts held together under pressure to generate localized heat, causing the plastic to melt and fuse together. Ultrasonic welding is a popular choice for joining plastic parts as it is fast, cost- effective, and produces strong, hermetic welds with minimal thermal distortion.

Ultrasonic welding is a widely used method for joining thermoplastic materials. It involves the application of high-frequency mechanical vibrations to two plastic parts held together under pressure to generate localized heat, causing the plastic to melt and fuse together. Ultrasonic welding is a popular choice for joining plastic parts as it is fast, cost- effective, and produces strong, hermetic welds with minimal thermal distortion.

We can provide booster and sonotrode together as your needs.

It is drove by SP TECH digital ultrasonic generator which is adopting advanced IGBT Full Bridge Phase Shift technology and features in automatic frequency tracking and constant amplitude output etc which can achieve accurate resonant frequency and energy output. It can tune itself to fit to transducer and sonotrode during working.

| Name | Ultrasonic Transducer | Ultrasonic Generator |

| Model | SP-5020-4Z | SP-HJ3000 |

| Ultrasonic Frequency | 20±0.5Khz | 20±0.5Khz |

| Ultrasonic Power | 2000 Watt | 2000 Watt |

| Work Method | - | intermittent wave/continuous wave |

| Capacitance | 11000 ±10%pF | - |

| Resistance | ≤10Ω | - |

| Max.Allowable | 75℃ | 0~40℃ |

| Storage Temperature | -5℃~+40℃ | -5℃~+40℃ |

| Working Area | 110X20mm | - |

| Size | H253mm X θ 63mm | 350(L)*310(W)*150(H)mm |

| Weight | 8Kg | 9Kg |

| Power Supply | - | 220V, 50/60Hz, 1 Phase |

Ultrasonic welding has several advantages over other welding techniques. It is fast and produces strong, hermetic welds with minimal thermal distortion. It is also a cost-effective method, as it requires no additional materials such as adhesives or solvents. Additionally, the process can be easily automated for high-volume production.

Ultrasonic welding has several advantages over other welding techniques. It is fast and produces strong, hermetic welds with minimal thermal distortion. It is also a cost-effective method, as it requires no additional materials such as adhesives or solvents. Additionally, the process can be easily automated for high-volume production.

|  |  |

Customers' evalution as follow:

The ultrasonic welding system works very well.

The performance of welding equipment has been greatly improved.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.