| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

ultrasonic extractor is based on the ultrasonic transducer to generate fast mechanical vibration waves. Using ultrasonic energy, the uniformity of ultrasonic action is improved, and the sound intensity is increased, which makes the granular surface layer too thin, the surface falls off, the particles are broken, and the outer wall of the cell is crushed by ultrasonic waves. , so that the substance in the cell wall of the mechanism is dispersed into the solution, the process of dissolving the relevant components in the substance in the organic solvent is accelerated, and the interaction force between the overall target purified substance and the sample substrate is reduced, so as to achieve solid-liquid purification and extraction. out to improve the extraction rate of related components.

ultrasonic extractor is based on the ultrasonic transducer to generate fast mechanical vibration waves. Using ultrasonic energy, the uniformity of ultrasonic action is improved, and the sound intensity is increased, which makes the granular surface layer too thin, the surface falls off, the particles are broken, and the outer wall of the cell is crushed by ultrasonic waves. , so that the substance in the cell wall of the mechanism is dispersed into the solution, the process of dissolving the relevant components in the substance in the organic solvent is accelerated, and the interaction force between the overall target purified substance and the sample substrate is reduced, so as to achieve solid-liquid purification and extraction. out to improve the extraction rate of related components.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

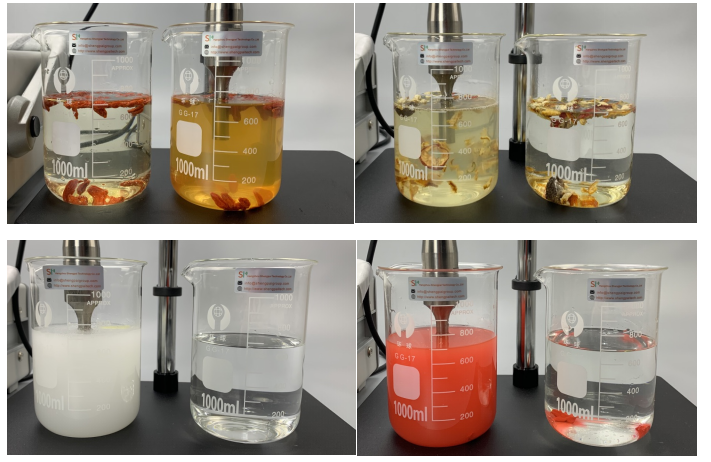

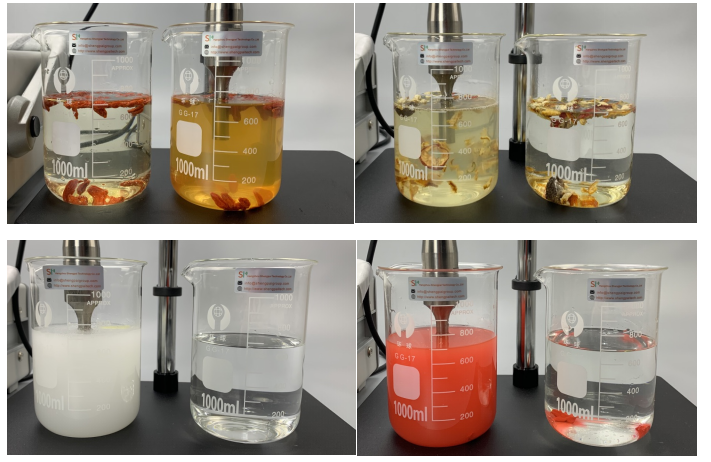

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

1.Efficient Homogenization: Ultrasonic homogenizers use high-frequency sound waves to disrupt particles and create a uniform mixture. This method is highly efficient and can homogenize samples in a relatively short time compared to traditional methods.

2.Reduced Sample Contamination: Unlike mechanical homogenizers, ultrasonic homogenizers don't require any contact between the equipment and the sample. This reduces the risk of contamination, making them ideal for sensitive samples such as biological tissues or pharmaceutical compounds.

3.Scalability: Ultrasonic homogenizers are available in various sizes, from benchtop models for small-scale research to industrial-scale units for large-scale production. This scalability allows users to scale up their processes as needed without compromising efficiency or quality.

4.Versatility: Ultrasonic homogenizers can be used for a wide range of applications, including emulsification, dispersion, cell disruption, and nanoparticle synthesis. They are adaptable to different sample types and can accommodate various vessel sizes and shapes.

5.Energy Efficiency: Compared to other homogenization methods, such as mechanical shearing or grinding, ultrasonic homogenization typically requires less energy input. This can result in cost savings and reduced environmental impact, especially in large-scale industrial applications.

Let's delve into the firsthand experience of a user who integrated our Ultrasonic Tech into their homogenization process:

Li, a production manager in the pharmaceutical industry, was facing challenges with traditional homogenization methods. The need for precise particle size distribution and the demand for faster production led him to explore ultrasonic technology. After implementing our Ultrasonic Tech, Li experienced a remarkable improvement in efficiency and product quality. The results were not just satisfying but exceeded his expectations, making the switch a game-changer for his production line.

ultrasonic extractor is based on the ultrasonic transducer to generate fast mechanical vibration waves. Using ultrasonic energy, the uniformity of ultrasonic action is improved, and the sound intensity is increased, which makes the granular surface layer too thin, the surface falls off, the particles are broken, and the outer wall of the cell is crushed by ultrasonic waves. , so that the substance in the cell wall of the mechanism is dispersed into the solution, the process of dissolving the relevant components in the substance in the organic solvent is accelerated, and the interaction force between the overall target purified substance and the sample substrate is reduced, so as to achieve solid-liquid purification and extraction. out to improve the extraction rate of related components.

ultrasonic extractor is based on the ultrasonic transducer to generate fast mechanical vibration waves. Using ultrasonic energy, the uniformity of ultrasonic action is improved, and the sound intensity is increased, which makes the granular surface layer too thin, the surface falls off, the particles are broken, and the outer wall of the cell is crushed by ultrasonic waves. , so that the substance in the cell wall of the mechanism is dispersed into the solution, the process of dissolving the relevant components in the substance in the organic solvent is accelerated, and the interaction force between the overall target purified substance and the sample substrate is reduced, so as to achieve solid-liquid purification and extraction. out to improve the extraction rate of related components.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic extraction is used in the food, nutritional supplement and pharmaceutical industry to release bioactive compounds such as vitamins, polyphenols, polysaccharides, cannabinoids and other phytochemicals from botanicals. The ultrasound-assisted extraction is based on the working principle of acoustic or ultrasonic cavitation.

1.Efficient Homogenization: Ultrasonic homogenizers use high-frequency sound waves to disrupt particles and create a uniform mixture. This method is highly efficient and can homogenize samples in a relatively short time compared to traditional methods.

2.Reduced Sample Contamination: Unlike mechanical homogenizers, ultrasonic homogenizers don't require any contact between the equipment and the sample. This reduces the risk of contamination, making them ideal for sensitive samples such as biological tissues or pharmaceutical compounds.

3.Scalability: Ultrasonic homogenizers are available in various sizes, from benchtop models for small-scale research to industrial-scale units for large-scale production. This scalability allows users to scale up their processes as needed without compromising efficiency or quality.

4.Versatility: Ultrasonic homogenizers can be used for a wide range of applications, including emulsification, dispersion, cell disruption, and nanoparticle synthesis. They are adaptable to different sample types and can accommodate various vessel sizes and shapes.

5.Energy Efficiency: Compared to other homogenization methods, such as mechanical shearing or grinding, ultrasonic homogenization typically requires less energy input. This can result in cost savings and reduced environmental impact, especially in large-scale industrial applications.

Let's delve into the firsthand experience of a user who integrated our Ultrasonic Tech into their homogenization process:

Li, a production manager in the pharmaceutical industry, was facing challenges with traditional homogenization methods. The need for precise particle size distribution and the demand for faster production led him to explore ultrasonic technology. After implementing our Ultrasonic Tech, Li experienced a remarkable improvement in efficiency and product quality. The results were not just satisfying but exceeded his expectations, making the switch a game-changer for his production line.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.