| Availability: | |

|---|---|

| Quantity: | |

SPS20-1600S

SP

8543709990

Ultrasonic extraction is achieved when high-power, low-frequency ultrasound waves are coupled into a slurry consisting of botanical material in a solvent. High-power ultrasonic waves are coupled via a probe-type ultrasonic processor into the slurry. highly energetic ultrasound waves travel through the liquid creating alternating high-pressure / low-pressure cycles, which results in the phenomenon of acoustic cavitation. Acoustic or ultrasonic cavitation leads locally to extreme temperatures, pressures, heating/cooling rates, pressure differentials and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues etc.), micro-jets and interparticlular collision generate effects such as surface peeling, erosion, particle breakdown, sonoporation (the perforation of cell walls and cell membranes) and cell disruption. Additionally, the implosion of cavitation bubbles in liquid media create macro-turbulences and micro-mixing. Ultrasonic irradiation represents an efficient way to enhance mass transfer processes, since sonication results in cavitation and its related mechanisms such as micros-movement by liquid jets, compression and decompression in the material with the subsequent disruption of cell walls, as well as high heating and cooling rates. Probe-type ultrasonicators can generate very high amplitudes, which is necessary to generate impactful cavitation. SP TECH Ultrasonic manufactures high-performance ultrasonic extractors, which can easily create amplitudes of 100µm in continuous operation.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Pharmaceutical Industry: Enables the extraction of active compounds from medicinal herbs, facilitating the development of natural-based medications and herbal supplements.

2. Cosmetics Industry: Supports the extraction of natural ingredients for the formulation of skincare products, enhancing their efficacy and promoting the use of botanical extracts in cosmetics.

3. Food and Beverage Industry: Facilitates the extraction of flavors, colors, and bioactive compounds from herbs, enhancing the taste, appearance, and nutritional value of food and beverages.

4. Nutraceutical Industry: Assists in the extraction of bioactive compounds for the formulation of dietary supplements, promoting natural health and wellness solutions.

5. Agriculture and Horticulture: Supports research and development in plant breeding, genetic studies, and crop improvement by enabling the extraction of valuable compounds from herb tissues.

6. Essential Oil Production: Supports the extraction of essential oils from aromatic herbs, ensuring high-quality oils with preserved fragrance and therapeutic properties.

1. Ultrasonic extraction can achieve higher extraction yields in a shorter time compared to traditional extraction methods such as maceration and Soxhlet extraction.

2. Ultrasonic extraction can extract compounds within minutes to a few hours, which is much faster than traditional extraction methods that may take several days or even weeks.

3. Ultrasonic extraction can be used to extract specific compounds by adjusting the frequency, power, and duration of the sound waves. This makes it possible to selectively extract the target compounds without extracting unwanted compounds.

4. Ultrasonic extraction uses only water or other solvents, eliminating the need for toxic solvents that are harmful to the environment and human health.

5. Ultrasonic extraction is easy to scale up from laboratory to industrial production. The same equipment can be used for small-scale and large-scale production, which makes it a cost-effective extraction technique.

6. Ultrasonic extraction can extract high-quality compounds with a higher purity and better bioactivity compared to traditional extraction methods.

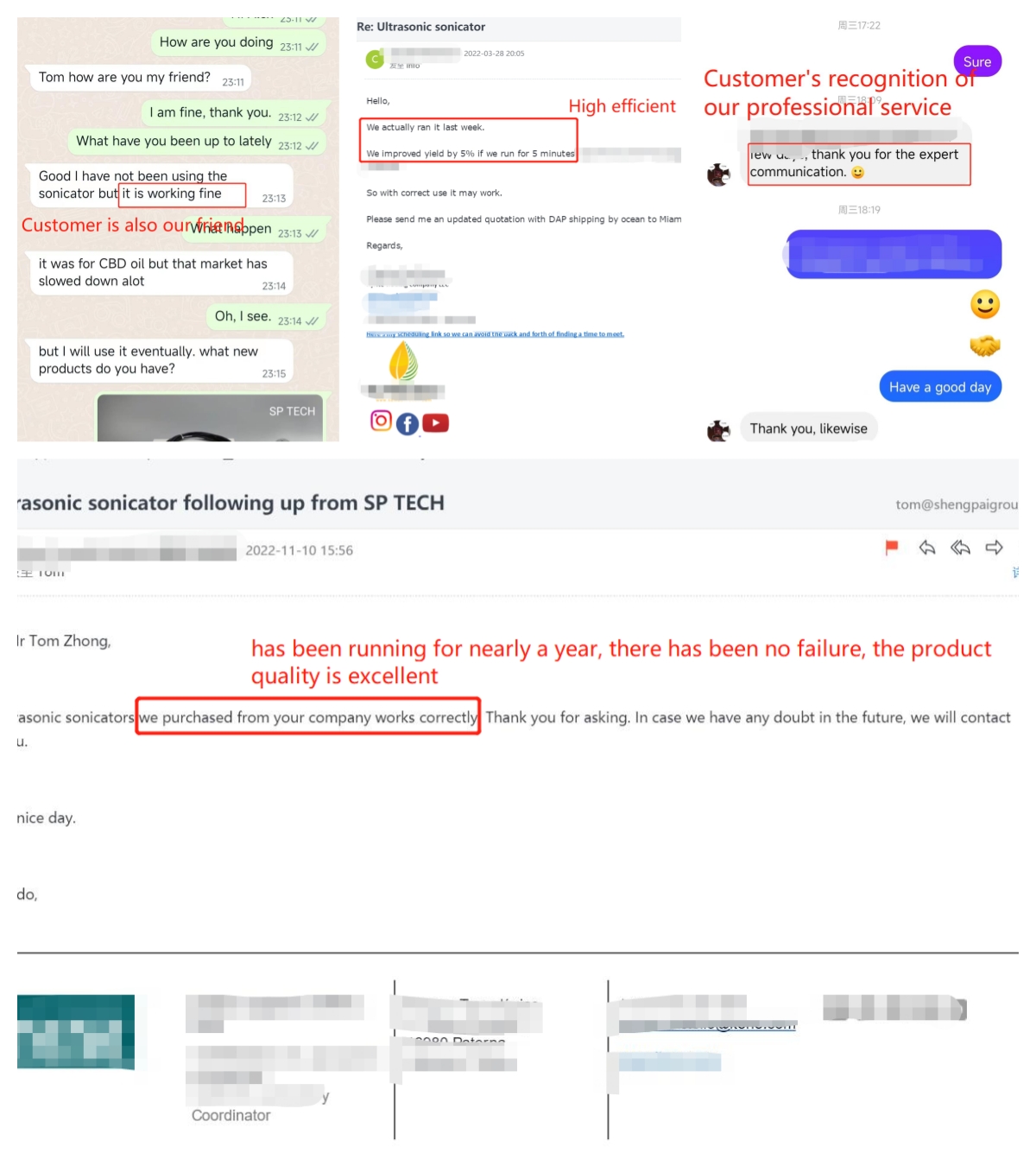

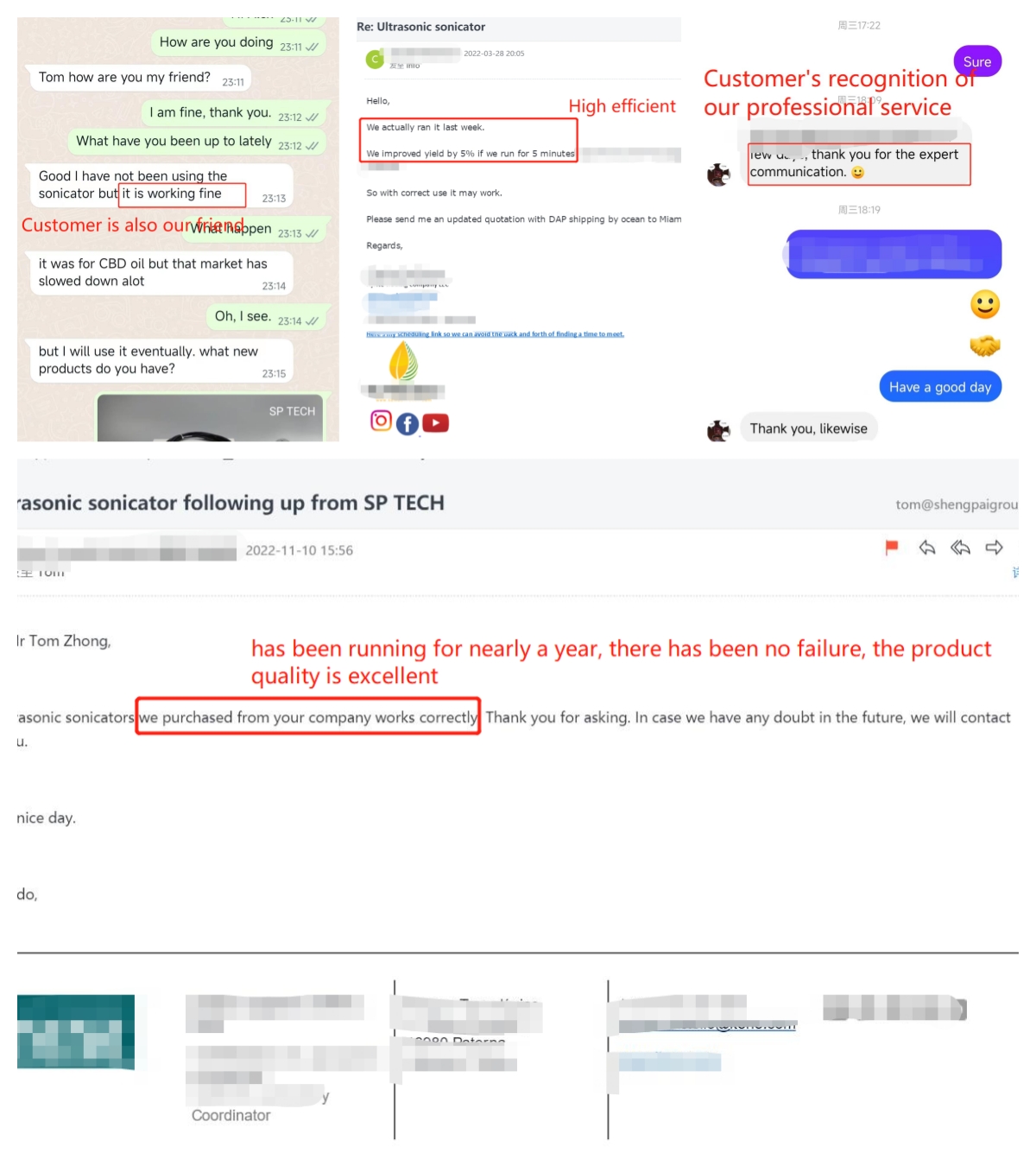

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

We have been using an ultrasonic homogenizer for protein extraction, and it has been a game-changer for our research. The homogenizer is easy to use and provides consistent results, allowing us to extract high-quality proteins from a variety of samples.

We recently purchased an ultrasonic homogenizer for plant extraction, and it has exceeded our expectations. The homogenizer is easy to use, and the results are consistent and reproducible. We have been able to extract a variety of compounds from different plant species, and the quality of the extracts is excellent.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Certain applications, such as processing nanoparticles, often require longer processing times. Using larger probes will speed up processing and larger probes will not corrode as quickly as smaller probes.

Also, smaller probes wear out faster and require more frequent replacement. Using a larger system will eventually reduce costs over time as you consider the cost of replacing multiple probes.

Prolonged sonication can cause heat to transfer up the probe to the transducer. Overheating can severely damage the transducer and ultrasound system. Samples that require continuous processing for more than 15 minutes must be air-cooled with the converter. Converter cooling is available for SPS20-1000/2000/3000 models.

The required power is selected for experimental and industrial grade equipment according to the processing capacity and materials.

Ultrasonic extraction is achieved when high-power, low-frequency ultrasound waves are coupled into a slurry consisting of botanical material in a solvent. High-power ultrasonic waves are coupled via a probe-type ultrasonic processor into the slurry. highly energetic ultrasound waves travel through the liquid creating alternating high-pressure / low-pressure cycles, which results in the phenomenon of acoustic cavitation. Acoustic or ultrasonic cavitation leads locally to extreme temperatures, pressures, heating/cooling rates, pressure differentials and high shear forces in the medium. When cavitation bubbles implode on the surface of solids (such as particles, plant cells, tissues etc.), micro-jets and interparticlular collision generate effects such as surface peeling, erosion, particle breakdown, sonoporation (the perforation of cell walls and cell membranes) and cell disruption. Additionally, the implosion of cavitation bubbles in liquid media create macro-turbulences and micro-mixing. Ultrasonic irradiation represents an efficient way to enhance mass transfer processes, since sonication results in cavitation and its related mechanisms such as micros-movement by liquid jets, compression and decompression in the material with the subsequent disruption of cell walls, as well as high heating and cooling rates. Probe-type ultrasonicators can generate very high amplitudes, which is necessary to generate impactful cavitation. SP TECH Ultrasonic manufactures high-performance ultrasonic extractors, which can easily create amplitudes of 100µm in continuous operation.

Model | SPS20-500S | SPS20-1000S | SPS20-1600S | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

Frequency | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz | 20Khz |

Power | 500 W | 1000 W | 1600 W | 2000W | 3000W | 3000 W |

Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

Pressure | Normal | Normal | Normal | 35 MPa | 35 MPa | 35 MPa |

Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 10.0 | 20.0 | 50.0 | 100.0 |

Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Pharmaceutical Industry: Enables the extraction of active compounds from medicinal herbs, facilitating the development of natural-based medications and herbal supplements.

2. Cosmetics Industry: Supports the extraction of natural ingredients for the formulation of skincare products, enhancing their efficacy and promoting the use of botanical extracts in cosmetics.

3. Food and Beverage Industry: Facilitates the extraction of flavors, colors, and bioactive compounds from herbs, enhancing the taste, appearance, and nutritional value of food and beverages.

4. Nutraceutical Industry: Assists in the extraction of bioactive compounds for the formulation of dietary supplements, promoting natural health and wellness solutions.

5. Agriculture and Horticulture: Supports research and development in plant breeding, genetic studies, and crop improvement by enabling the extraction of valuable compounds from herb tissues.

6. Essential Oil Production: Supports the extraction of essential oils from aromatic herbs, ensuring high-quality oils with preserved fragrance and therapeutic properties.

1. Ultrasonic extraction can achieve higher extraction yields in a shorter time compared to traditional extraction methods such as maceration and Soxhlet extraction.

2. Ultrasonic extraction can extract compounds within minutes to a few hours, which is much faster than traditional extraction methods that may take several days or even weeks.

3. Ultrasonic extraction can be used to extract specific compounds by adjusting the frequency, power, and duration of the sound waves. This makes it possible to selectively extract the target compounds without extracting unwanted compounds.

4. Ultrasonic extraction uses only water or other solvents, eliminating the need for toxic solvents that are harmful to the environment and human health.

5. Ultrasonic extraction is easy to scale up from laboratory to industrial production. The same equipment can be used for small-scale and large-scale production, which makes it a cost-effective extraction technique.

6. Ultrasonic extraction can extract high-quality compounds with a higher purity and better bioactivity compared to traditional extraction methods.

Customers' evalution as follow:

The ultrasonic sonicator works very well.

We improved yield by 5% if we run for 5 minutes.

We have been using an ultrasonic homogenizer for protein extraction, and it has been a game-changer for our research. The homogenizer is easy to use and provides consistent results, allowing us to extract high-quality proteins from a variety of samples.

We recently purchased an ultrasonic homogenizer for plant extraction, and it has exceeded our expectations. The homogenizer is easy to use, and the results are consistent and reproducible. We have been able to extract a variety of compounds from different plant species, and the quality of the extracts is excellent.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Certain applications, such as processing nanoparticles, often require longer processing times. Using larger probes will speed up processing and larger probes will not corrode as quickly as smaller probes.

Also, smaller probes wear out faster and require more frequent replacement. Using a larger system will eventually reduce costs over time as you consider the cost of replacing multiple probes.

Prolonged sonication can cause heat to transfer up the probe to the transducer. Overheating can severely damage the transducer and ultrasound system. Samples that require continuous processing for more than 15 minutes must be air-cooled with the converter. Converter cooling is available for SPS20-1000/2000/3000 models.

The required power is selected for experimental and industrial grade equipment according to the processing capacity and materials.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.