| Availability: | |

|---|---|

| Quantity: | |

SPS20-1000S

SP

8543709990

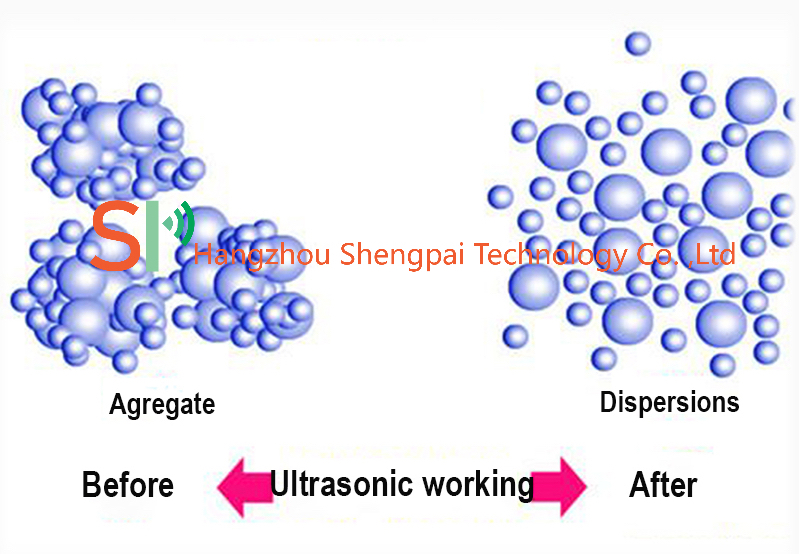

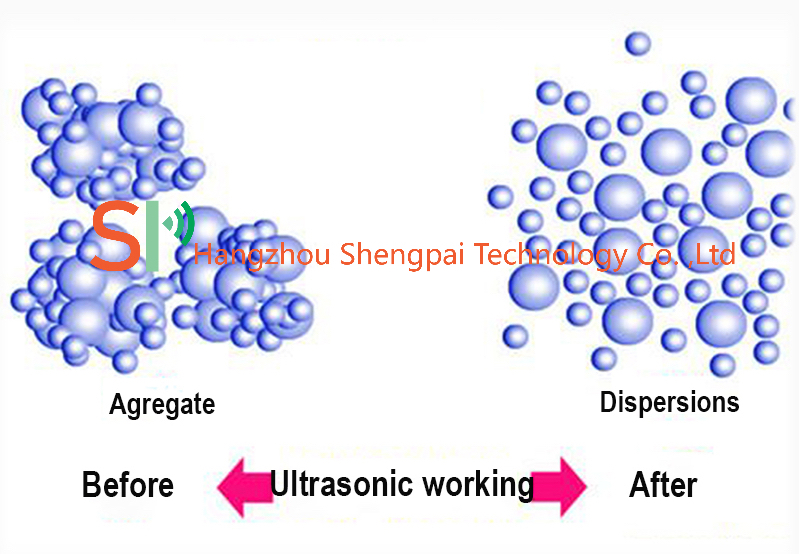

Ultrasonic homogenization is the use of ultrasonic cavitation in liquids and other physical effects to achieve homogenization. Physical action refers to the formation of an effective agitation and flow disrupting medium in the liquid, the pulverizing of the particles in the liquid, mainly the collision between the liquid, the micro phase flow and the shock wave leading to changes in the surface morphology of the particles.

Ultrasonic homogenization is the use of ultrasonic cavitation in liquids and other physical effects to achieve homogenization. Physical action refers to the formation of an effective agitation and flow disrupting medium in the liquid, the pulverizing of the particles in the liquid, mainly the collision between the liquid, the micro phase flow and the shock wave leading to changes in the surface morphology of the particles.

Ultrasonic homogenizers consist of three parts:

A generator, which supplies of energy; .

A converter, which converts electrical energy into mechanical motion.

A horn, which when placed into a liquid moves in a rapid fashion and causes bubbles to form. The expansion and contraction of these bubbles destroy the plant epidermis, and extract the cell fluid inside the plant cells into the solution, speed up the extraction process of the plant, and can obtain substances that cannot be extracted by conventional leaching methods (such as CBD).

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Compared with traditional methods under the same conditions, ultrasonic extraction has a faster reaction speed and higher extraction yield.

2. The substances extracted by ultrasonic waves are purer and of better quality.

3. Basically compatible with any solvent

4. The equipment is simple to operate, one-button start, safe and reliable

5. It has linear scalability and can be stacked with multiple devices or compatible with other devices.

6. Environmentally friendly and fast return on investment.

|  |

Customers' evalution as follow:

The ultrasonic homogenizer works very well.

When we added the equipment to our line and ran it for 60 minutes, we saw a 10% increase in output.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation

Ultrasonic homogenization is the use of ultrasonic cavitation in liquids and other physical effects to achieve homogenization. Physical action refers to the formation of an effective agitation and flow disrupting medium in the liquid, the pulverizing of the particles in the liquid, mainly the collision between the liquid, the micro phase flow and the shock wave leading to changes in the surface morphology of the particles.

Ultrasonic homogenization is the use of ultrasonic cavitation in liquids and other physical effects to achieve homogenization. Physical action refers to the formation of an effective agitation and flow disrupting medium in the liquid, the pulverizing of the particles in the liquid, mainly the collision between the liquid, the micro phase flow and the shock wave leading to changes in the surface morphology of the particles.

Ultrasonic homogenizers consist of three parts:

A generator, which supplies of energy; .

A converter, which converts electrical energy into mechanical motion.

A horn, which when placed into a liquid moves in a rapid fashion and causes bubbles to form. The expansion and contraction of these bubbles destroy the plant epidermis, and extract the cell fluid inside the plant cells into the solution, speed up the extraction process of the plant, and can obtain substances that cannot be extracted by conventional leaching methods (such as CBD).

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

1. Compared with traditional methods under the same conditions, ultrasonic extraction has a faster reaction speed and higher extraction yield.

2. The substances extracted by ultrasonic waves are purer and of better quality.

3. Basically compatible with any solvent

4. The equipment is simple to operate, one-button start, safe and reliable

5. It has linear scalability and can be stacked with multiple devices or compatible with other devices.

6. Environmentally friendly and fast return on investment.

|  |

Customers' evalution as follow:

The ultrasonic homogenizer works very well.

When we added the equipment to our line and ran it for 60 minutes, we saw a 10% increase in output.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.