| Availability: | |

|---|---|

| Quantity: | |

SPS20-3000Z

SP

8543709990

Ultrasonic extraction is the preferred technique to isolate bioactive compounds from botanicals. The ultrasonic extractor uses ultrasonic radiation pressure to cause multi-level effects such as strong cavitation, disturbance effect, high speed, destruction and mixing effect to expand the frequency and speed of molecular motion of substances, increase the penetration of organic solvents, and thereby accelerate the dissolution of the extract. Being such an efficient extraction method, ultrasonic extraction is cost- and time-saving, whilst resulting in high-quality extracts, which are used for food, supplements and pharmaceuticals.

Ultrasonic extraction occurs when high-power, low-frequency ultrasound waves are applied to a mixture of botanical material and solvent. These waves are typically delivered through a probe-type ultrasonic processor, penetrating the slurry. The intense ultrasound energy creates cycles of high and low pressure, known as acoustic cavitation, within the liquid. This phenomenon generates extreme conditions locally, including temperature spikes, pressure differentials, rapid heating and cooling, and high shear forces. When cavitation bubbles collapse near solid surfaces such as particles or plant cells, they produce micro-jets and collisions, leading to effects like surface erosion, particle breakdown, sonoporation (perforation of cell walls and membranes), and cell disruption. Moreover, the collapse of cavitation bubbles in the liquid induces macro-turbulence and micro-mixing. Ultrasonic treatment significantly enhances mass transfer processes by promoting cavitation-related mechanisms such as liquid jet movement, compression and decompression within the material, and disruption of cell walls, alongside rapid heating and cooling. Probe-type ultrasonicators are capable of generating high amplitudes necessary for impactful cavitation. SP TECH Ultrasonic manufactures high-performance ultrasonic extractors capable of continuous operation with amplitudes reaching 100µm.

Ultrasonic extraction occurs when high-power, low-frequency ultrasound waves are applied to a mixture of botanical material and solvent. These waves are typically delivered through a probe-type ultrasonic processor, penetrating the slurry. The intense ultrasound energy creates cycles of high and low pressure, known as acoustic cavitation, within the liquid. This phenomenon generates extreme conditions locally, including temperature spikes, pressure differentials, rapid heating and cooling, and high shear forces. When cavitation bubbles collapse near solid surfaces such as particles or plant cells, they produce micro-jets and collisions, leading to effects like surface erosion, particle breakdown, sonoporation (perforation of cell walls and membranes), and cell disruption. Moreover, the collapse of cavitation bubbles in the liquid induces macro-turbulence and micro-mixing. Ultrasonic treatment significantly enhances mass transfer processes by promoting cavitation-related mechanisms such as liquid jet movement, compression and decompression within the material, and disruption of cell walls, alongside rapid heating and cooling. Probe-type ultrasonicators are capable of generating high amplitudes necessary for impactful cavitation. SP TECH Ultrasonic manufactures high-performance ultrasonic extractors capable of continuous operation with amplitudes reaching 100µm.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic sonicator work well when your sample consists primarily of liquids or small particles in liquids and you need thorough homogenization.

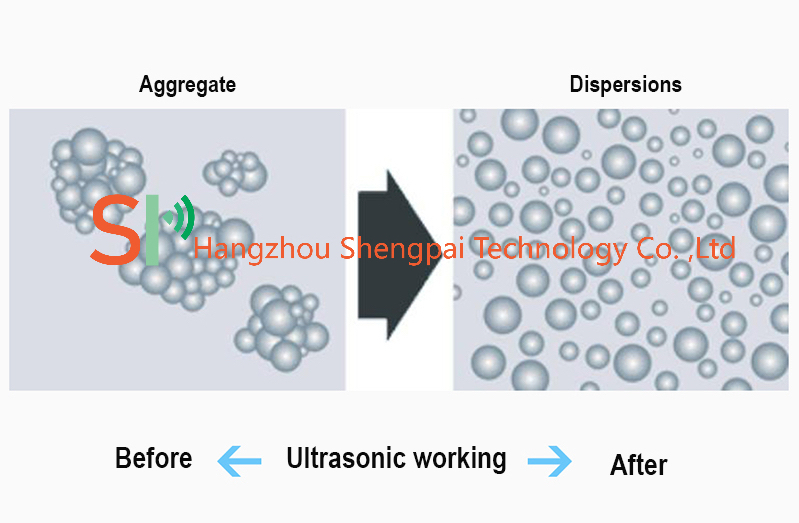

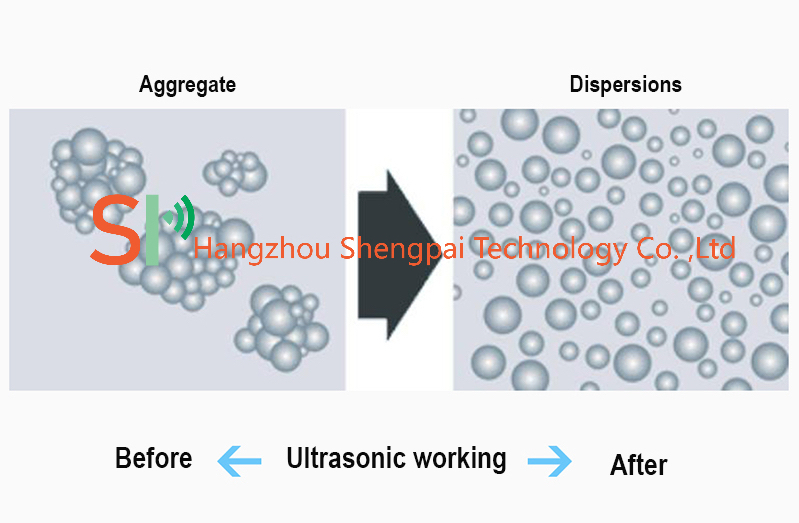

These measures include reducing particle size, destroying cells, forming emulsions and dispersing of nanoparticles or other small particles.

Ultrasonic sonicator are not suitable for applications where the sample is mostly solid and the buffer is not immersed in liquid.

For example, homogenization of large, tough tissue samples is usually possible only if the tissue is dipped prior to treatment.

Ultrasonic homogenization generates a lot of heat.

For thermal-sensitive applications (such as RNA extraction), make sure you have an effective way to cool the sample.

This technology provides a method forultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

Homogenization – making uniform mixtures of liquids or liquid suspensions.

Emulsification – processing foods, pharmaceuticals, and cosmetics.

Dissolution – dissolving solids in solvents.

Degassing – removing gases from solutions without heat or vacuum

Customers' evalution as follow:

The ultrasonic sonicator works very well.

After replacing the ultrasonic equipment to extract herbs, our dosage of pharmaceuticals was greatly reduced, which directly reduced our production costs. And the purity of the liquid obtained by the extraction is better than the purity we obtained before.

The ultrasonic homogenizer is a great tool for cell disruption and sample preparation. It's easy to use and produces consistent results. I would highly recommend it.

The ultrasonic homogenizer is a powerful tool that can be tricky to use. It took some trial and error to get the settings right, but once I did, it worked perfectly.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Ultrasonic extraction is the preferred technique to isolate bioactive compounds from botanicals. The ultrasonic extractor uses ultrasonic radiation pressure to cause multi-level effects such as strong cavitation, disturbance effect, high speed, destruction and mixing effect to expand the frequency and speed of molecular motion of substances, increase the penetration of organic solvents, and thereby accelerate the dissolution of the extract. Being such an efficient extraction method, ultrasonic extraction is cost- and time-saving, whilst resulting in high-quality extracts, which are used for food, supplements and pharmaceuticals.

Ultrasonic extraction occurs when high-power, low-frequency ultrasound waves are applied to a mixture of botanical material and solvent. These waves are typically delivered through a probe-type ultrasonic processor, penetrating the slurry. The intense ultrasound energy creates cycles of high and low pressure, known as acoustic cavitation, within the liquid. This phenomenon generates extreme conditions locally, including temperature spikes, pressure differentials, rapid heating and cooling, and high shear forces. When cavitation bubbles collapse near solid surfaces such as particles or plant cells, they produce micro-jets and collisions, leading to effects like surface erosion, particle breakdown, sonoporation (perforation of cell walls and membranes), and cell disruption. Moreover, the collapse of cavitation bubbles in the liquid induces macro-turbulence and micro-mixing. Ultrasonic treatment significantly enhances mass transfer processes by promoting cavitation-related mechanisms such as liquid jet movement, compression and decompression within the material, and disruption of cell walls, alongside rapid heating and cooling. Probe-type ultrasonicators are capable of generating high amplitudes necessary for impactful cavitation. SP TECH Ultrasonic manufactures high-performance ultrasonic extractors capable of continuous operation with amplitudes reaching 100µm.

Ultrasonic extraction occurs when high-power, low-frequency ultrasound waves are applied to a mixture of botanical material and solvent. These waves are typically delivered through a probe-type ultrasonic processor, penetrating the slurry. The intense ultrasound energy creates cycles of high and low pressure, known as acoustic cavitation, within the liquid. This phenomenon generates extreme conditions locally, including temperature spikes, pressure differentials, rapid heating and cooling, and high shear forces. When cavitation bubbles collapse near solid surfaces such as particles or plant cells, they produce micro-jets and collisions, leading to effects like surface erosion, particle breakdown, sonoporation (perforation of cell walls and membranes), and cell disruption. Moreover, the collapse of cavitation bubbles in the liquid induces macro-turbulence and micro-mixing. Ultrasonic treatment significantly enhances mass transfer processes by promoting cavitation-related mechanisms such as liquid jet movement, compression and decompression within the material, and disruption of cell walls, alongside rapid heating and cooling. Probe-type ultrasonicators are capable of generating high amplitudes necessary for impactful cavitation. SP TECH Ultrasonic manufactures high-performance ultrasonic extractors capable of continuous operation with amplitudes reaching 100µm.

| Model | SPS20-500S | SPS20-1000S | SPS20-1000 | SPS20-2000 | SPS20-3000 | SPS20-3000Z |

| Frequency | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz | 20KHz |

| Power | 500Watt | 1000Watt | 1000Watt | 2000Watt | 3000Watt | 3000Watt |

| Voltage | 220V | 220V | 220V | 220V | 220V | 220V |

| Pressure | Normal | Normal | Normal | Normal | Normal | Normal |

| Intensity of sound | >10 W/cm² | >10 W/cm² | >10 W/cm² | >40 W/cm² | >60 W/cm² | >60 W/cm² |

Processing capacity (L/H) | 0.5-2.0 | 1.0-4.0 | 5.0 | 20.0 | 50.0 | 100.0 |

| Material of probe | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

| Generator | Digital type | Digital type | Digital type | Digital type | Digital type | Digital type |

Ultrasonic sonicator work well when your sample consists primarily of liquids or small particles in liquids and you need thorough homogenization.

These measures include reducing particle size, destroying cells, forming emulsions and dispersing of nanoparticles or other small particles.

Ultrasonic sonicator are not suitable for applications where the sample is mostly solid and the buffer is not immersed in liquid.

For example, homogenization of large, tough tissue samples is usually possible only if the tissue is dipped prior to treatment.

Ultrasonic homogenization generates a lot of heat.

For thermal-sensitive applications (such as RNA extraction), make sure you have an effective way to cool the sample.

This technology provides a method forultrasonically lysing cells and spores in a liquid flowing continuously or intermittently through a cylindrical reactor.

Homogenization – making uniform mixtures of liquids or liquid suspensions.

Emulsification – processing foods, pharmaceuticals, and cosmetics.

Dissolution – dissolving solids in solvents.

Degassing – removing gases from solutions without heat or vacuum

Customers' evalution as follow:

The ultrasonic sonicator works very well.

After replacing the ultrasonic equipment to extract herbs, our dosage of pharmaceuticals was greatly reduced, which directly reduced our production costs. And the purity of the liquid obtained by the extraction is better than the purity we obtained before.

The ultrasonic homogenizer is a great tool for cell disruption and sample preparation. It's easy to use and produces consistent results. I would highly recommend it.

The ultrasonic homogenizer is a powerful tool that can be tricky to use. It took some trial and error to get the settings right, but once I did, it worked perfectly.

You have been most kind and helpful. Thank you for your expert communication.

Customers' recognition and trust is our driving force.

Shengpai Technology relies on “Customer Service Being First” as its corporate culture. Aim is ”Quality First, Service First”. Today, because of its abundant professional knowledge and good after-sales service, Shengpai Technology has gained a very good reputation.

Address: No.30 DATANG VILLAGE FUYANG DISTRICT HANGZHOU CITY ZHEJIANG PROVINCE CHINA

Email: info@shengpaigroup.com

Tel: 0086-571-63127797

Mobile: 0086-15888033040

0086-15355441892

NEWSLETTER

Signup to be the first to know about discounts and new product releases.